Patents

Literature

54results about How to "Reduce replacement and maintenance costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

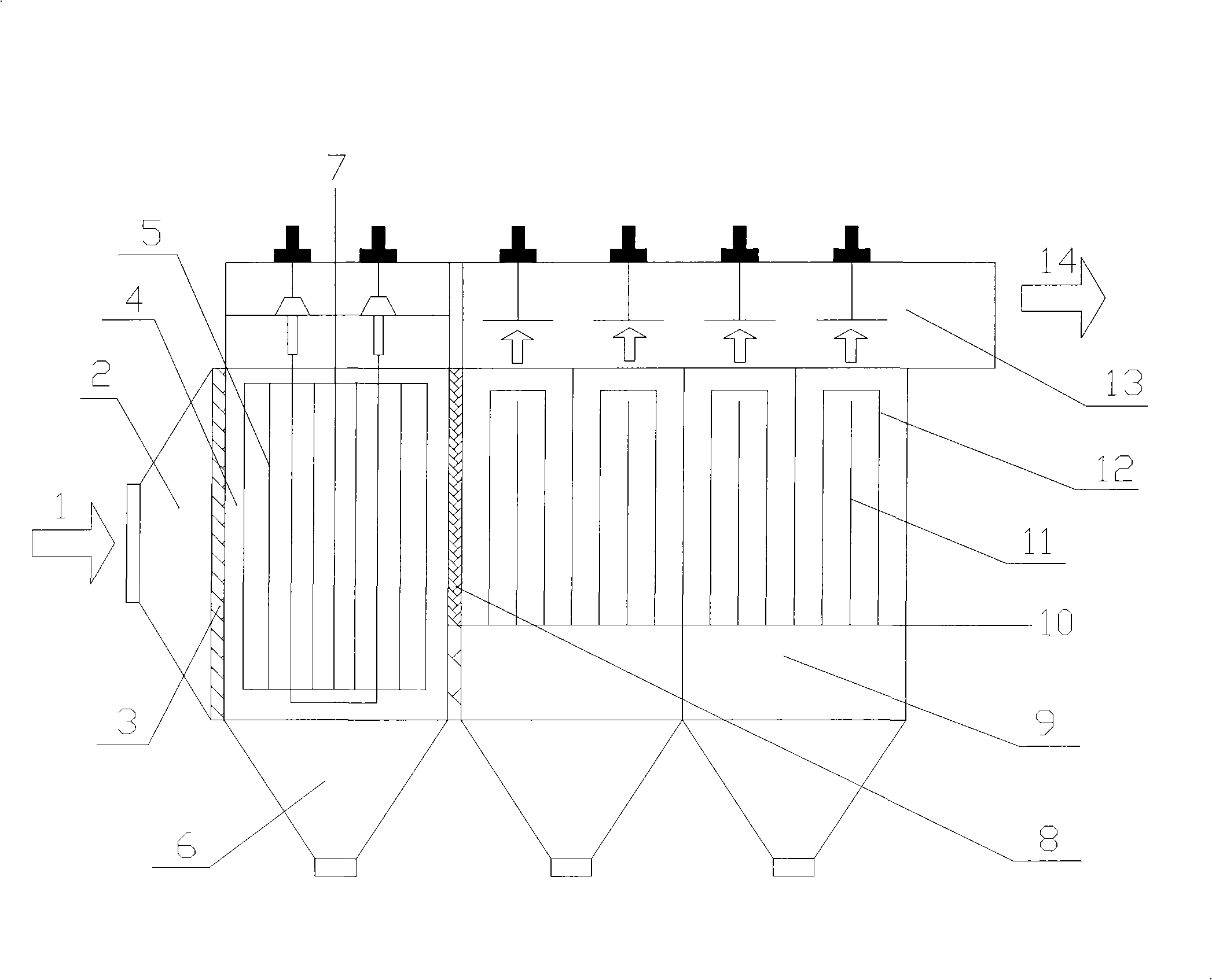

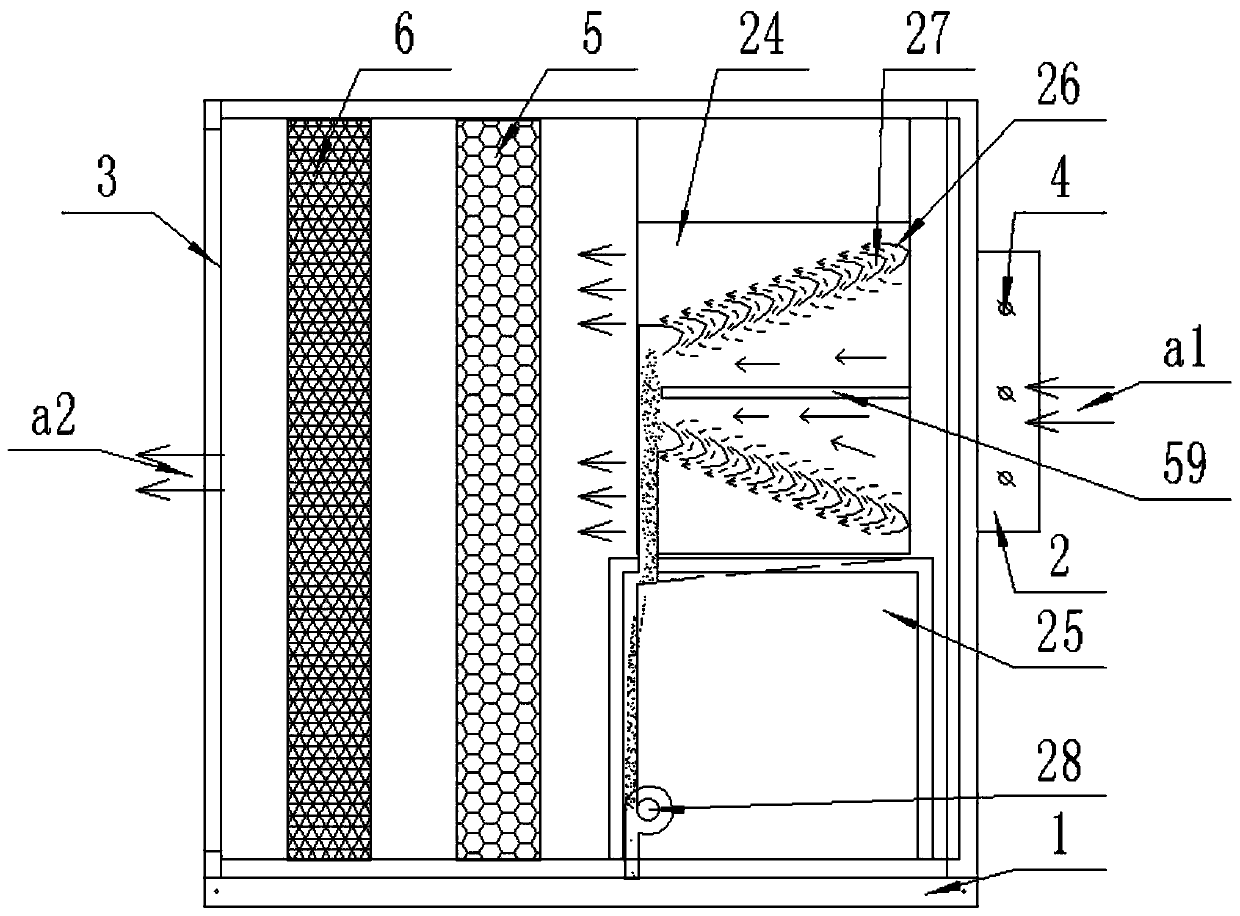

Electrostatic-filtering type combined dust-cleaning equipment

InactiveCN101406785AReduce loadExtend cleaning cycleCombination devicesElectrostatic separationElectrostatic precipitatorEngineering

The invention discloses an electrostatic-filter compound dust remover. The dust remover consists of an electrostatic dust remover and a cloth bag dust remover which are connected in series and arranged in a shell; the front end of the electrostatic dust remover is provided with a smoke inlet; an inlet smoke box and a smoke uniform distribution device in turn; the back end of the cloth bag dust remover is connected with an outlet smoke box and a smoke outlet in turn; a guide and uniform distribution device is arranged between the electrostatic dust remover and the cloth bag dust remover; the bottoms of the electrostatic dust remover and the cloth bag dust remover are provided with a dust hopper respectively; the electrostatic dust remover is provided with a direct current electrode which is connected with a negative high-voltage direct prior supply; the cloth bag dust remover is provided with an alternating current electrode and a filter bag; and the alternating current electrode is connected with a high-voltage alternating prior power. The electrostatic-filter compound dust remover combines the advantages of the electrostatic dust remover and the cloth bag dust remover, has high dust removing efficiency, especially improves the dust removing efficiency of nano-scale dust, has low filter bag resistance (lower than 1,000 Pa), adapts to the changes of various working conditions, and can meet high standard discharge requirement (smaller than 50 mg / Nm<3>).

Owner:ZHEJIANG UNIV

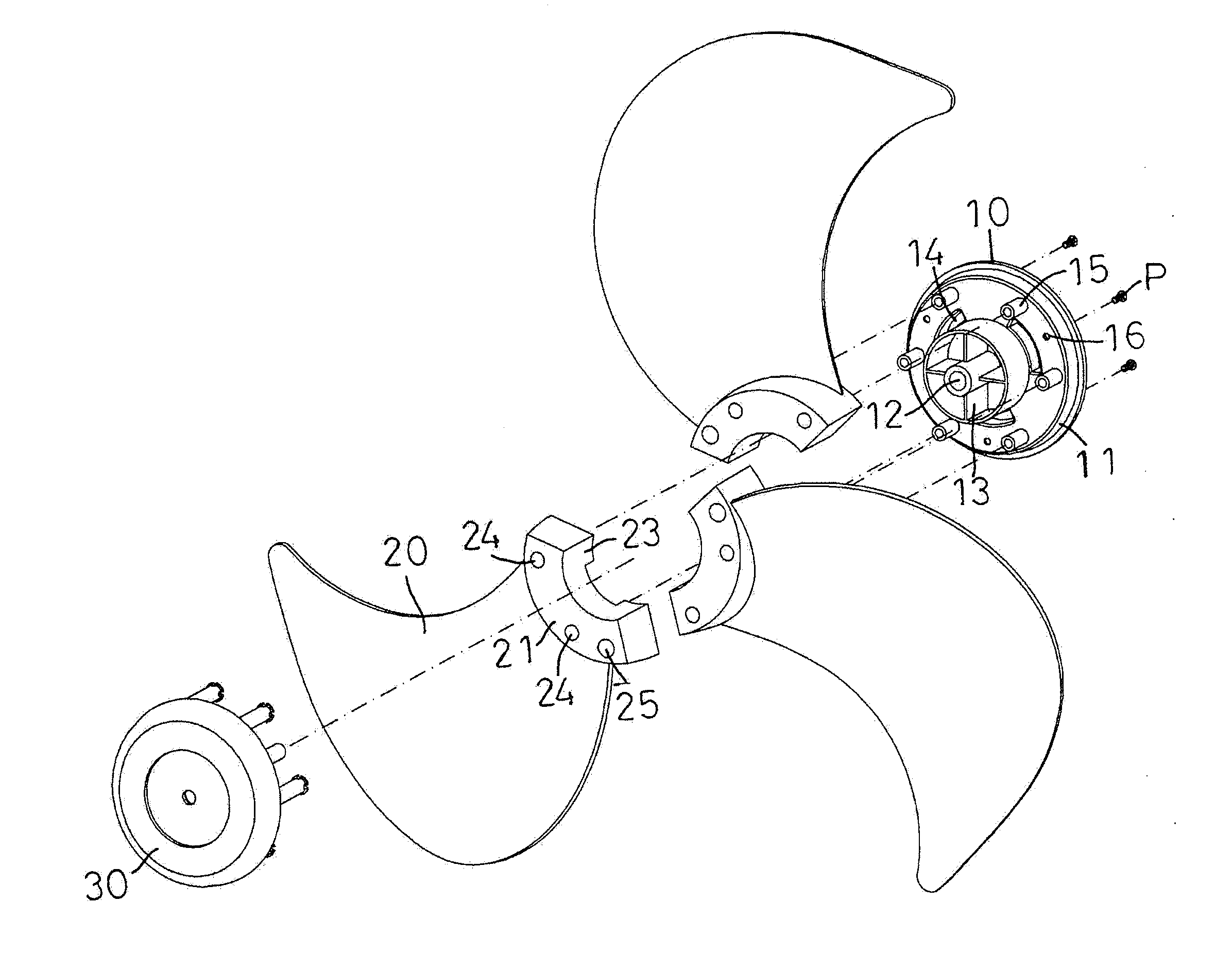

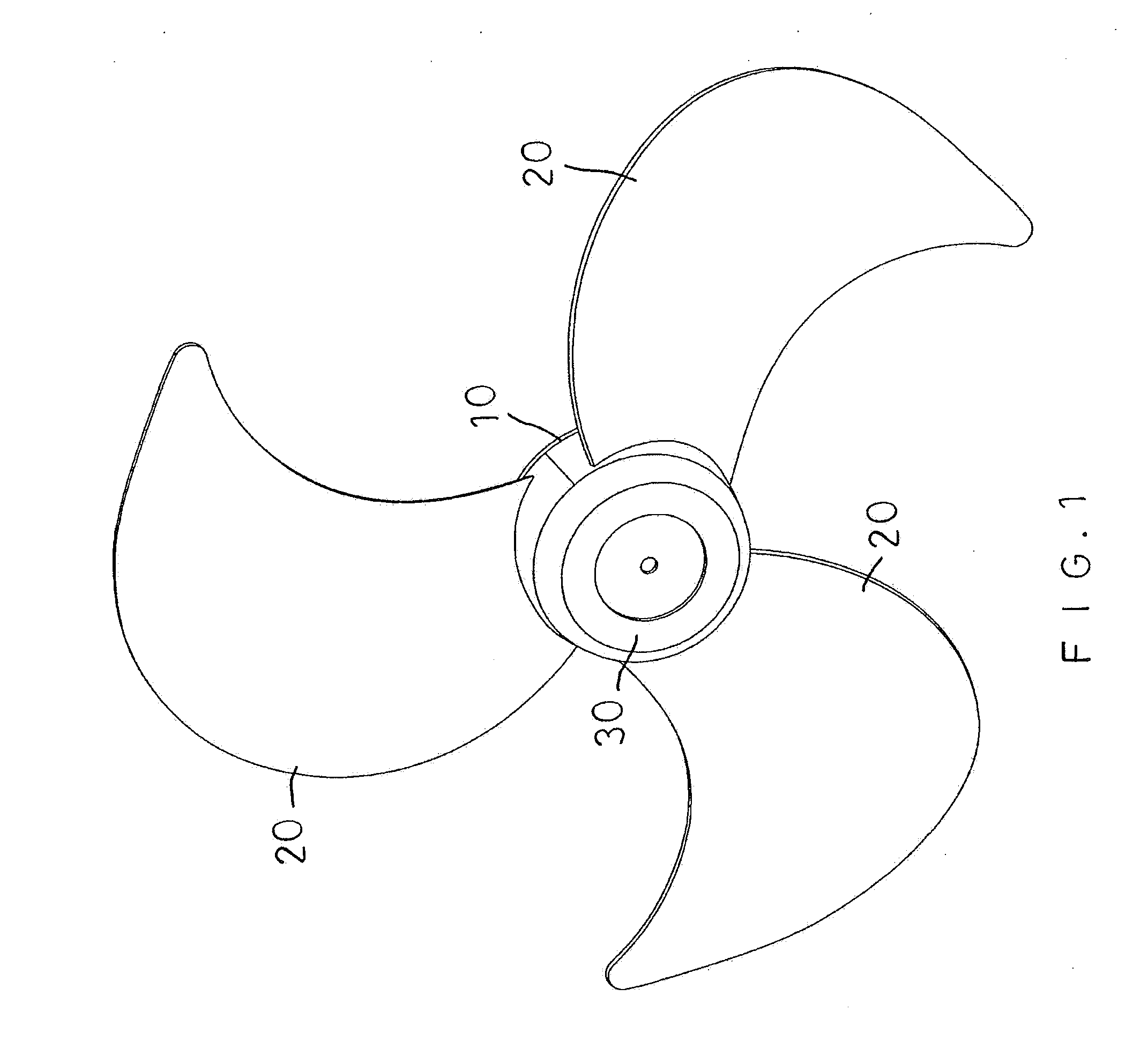

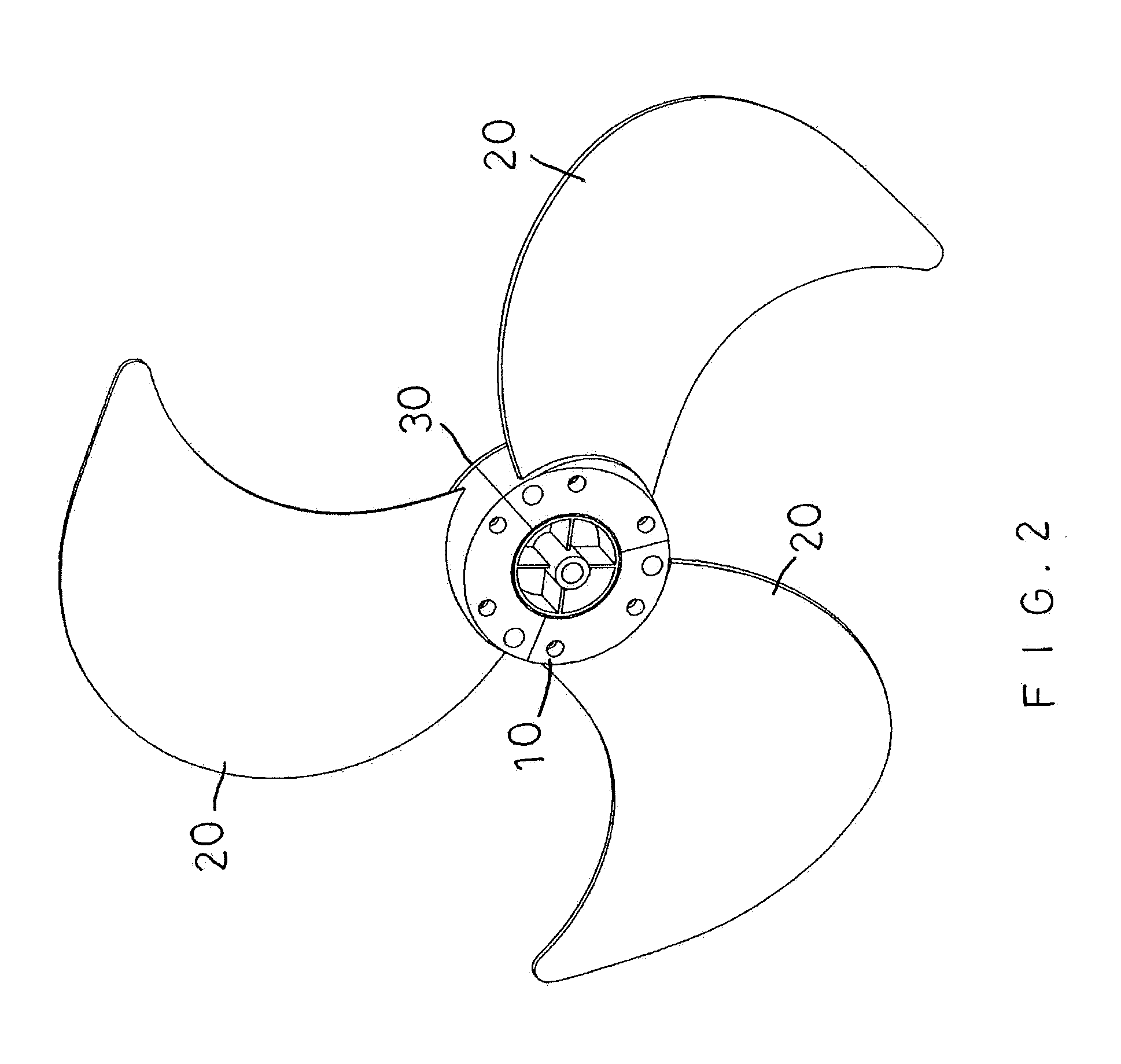

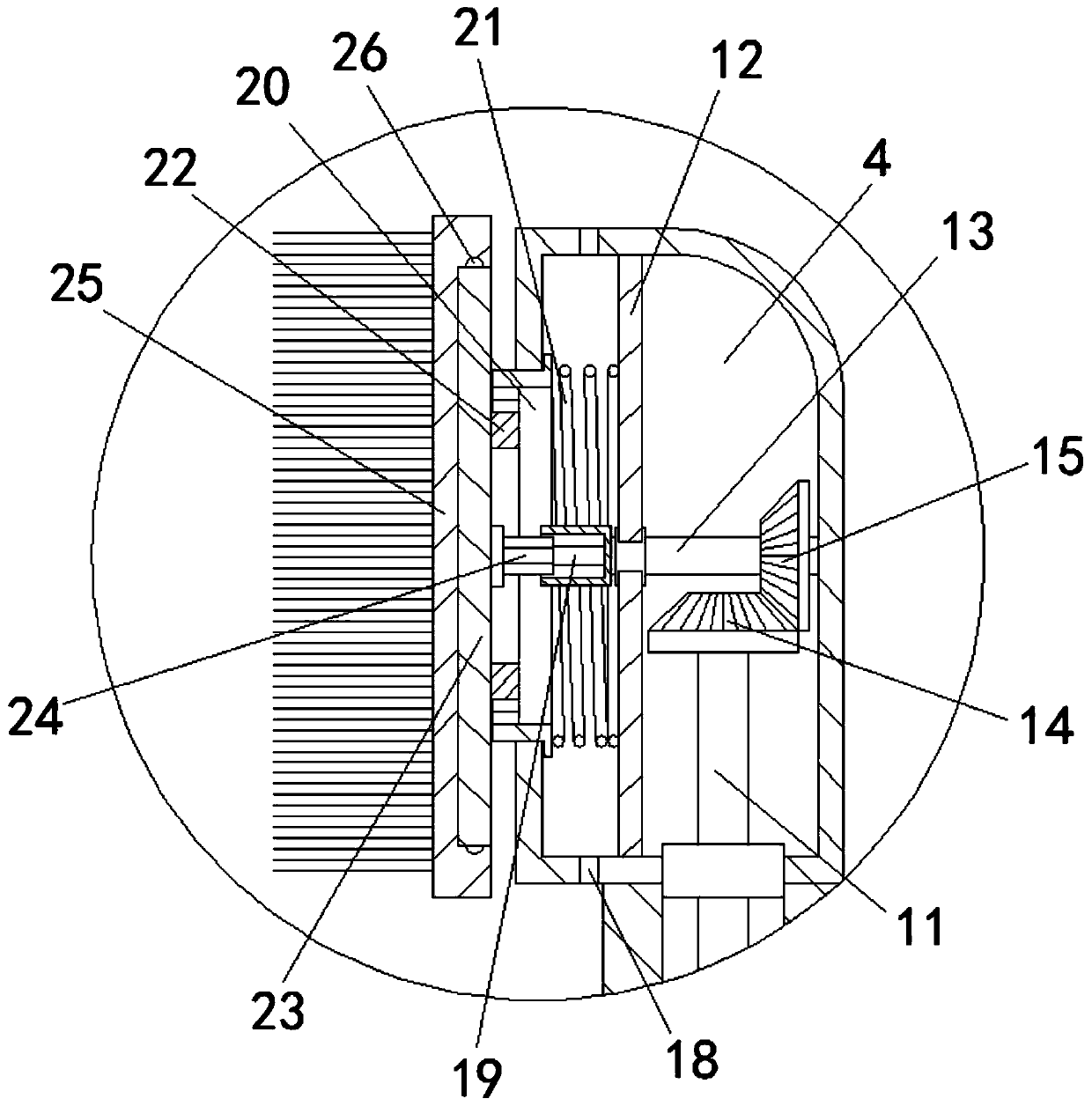

Fan Blade Assembly

ActiveUS20130336797A1Lower the volumeReduce manufacturing costPropellersPump componentsFan bladeEngineering

A fan blade assembly includes multiple blades sandwiched between a base and a cap. The base has a hollow shaft and has multiple mounting slots, positioning tubes and fixing holes. Each of the blades has a mounting seat having two lugs. The lugs of any two adjacent blades are inserted into the respective mounting slot. The mounting seat has at least one first through hole to allow insertion of the respective positioning tube, and has at least one second through hole. The cap has a mounting sleeve mounted on the shaft, multiple positioning posts each inserted into the respective first through hole and multiple threaded tubes each inserted into the respective second through hole. The fan blade assembly also includes multiple fastening screws each extended through the respective fixing hole and each screwed into the respective threaded tube.

Owner:WANG FRANK

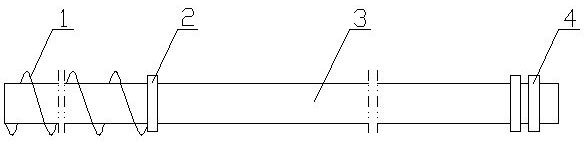

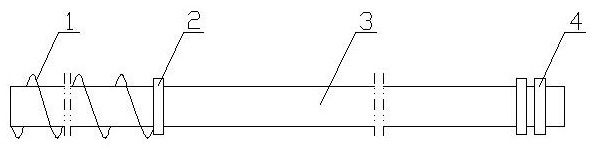

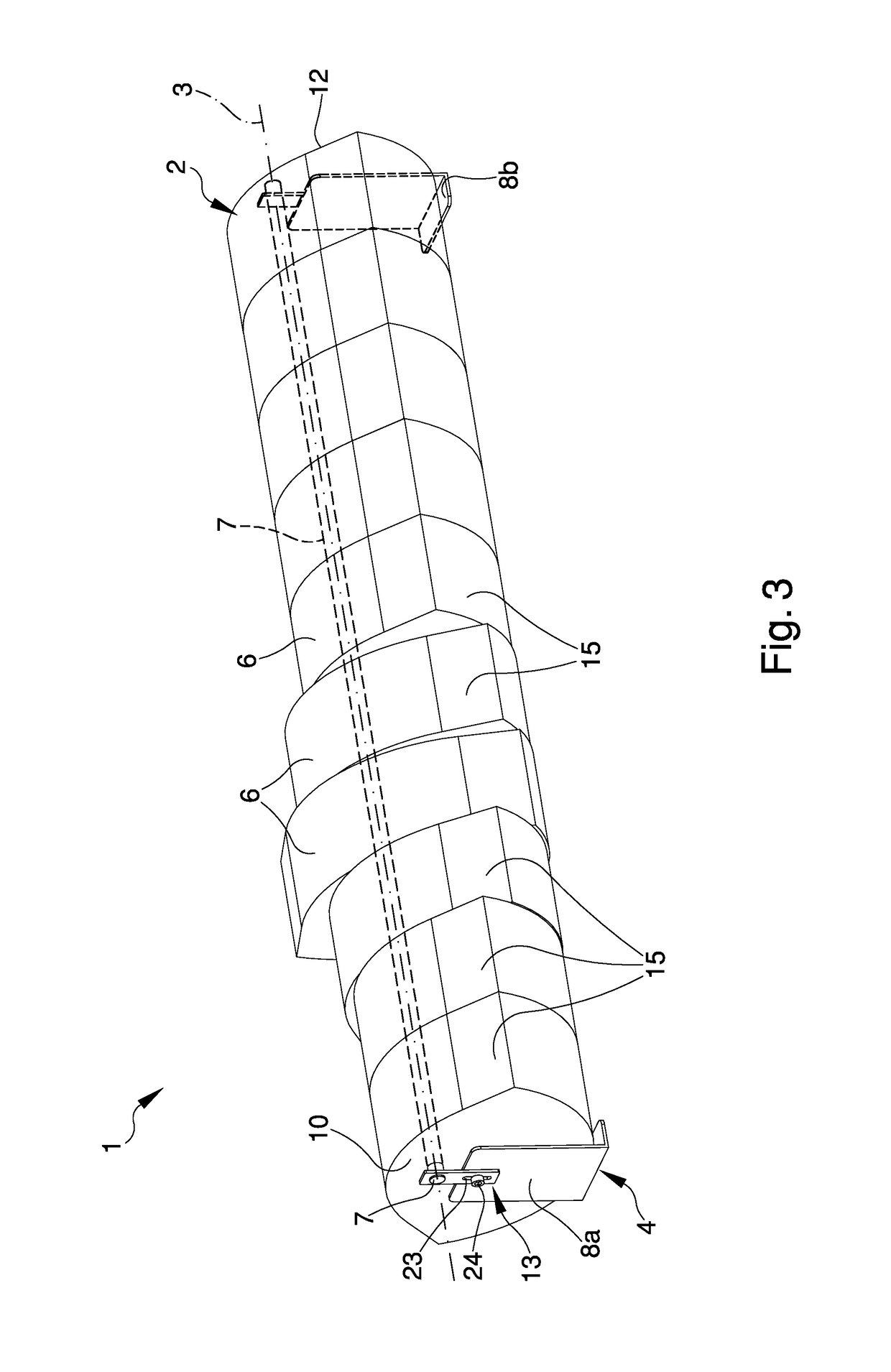

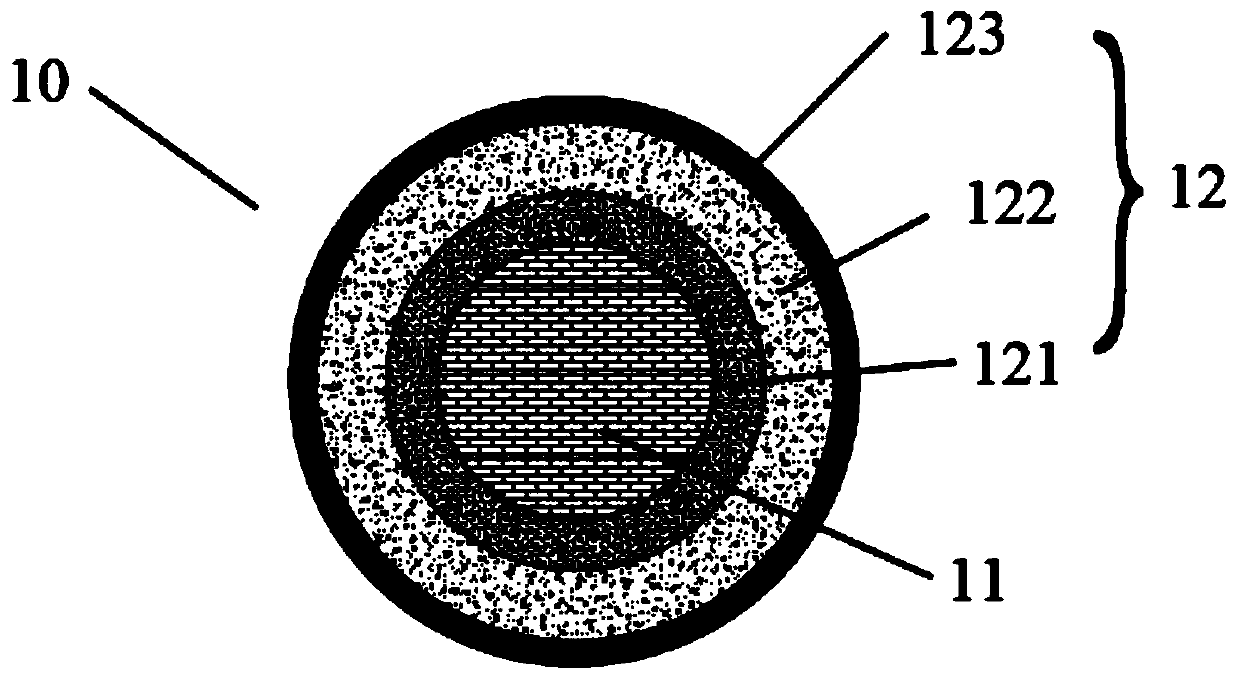

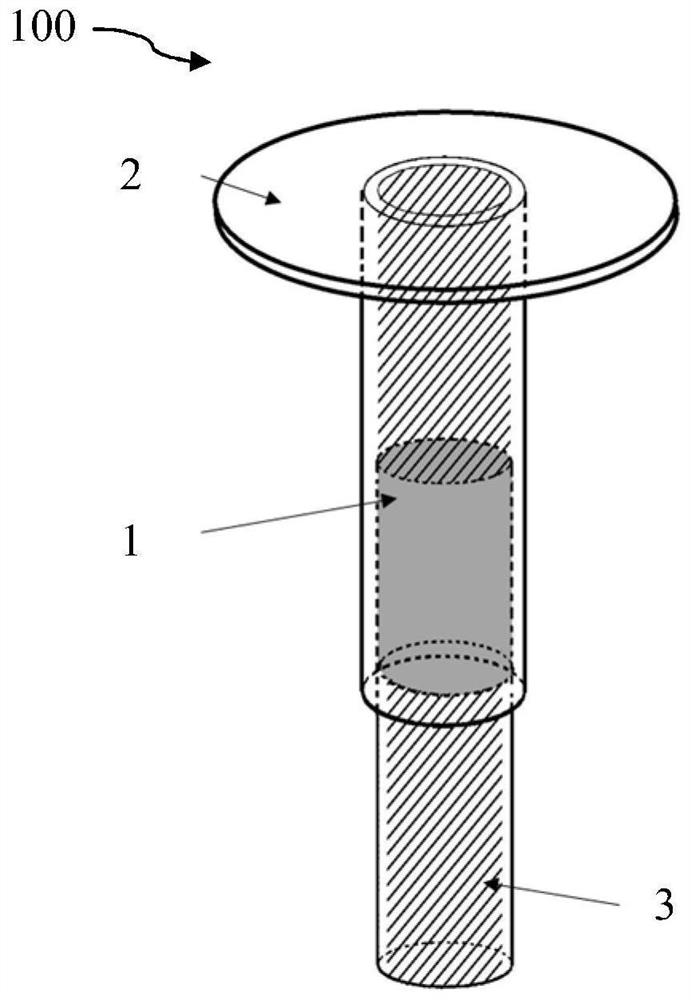

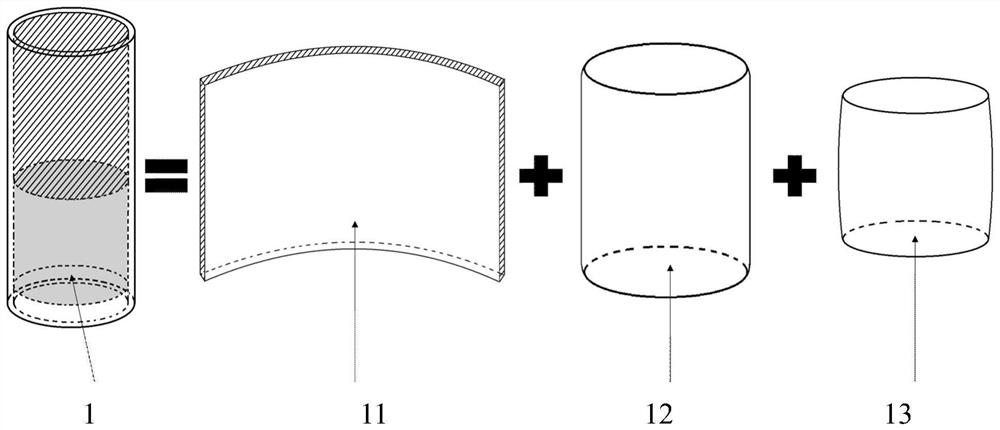

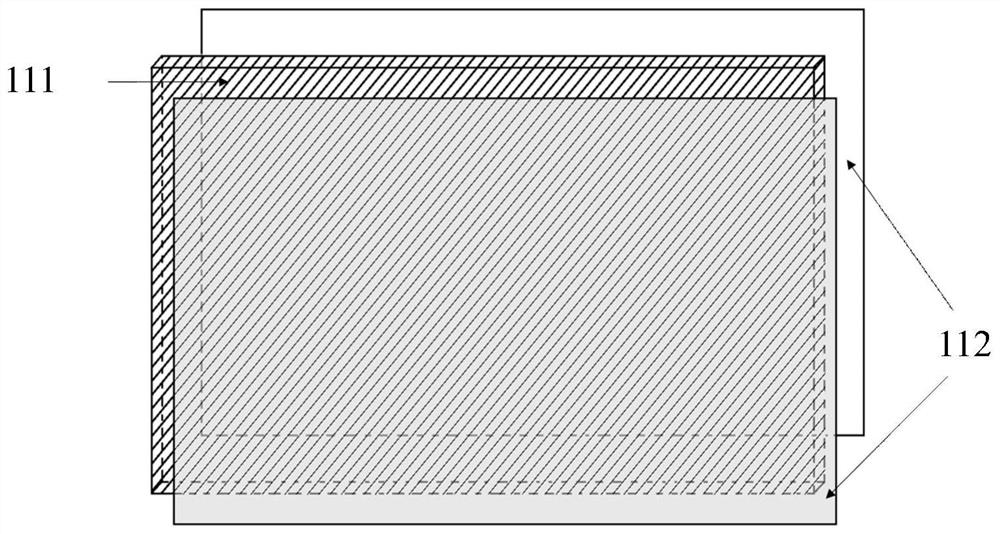

Aquiculture stay bar and production method thereof

ActiveCN102415328AReasonable structureStable supportCultivating equipmentsSeaweed cultivationTemperature resistanceSalt resistance

The invention relates to an aquiculture stay bar, which comprises a bar body. The aquiculture stay bar is characterized in that the bar body is a hollow bar body; a spirally-arranged spiral piece is fixedly arranged at the lower part of the bar body; a limiting tray is fixedly arranged on the bar body above the spiral piece; and a rope knot fixing piece is fixedly arranged at the upper part of the bar body. The invention further discloses a production method of the aquiculture stay bar. The production method is characterized in that the aquiculture stay bar is produced by extruding and forming through a die, taking m-benzene type unsaturated polyester resin and the like as base materials, taking alkali-free twistless glass fiber roving as a radial framework, taking a polyester composite felt as a weft covered felt and taking hemming felts as a weft sandwich felt and a weft inner felt. The aquiculture stay bar has the advantages of reasonable structure, firmness in support, no floating, lightness in inserting into mud, capability of rotating, high firmness, light weight, high elasticity, strength which is 3-5 times that of a bamboo pole, low possibility of breaking off, favorable acid and alkali and salt resistance, insolubility, favorable temperature resistance, ageing resistance, no pollution, capable of being repaired and long service life.

Owner:江苏创晖复合材料有限公司

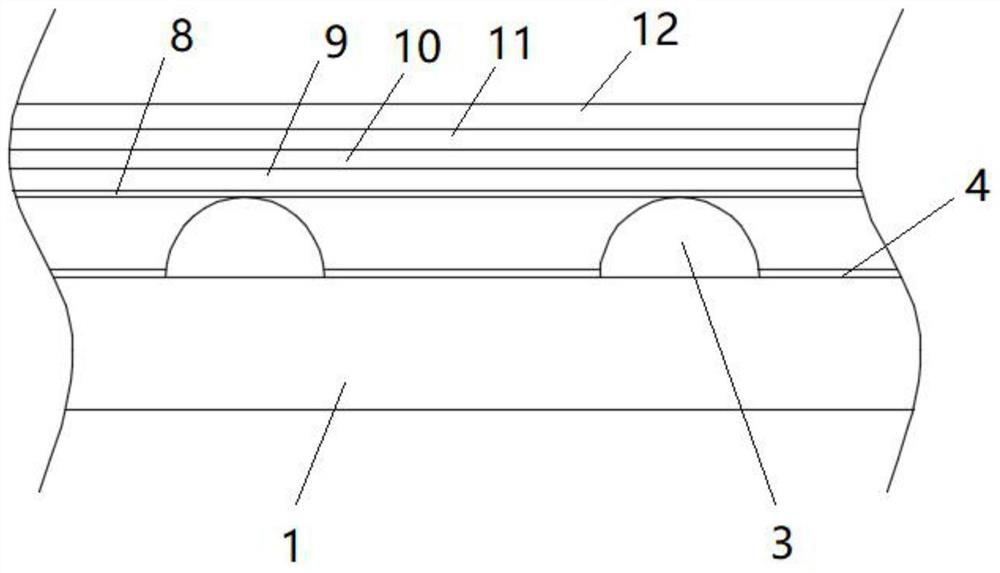

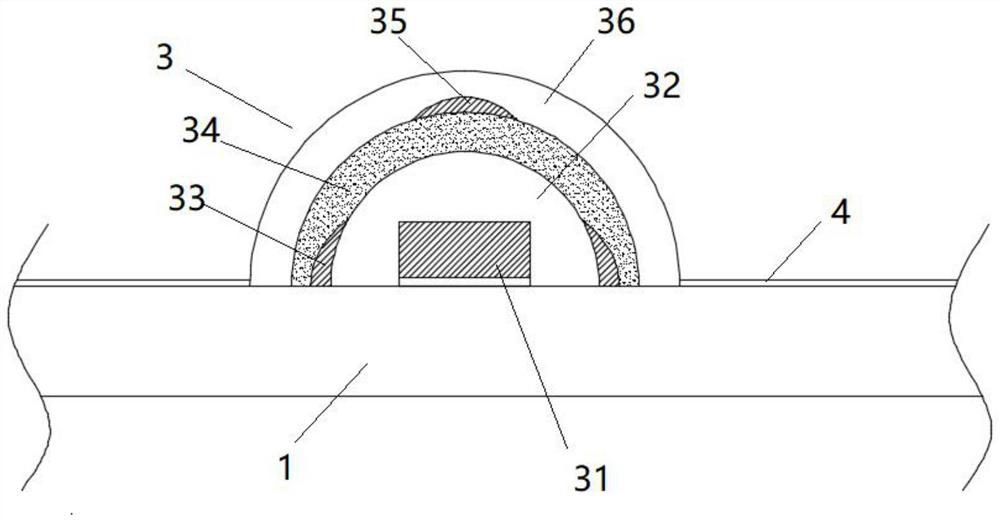

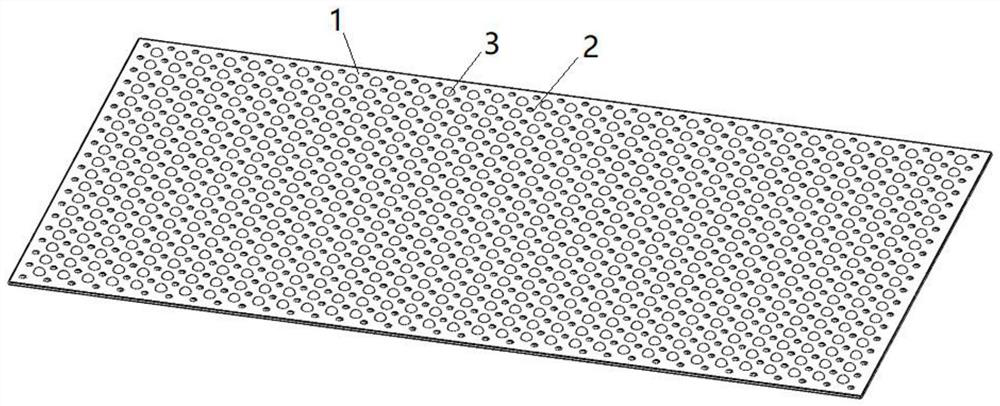

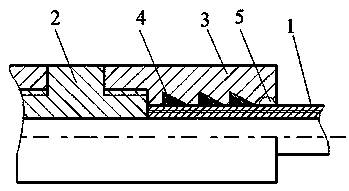

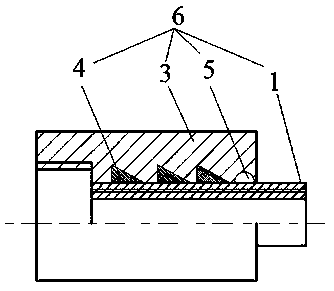

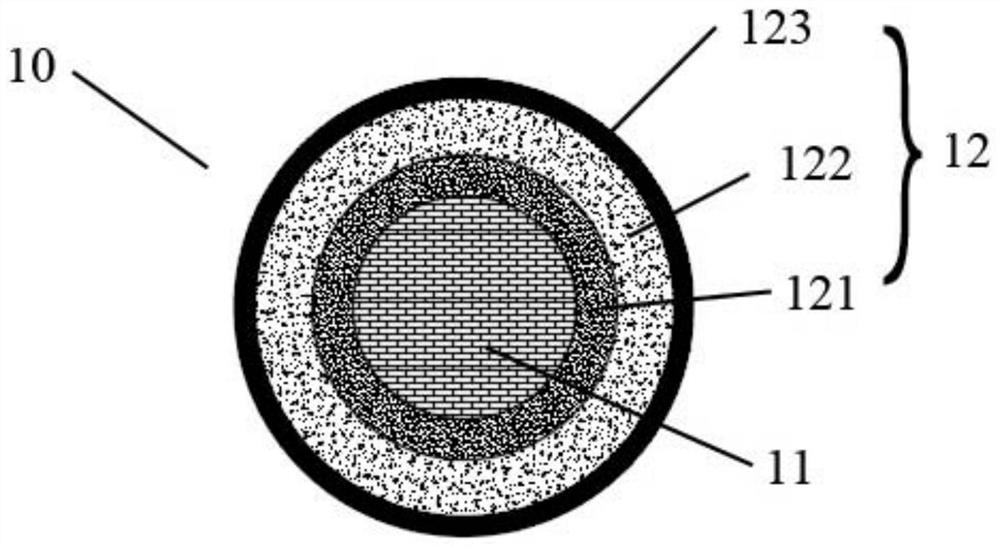

Near-zero OD backlight module and Mini LED lamp bead manufacturing method thereof

PendingCN113671751AReduce thicknessReduce process stepsNon-linear opticsSemiconductor devicesPhysical chemistryQuantum dot

The invention discloses a near-zero OD backlight module and a Mini LED lamp bead manufacturing method thereof. The backlight module comprises a PCB, lens machining adsorption holes, Mini LED lamp beads, reflection paper, a diffusion sheet, a diffusion plate, a quantum dot film, a prismatic lens and a liquid crystal screen. A back plate is arranged on the back of the PCB, and a diffusion sheet, a diffusion plate, a quantum dot film, a prismatic lens and a liquid crystal screen are sequentially arranged above the PCB; each Mini LED lamp bead comprises a Mini LED chip and a lens, the Mini LED chip is welded on an LED chip bonding pad of the PCB, and the lens wraps the Mini LED chip; the top of the lens is directly contacted with the diffusion sheet; the lens is prepared by curing organic silica gel, the viscosity of the organic silica gel is 4000-22000 Pa.s, and the hardness of the cured organic silica gel is Shore D60. The near-zero OD backlight module has the advantages that the thickness of the backlight module is reduced, the process steps are reduced, the production cost is reduced, meanwhile, the productivity is improved, lenses of different structural shapes are formed, modular production is achieved, and the replacement and maintenance cost is reduced.

Owner:ANHUI COREACH TECH

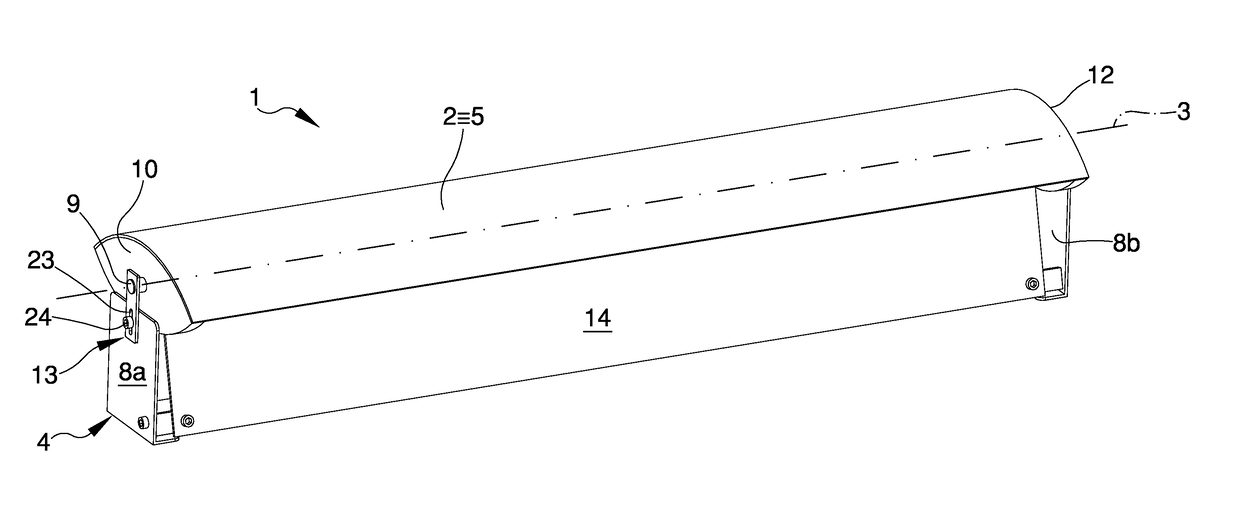

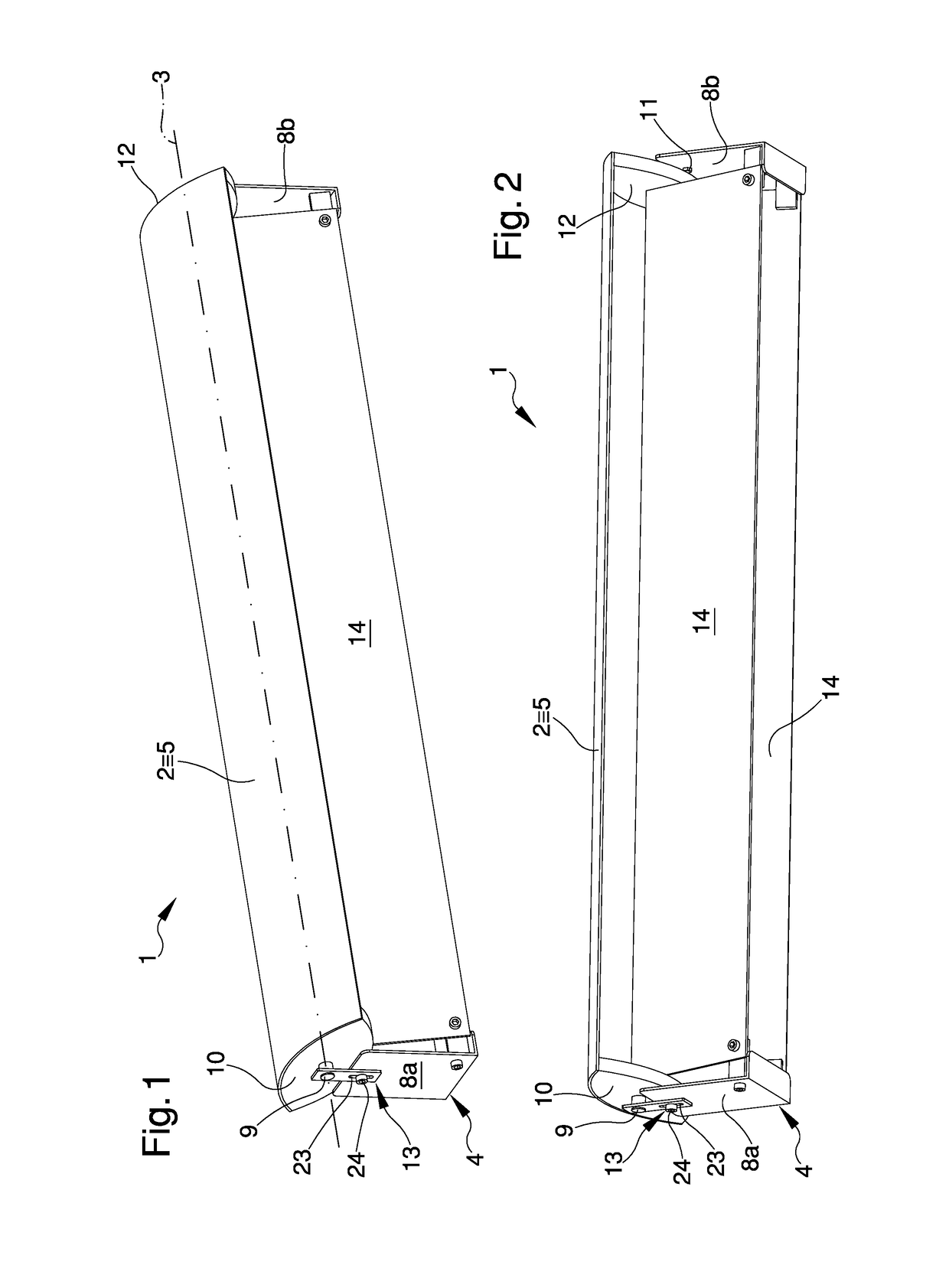

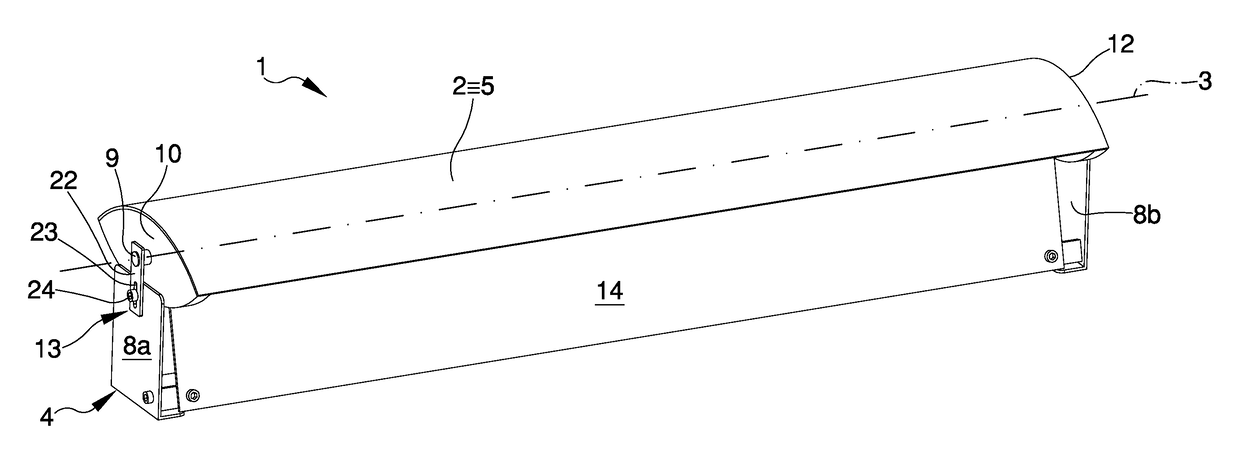

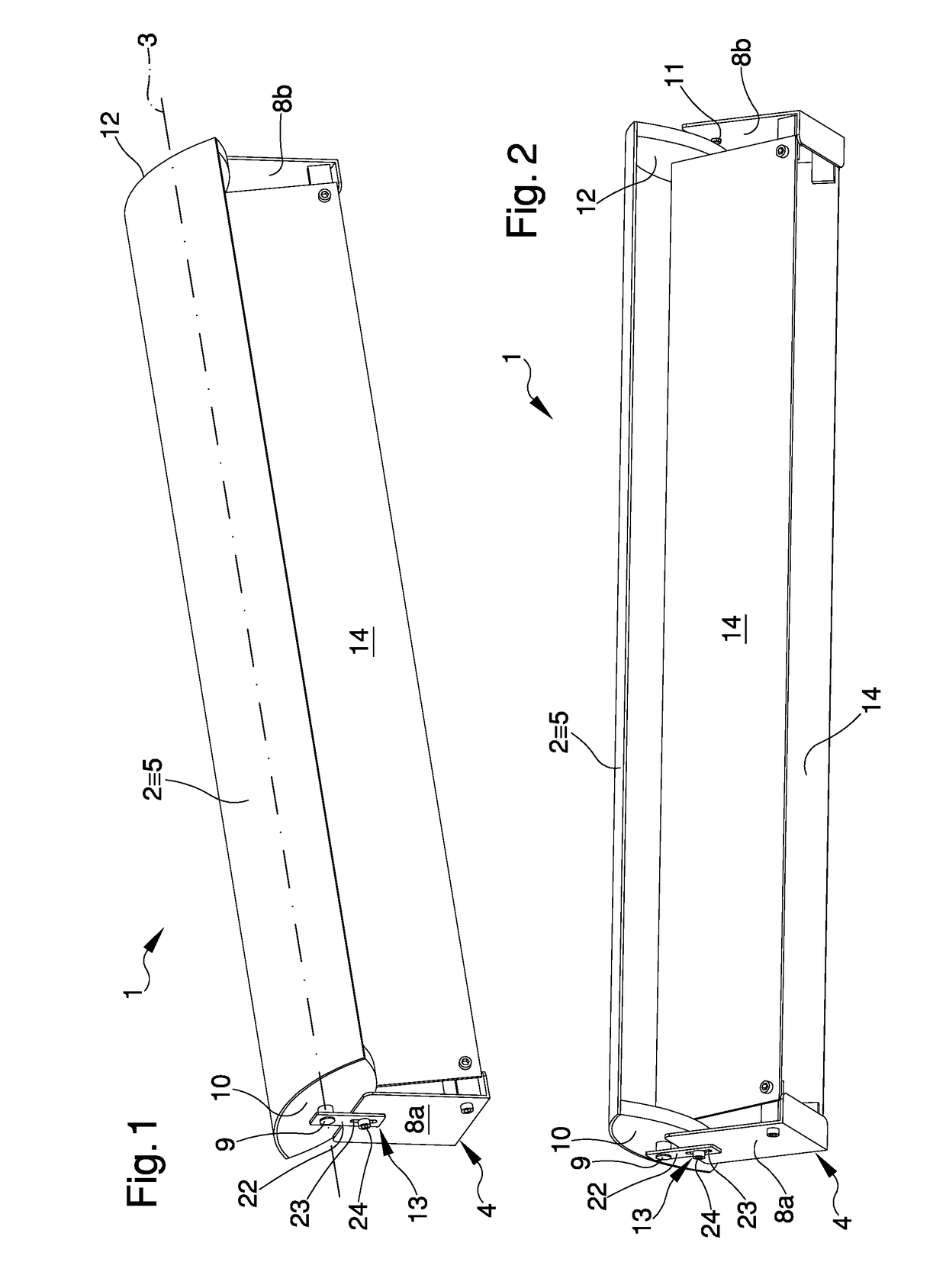

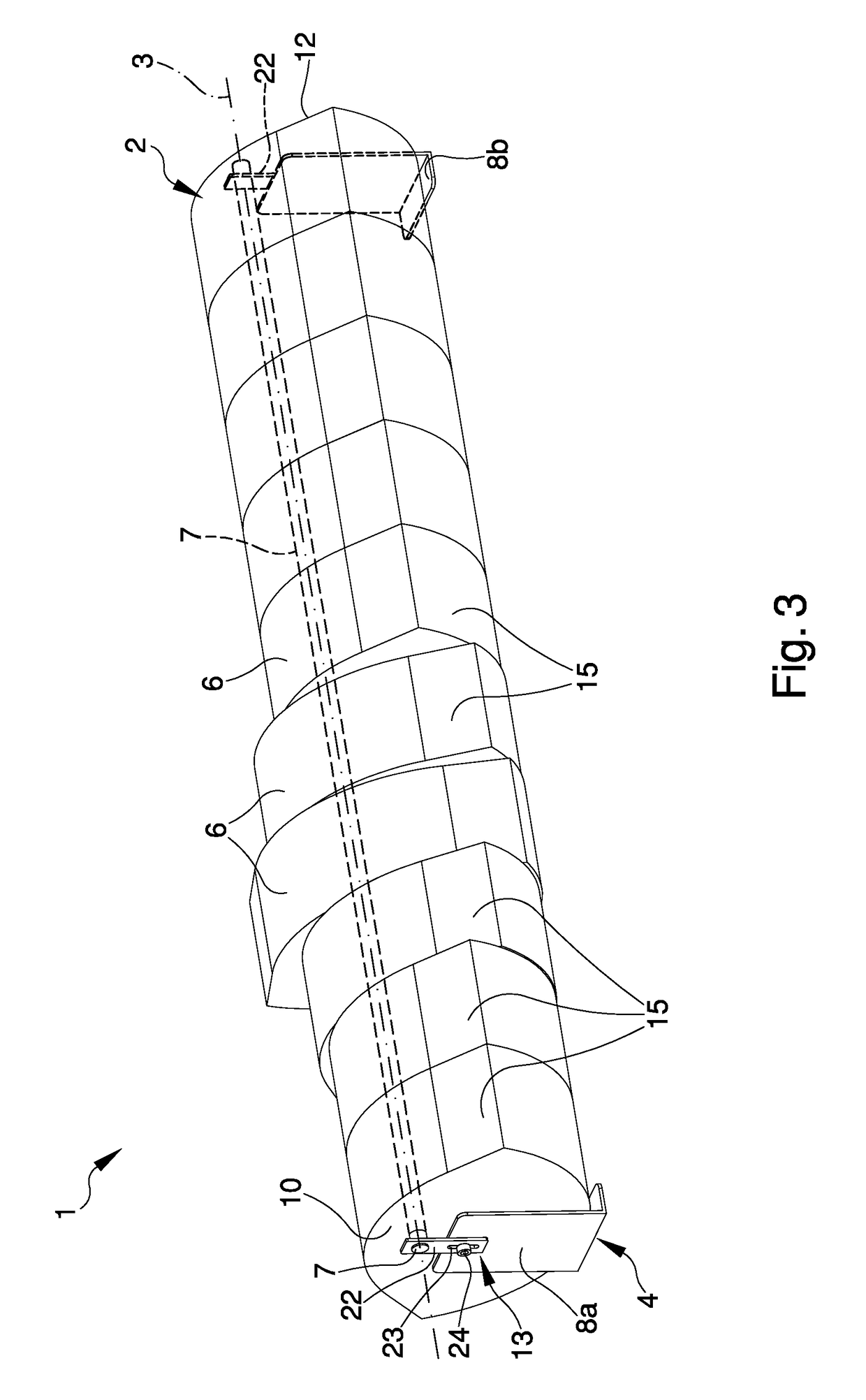

Bird deterrent

ActiveUS20170215406A1Effectively fixedImprove the level ofRoof coveringPasturing equipmentEngineeringMechanical engineering

Owner:DAMBRA DOMENICO

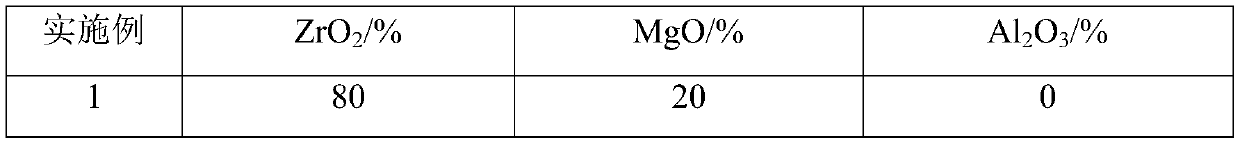

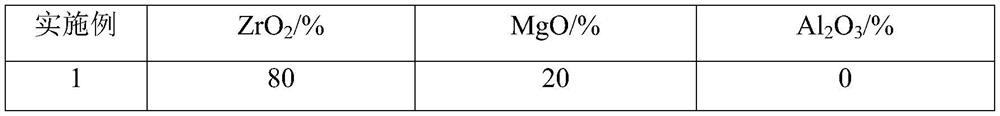

Anti-molten aluminum corrosion coating and preparation method thereof

ActiveCN110195228AHigh temperature wear resistanceAnti-stick to aluminumHot-dipping/immersion processesLiquid surface applicatorsAlloyThermal shock

The invention discloses an anti-molten aluminum corrosion coating. The coating is characterized by comprising at least three sub-coatings, namely the alloy layer arranged on the surface of a substratein a coating mode, a ceramic layer arranged on the surface of the alloy layer in a coating mode and a hole sealing layer arranged on the surface of the ceramic layer in a coating mode. The anti-molten aluminum corrosion coating has high-temperature abrasion resistance, aluminum sticking resistance, molten aluminum corrosion resistance, large bonding strength and excellent thermal shock resistance. Moreover, a preparation method of the anti-molten aluminum corrosion coating is easy to implement, coating materials are easy to obtain, and the production cost is reduced.

Owner:SHANGHAI JUSN SURFACE TECH ENG

Filter screen cleaning method

InactiveCN104841206AGood disinfection and sterilization effectEfficient removalFilter regenerationCleaning methodsImpurity

The invention relates to a filter screen cleaning method. The method comprises the following steps: 1, immersing a filter screen in an acidic solution with the pH value of 2-3 for a first predetermined time; 2, flushing the filter screen by using an alkaline solution with the pH value of 12-13 for a second predetermined time; 3, immersing the filter screen in the alkaline solution for a third predetermined time; and 4, flushing the filter screen by using a sodium hypochlorite-containing alkaline mixed solution with the pH value of 10-11. The method can effectively remove impurities on the filter screen in order to save the replacement cost of the filter screen.

Owner:SAE TECH DELEVOPMENT DONGGUAN

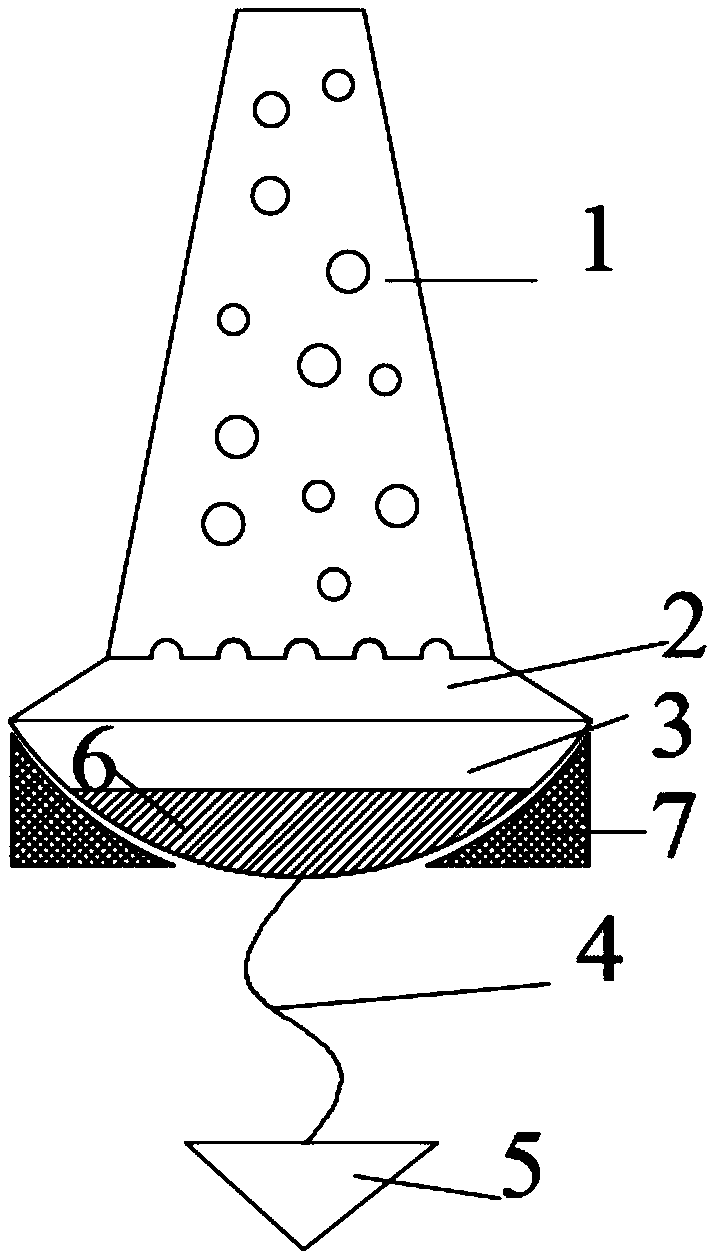

Flexible anti-glare device and mounting method thereof

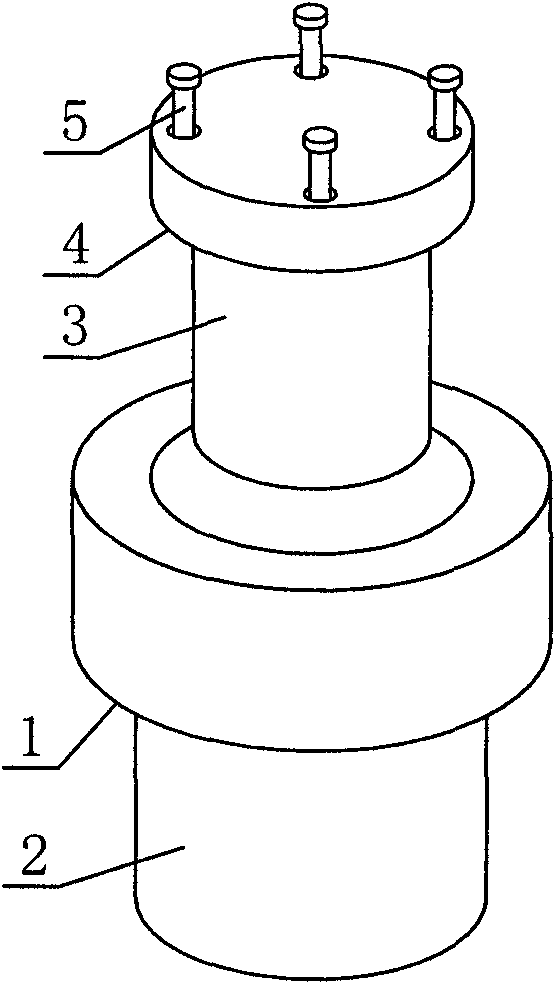

PendingCN108797406AReduce secondary damageReduce replacement and maintenance costsProtective constructionEngineeringStructural engineering

The invention discloses a flexible anti-glare device, and further comprises a mounting method thereof. The flexible anti-glare device comprises a cylinder, a transition round table, a base, a flexiblerope and a lead hammer. The transition round table is arranged at the bottom of the cylinder. The base is arranged at the bottom of the transition round table. The flexible rope is arranged at the bottom of the base. The lead hammer is suspended at the lower end of the base through the flexible rope. A ring of annular enclosure is arranged around the base, the height of the annular enclosure is less than that of the base, and the annular enclosure is used for ensuring that the anti-glare device does not offset under the normal situation. The flexible anti-glare device does not offset and tiltat the conventional wind speed, can topple and fall under severe weather such as a typhoon, and can also reset automatically after the typhoon.

Owner:JSTI GRP CO LTD +1

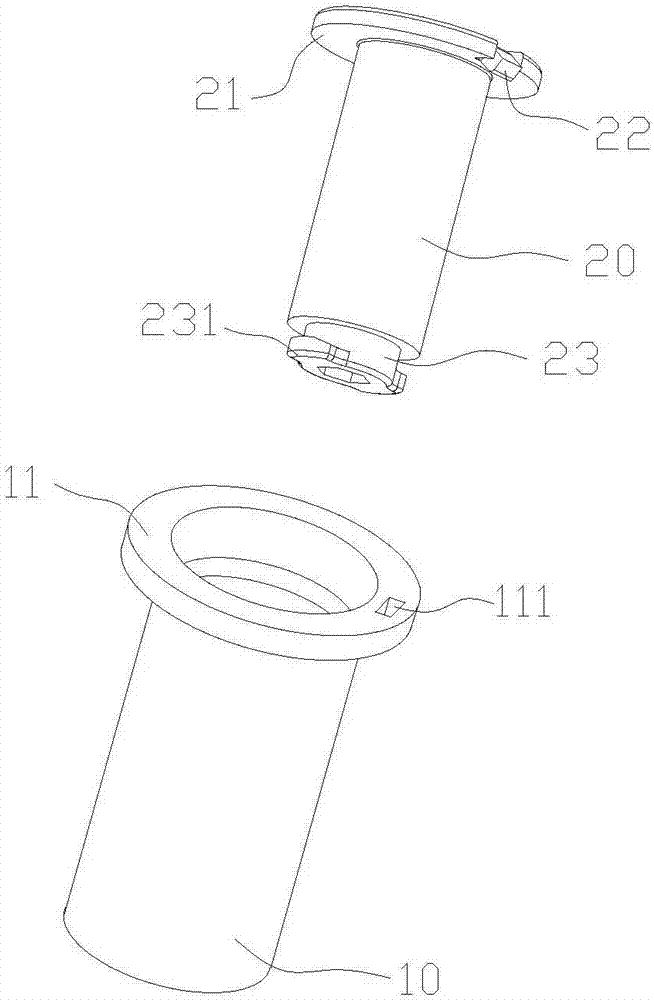

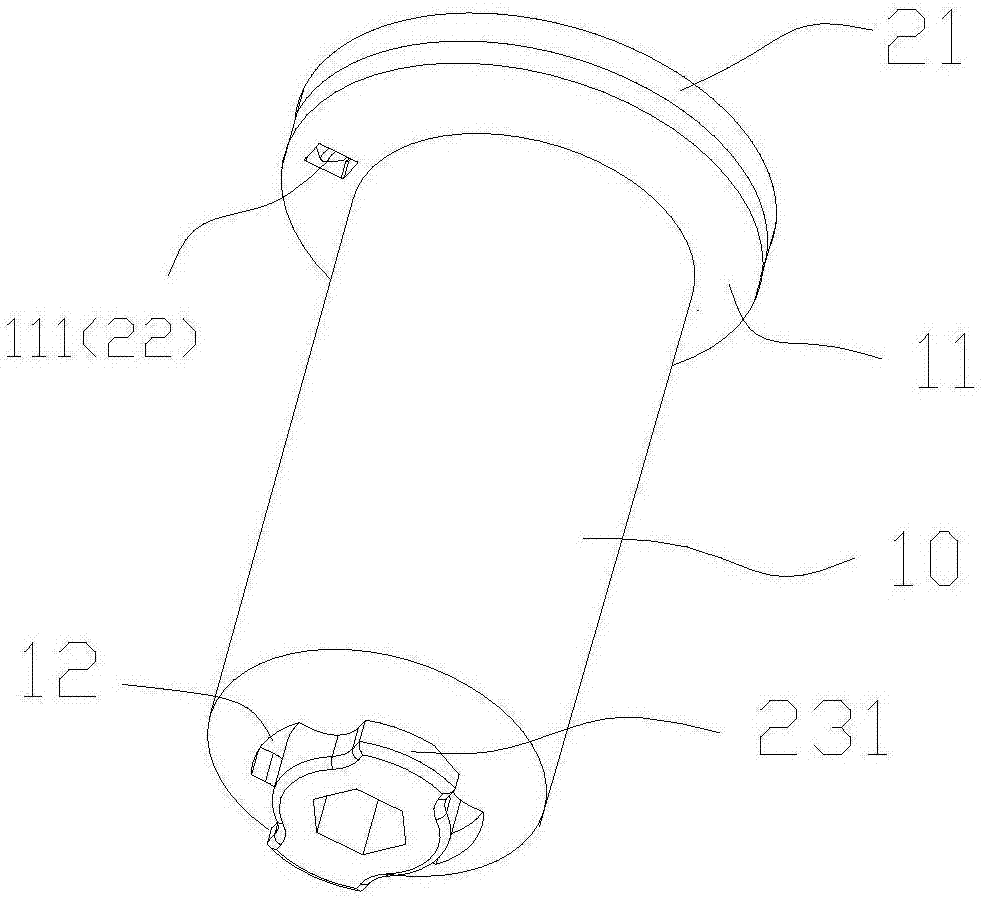

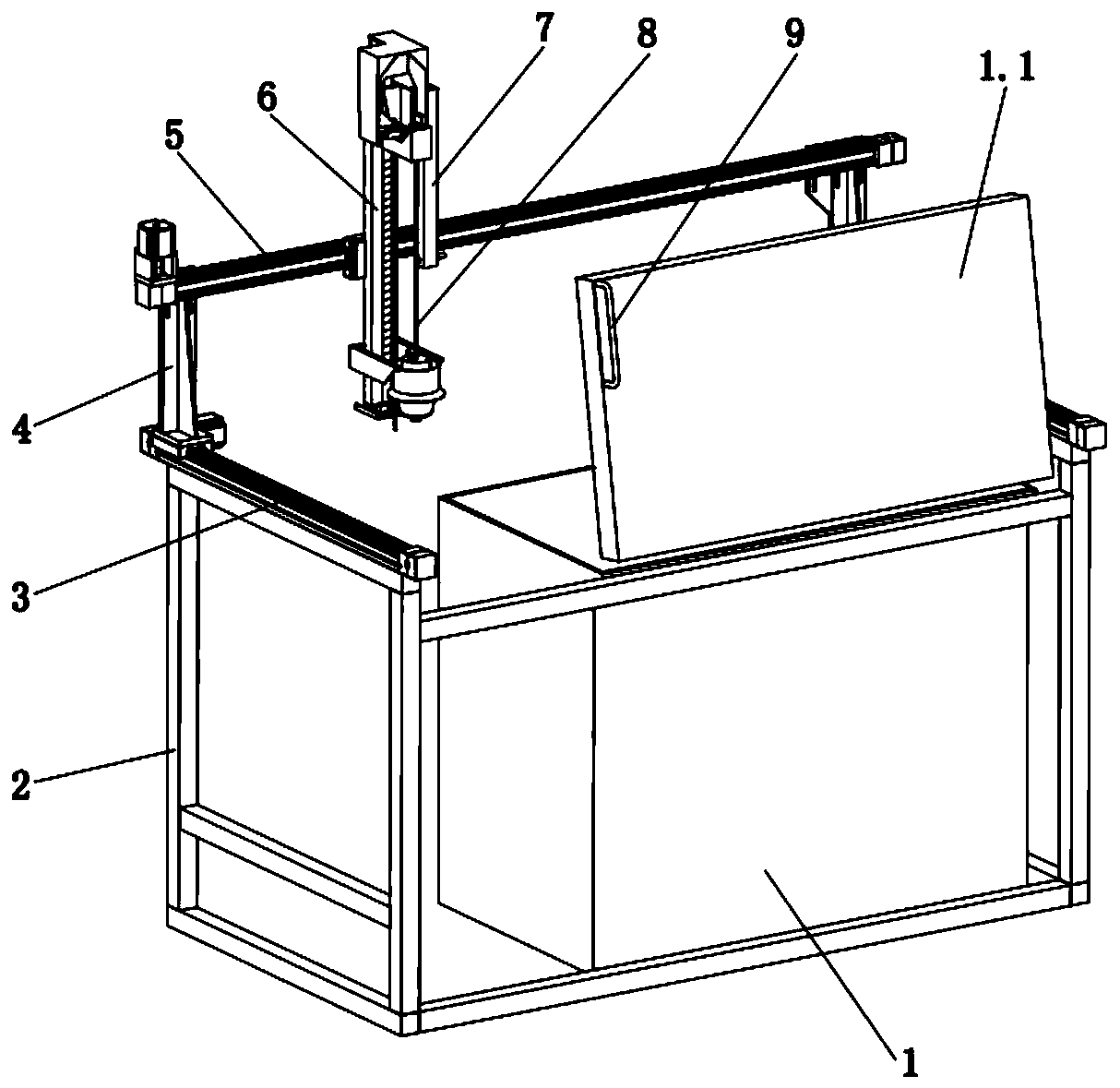

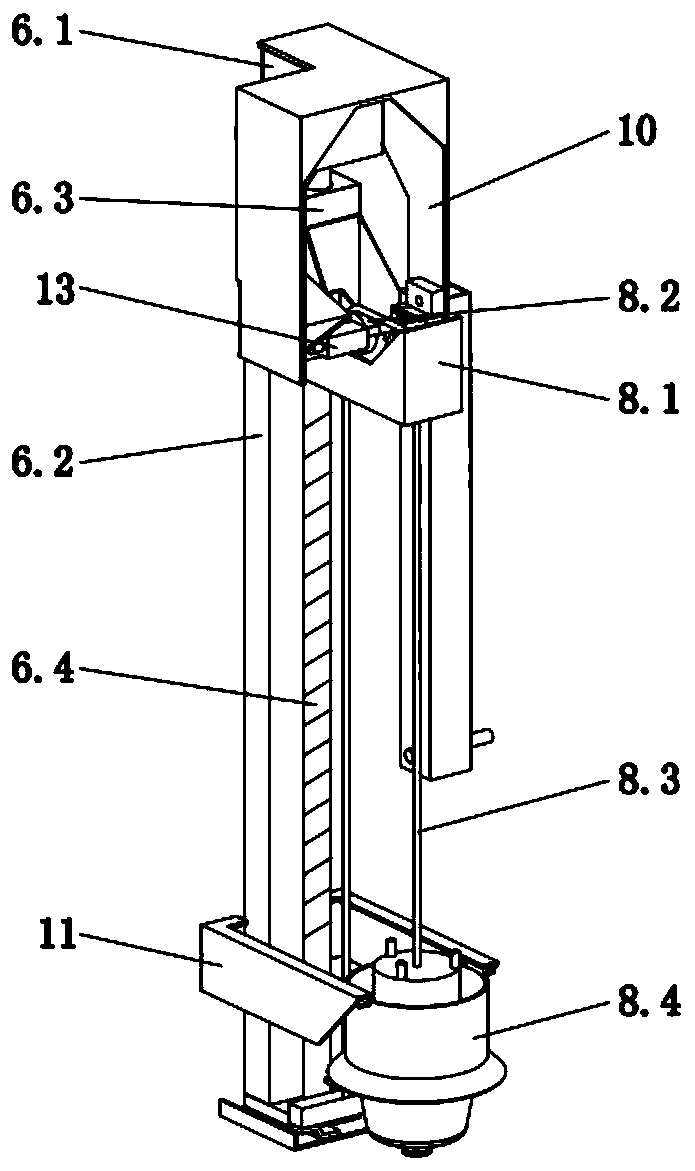

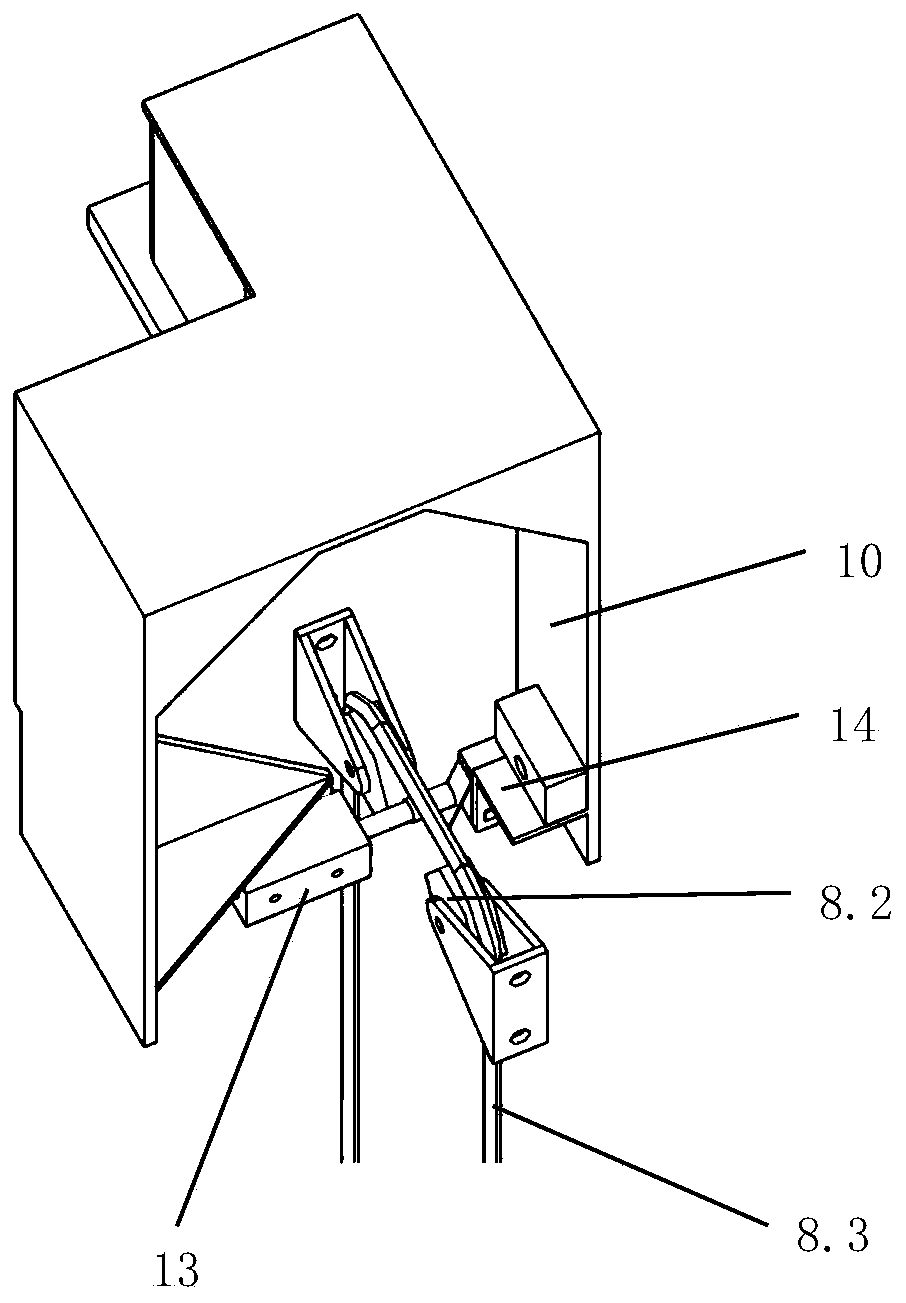

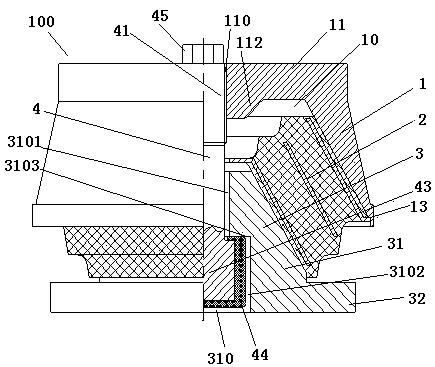

Doppler probe convent to assemble and disassemble

PendingCN107157514AEasy to install and removeReduce replacement and maintenance costsUltrasonic/sonic/infrasonic diagnosticsSurgeryPhysicsEngineering

The invention provides a Doppler probe convent to assemble and disassemble. The Doppler probe comprises a sleeve, wherein a probe body is arranged in a cavity of the sleeve, a flanging extending outwards is arranged at the end part of one end of the sleeve, a limiting part is arranged on the bottom, at the other end, of the sleeve, a clamping hole is formed in the flanging, one end of the probe body is provided with a round plate with the diameter greater than the diameter of the sleeve, the round plate is provided with clamping jaws, one end of the probe body extends into the sleeve and is matched with the limiting part for limiting the axial movement of the probe body, and the clamping jaws and the clamping hole are matched for limiting the circumferential rotation of the probe body. When the probe is mounted, one end of the probe body extends into the sleeve and is matched with the limiting part, thus the axial movement of the probe body is limited, the probe body is rotated to enable the clamping jaws of the round plate to be matched with the clamping hole, thus the circumferential rotation of the probe body is limited, the mounting of the probe is completed, therefore, the assembly and disassembly of the Doppler probe are greatly facilitated, and the replacement and maintenance costs are reduced.

Owner:SUZHOU L BIO BIOTECH

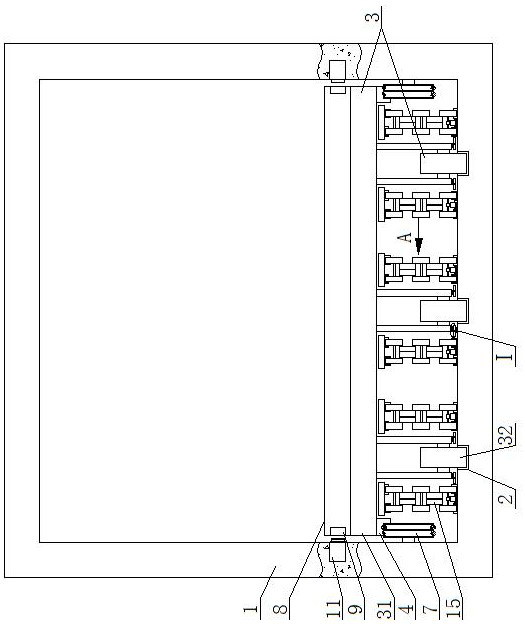

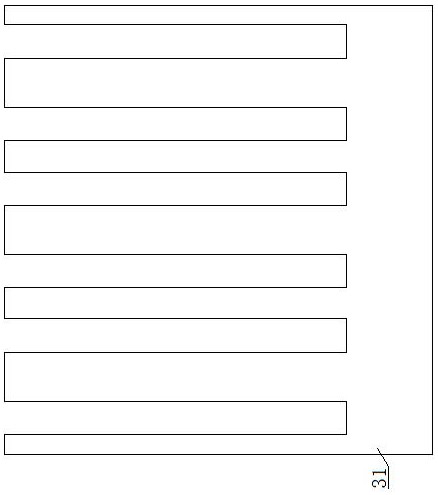

Rapid conveying device for building materials

InactiveCN114671204AMobile impactFree from loading and unloading workMechanical conveyorsArchitectural engineeringFire brick

A rapid conveying device for building materials comprises a hole body and a plurality of rails arranged at the bottom of the hole body, a plate trailer for going in and out of the hole body is arranged on the rails, the plate trailer is composed of a comb plate and a plurality of rows of moving wheels at the bottom of the comb plate, a plurality of protruding blocks are installed at the bottom of the comb plate, and the front face and the rear face of each protruding block are connected with one end of a steel cable. The other ends of the two steel cables connected with each protruding block are connected with the corresponding wire stranding wheels, the wire stranding wheels are connected with a power device, a supporting plate is movably installed on the top of the comb plate, switch valves are arranged on the first pipeline, the second pipeline and the third pipeline, wedge-shaped blocks are arranged at the movable ends of the fourth oil cylinders, and the wedge-shaped blocks face the directions of the adjacent rails. A second strip-shaped plate is installed at the top of the second shear fork rod, one-way swing pieces are arranged on the two sides of the moving wheel correspondingly, and the one-way swing pieces can be in sliding contact fit with the wedge-shaped blocks. The conveying device is used for conveying building materials such as fired bricks, at least half of loading and unloading work can be omitted, and the working efficiency is doubled.

Owner:URUMQI VOCATIONAL UNIV

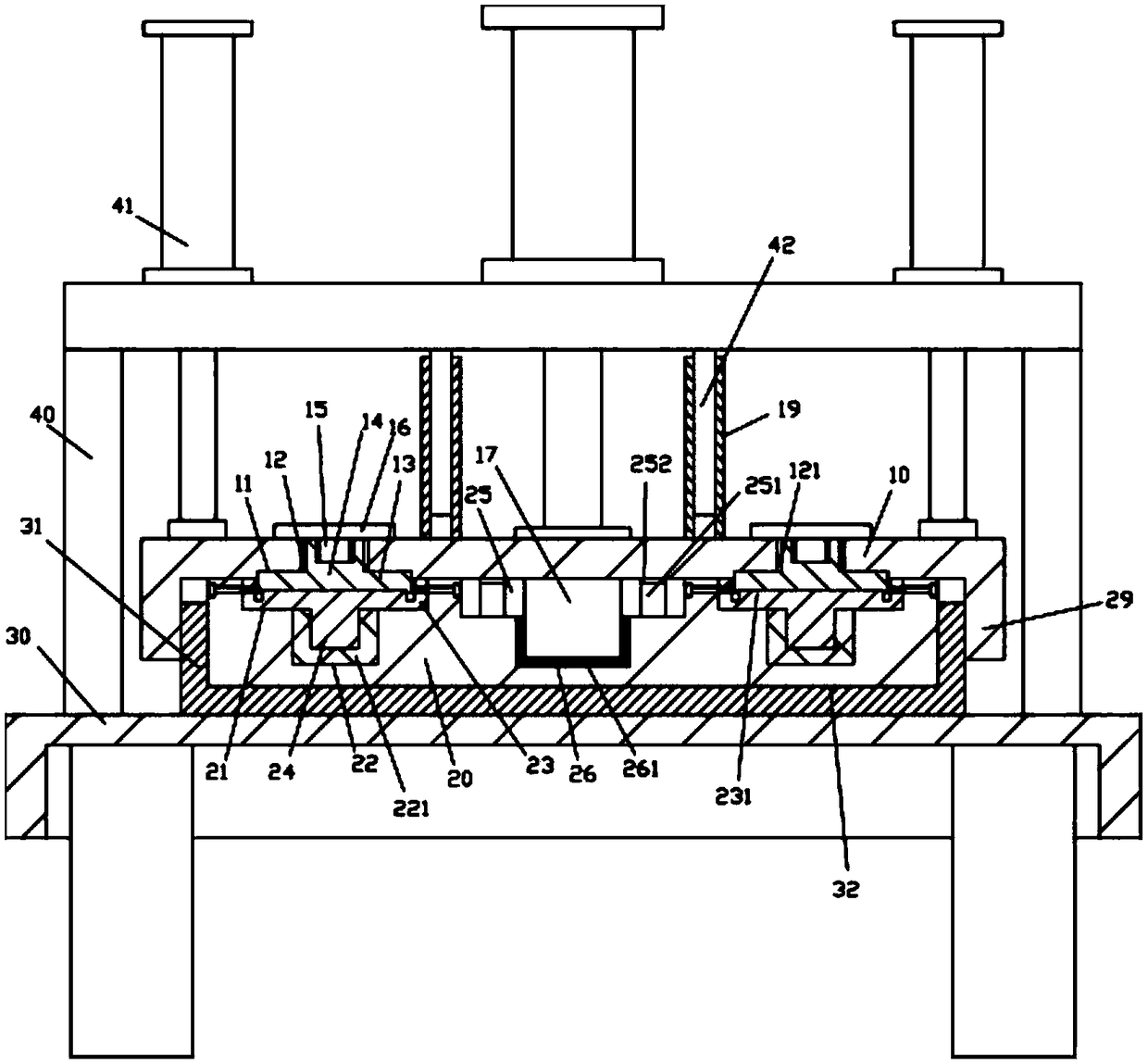

Punching mechanism adopting die with multiple form blocks

The invention discloses a punching mechanism adopting a die with multiple form blocks. The punching mechanism adopting the die with the multiple form blocks comprises a rack, an upper die installationblock and a lower die installation block, wherein an installation block is fixed to the top surface of the middle part of a top plate of the rack; a lower installation groove is formed in the middlepart of the top surface of the installation block; the lower die installation block is inserted and sleeved in the lower installation groove and is fixedly connected onto the bottom surface of the lower installation groove through a bolt; an upper support frame is fixed to the top surface of the top plate of the rack; multiple punching oil cylinders are fixed to the top surface of a top plate of the upper support frame; push rods of the punching oil cylinders penetrate through the bottom surface of the top plate of the upper support frame and are fixed onto the top surface of the upper die installation block; and two installation grooves are formed in the top surface of the lower die installation block. According to the punching mechanism provided by the invention, the multiple punching oil cylinders are adopted for punching, so that the forming stress is ensured to be uniform; meanwhile, multiple upper dies and lower dies are arranged on the upper die installation block and the lowerdie installation block, so that multiple products can be formed independently at one time; and when part of upper dies or lower dies are damaged, only the corresponding upper dies or lower dies need to be replaced.

Owner:DONGGUAN TIANHE ELECTROMECHANICAL DEV CO LTD

Selling commodity claiming mechanical hand

PendingCN111283665AAvoid injuryGuaranteed room for errorProgramme-controlled manipulatorGripping headsRobot handElectric machinery

The invention discloses a selling commodity claiming mechanical hand. A motor is in driving connection with a nut block. The nut block is provided with a pair of rollers and a door opener. The rollerslift a suction cup through a winding rope. The rollers and the rope are arranged in a clutch mode. The nut block is integrally provided with the door opener and the rollers and suction cup lifted through the winding rope, so that the mechanical hand can have the functions of opening and closing a door and the function of grabbing, and the commodity selling claiming process can be achieved just through one set of the structure. The motion type door opening and closing process has the advantages that the stability is good, the opening and closing degree of cabinet doors is adjustable, the replacement and maintenance cost is low, the adjusting process difficulty is low, meanwhile, the three-dimensional movable grabbing mechanism replaces the motor to drive a commodity pushing mechanism to push out commodity bar structures, the process of grabbing commodities by imitating human hands is achieved, multiple motors do not need to be arranged, commodities cannot cause friction with a bar channel, and the commodities are protected against injuries so that the commodity integrity can be ensured.

Owner:青岛诺金自动化装备有限公司

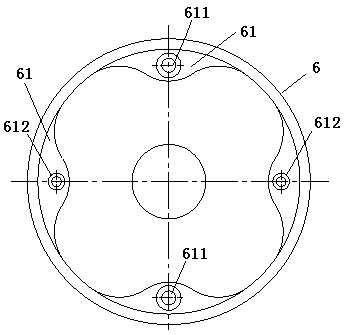

Bird deterrent

ActiveUS9924707B2Effectively fixedImprove the level ofRoof coveringAnimal repellantsEngineeringMechanical engineering

Owner:DAMBRA DOMENICO

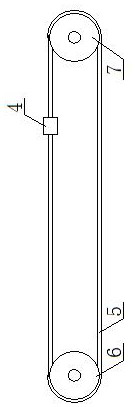

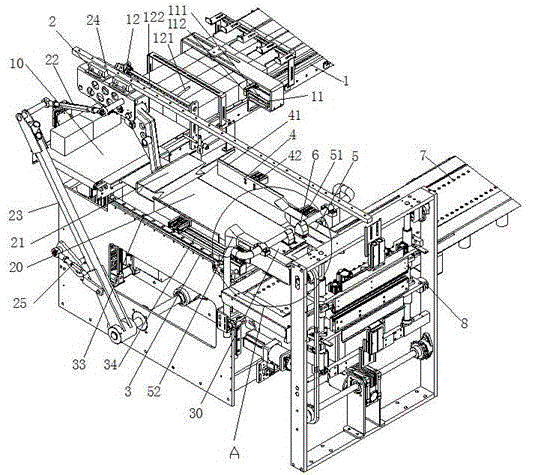

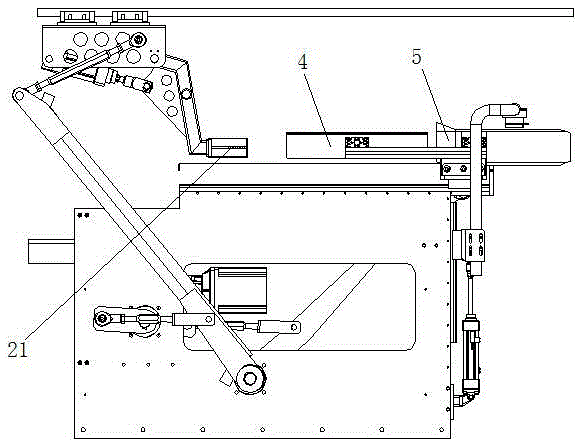

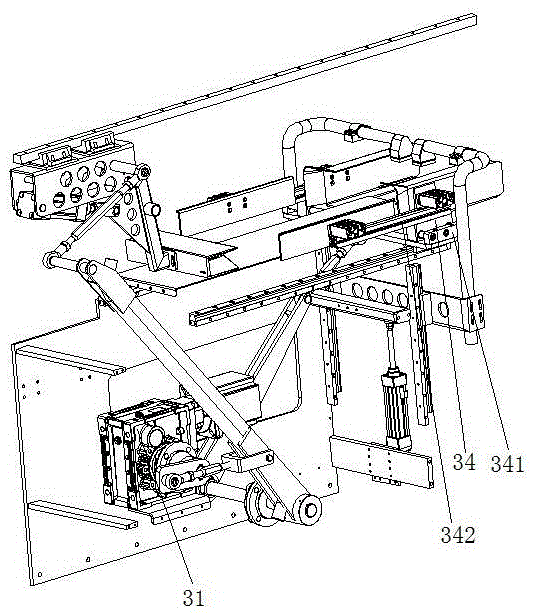

Material holding and conveying device of prefabricated bag packaging machine

ActiveCN105667882AImprove delivery efficiencyShorten holding strokePackagingEngineeringReciprocating motion

The invention discloses a material holding and conveying device of a prefabricated bag packaging machine, and belongs to the technical field of packaging machines. The material holding and conveying device is characterized by comprising a horizontal moving mechanism and a holding mechanism connected with the horizontal moving mechanism; the holding mechanism does the reciprocating motion in the material running direction under the effect of the horizontal moving mechanism. Materials cannot be shaken in the conveying process, and material conveying is more stable compared with that of a clamping mechanism, the materials cannot be clamped and extruded, and the material conveying efficiency is improved; and the holding mechanism does the reciprocating motion in the material running direction under the effect of the horizontal moving mechanism, material conveying and holding are independently matched, the whole holding stroke is shortened, and the follow-up prefabricated bag packaging efficiency can be further improved.

Owner:上海松川峰冠包装自动化有限公司

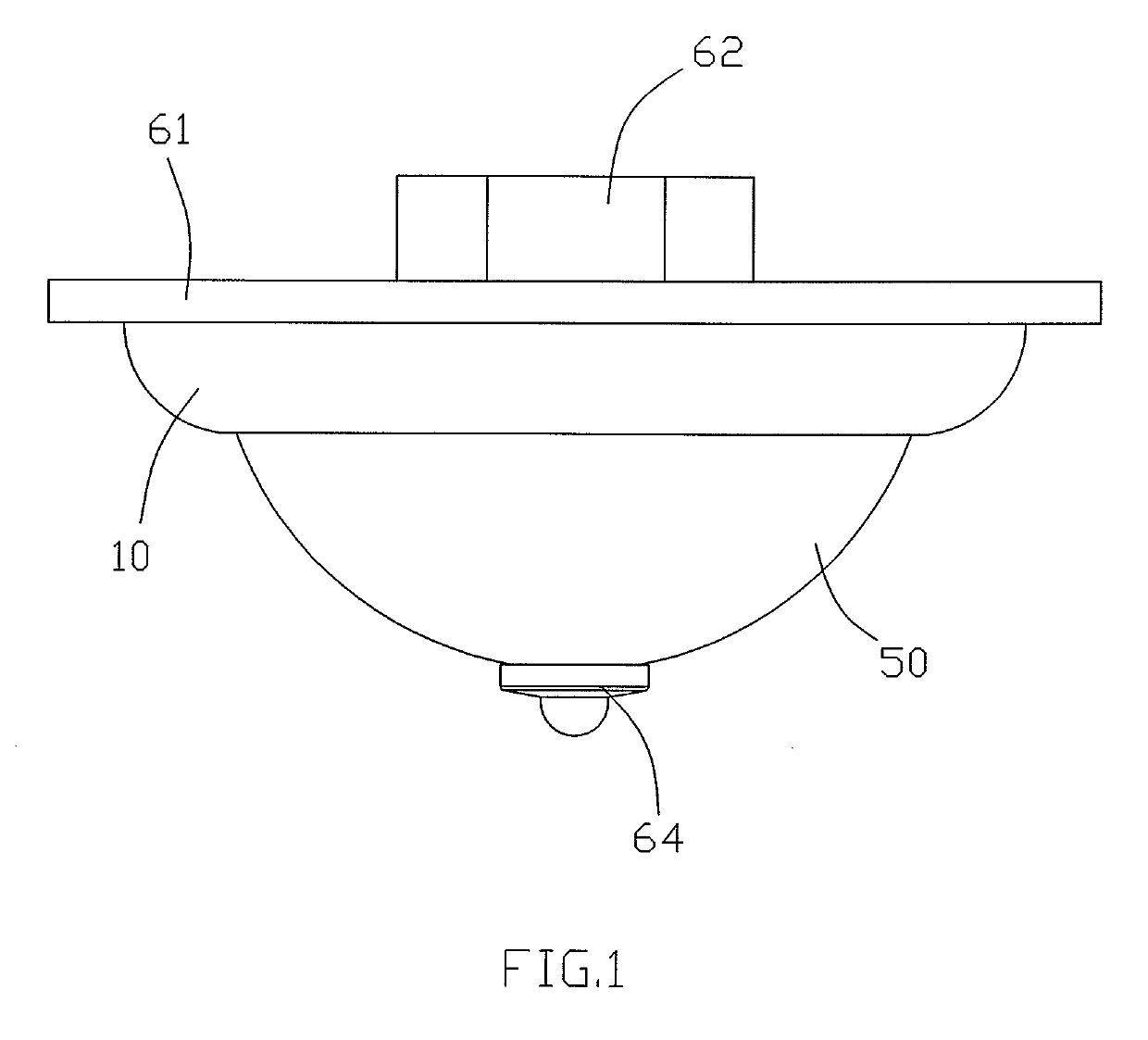

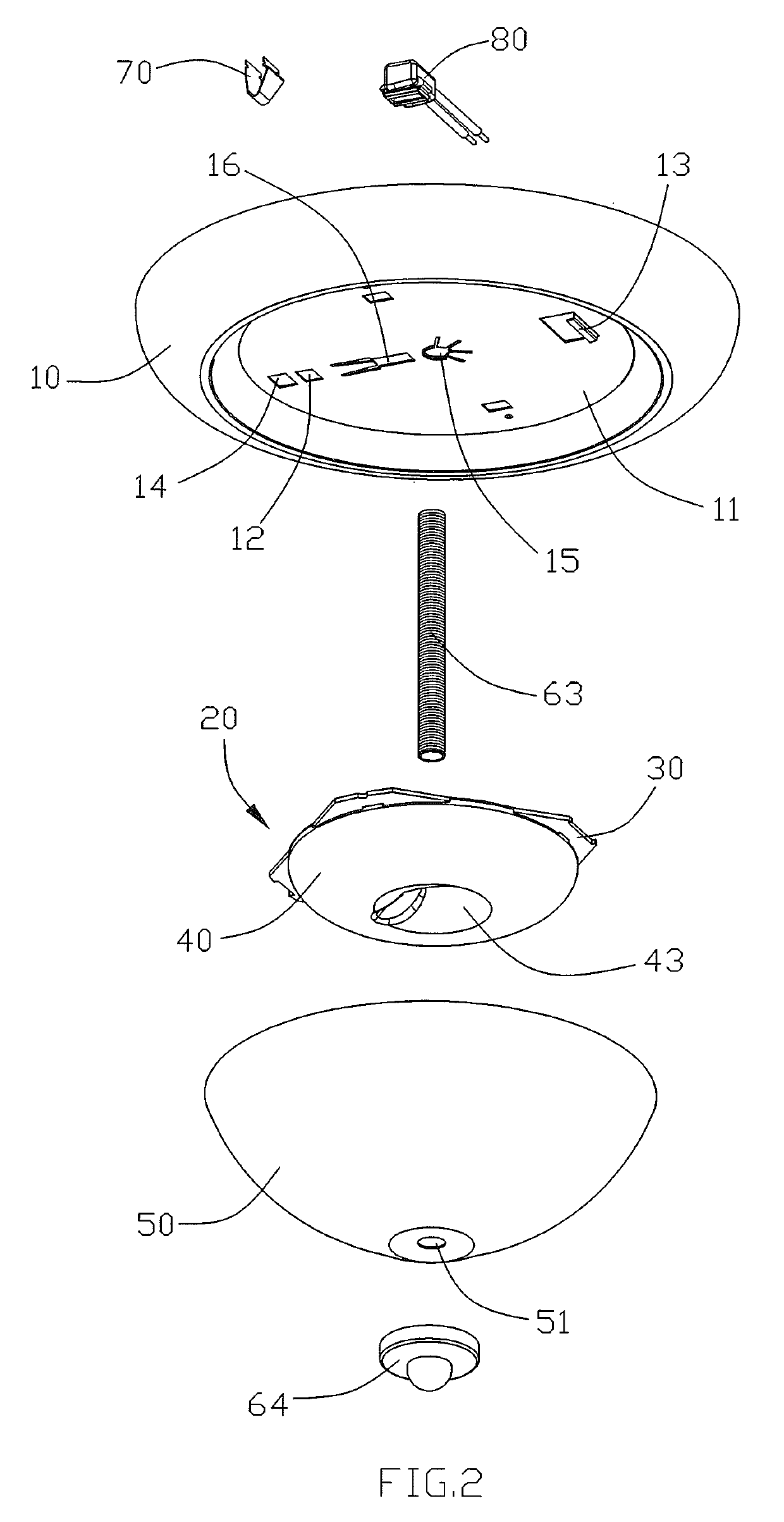

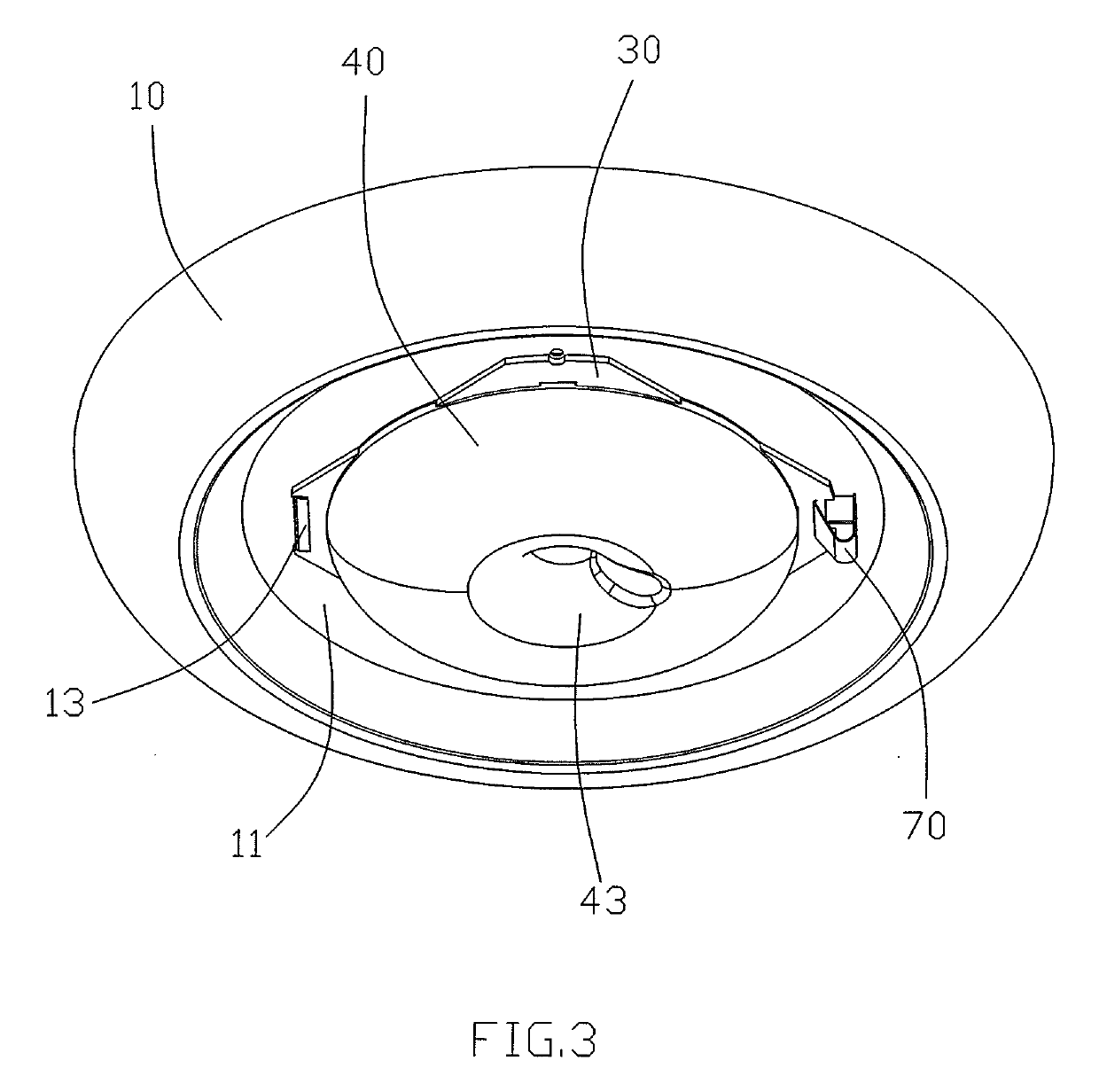

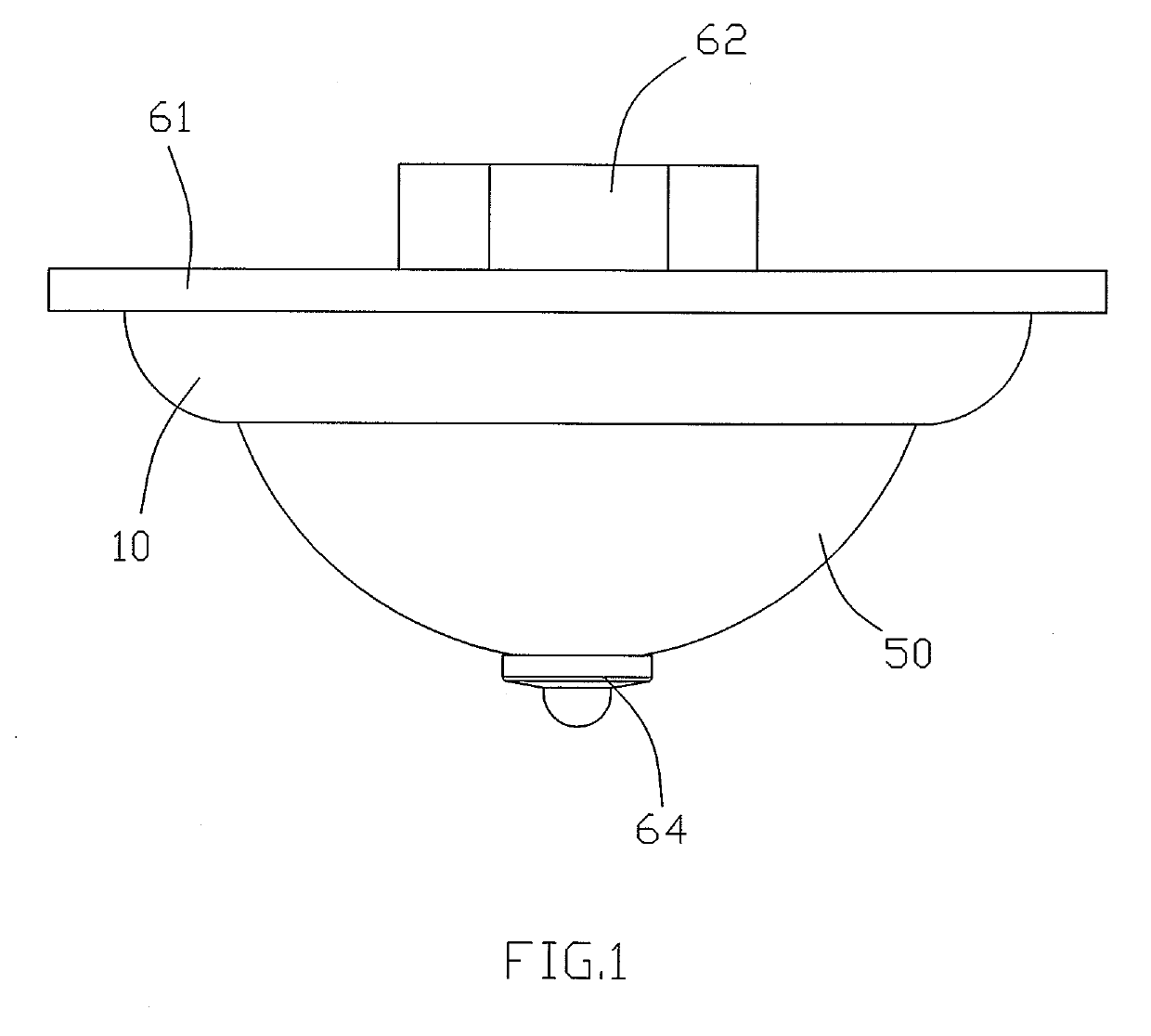

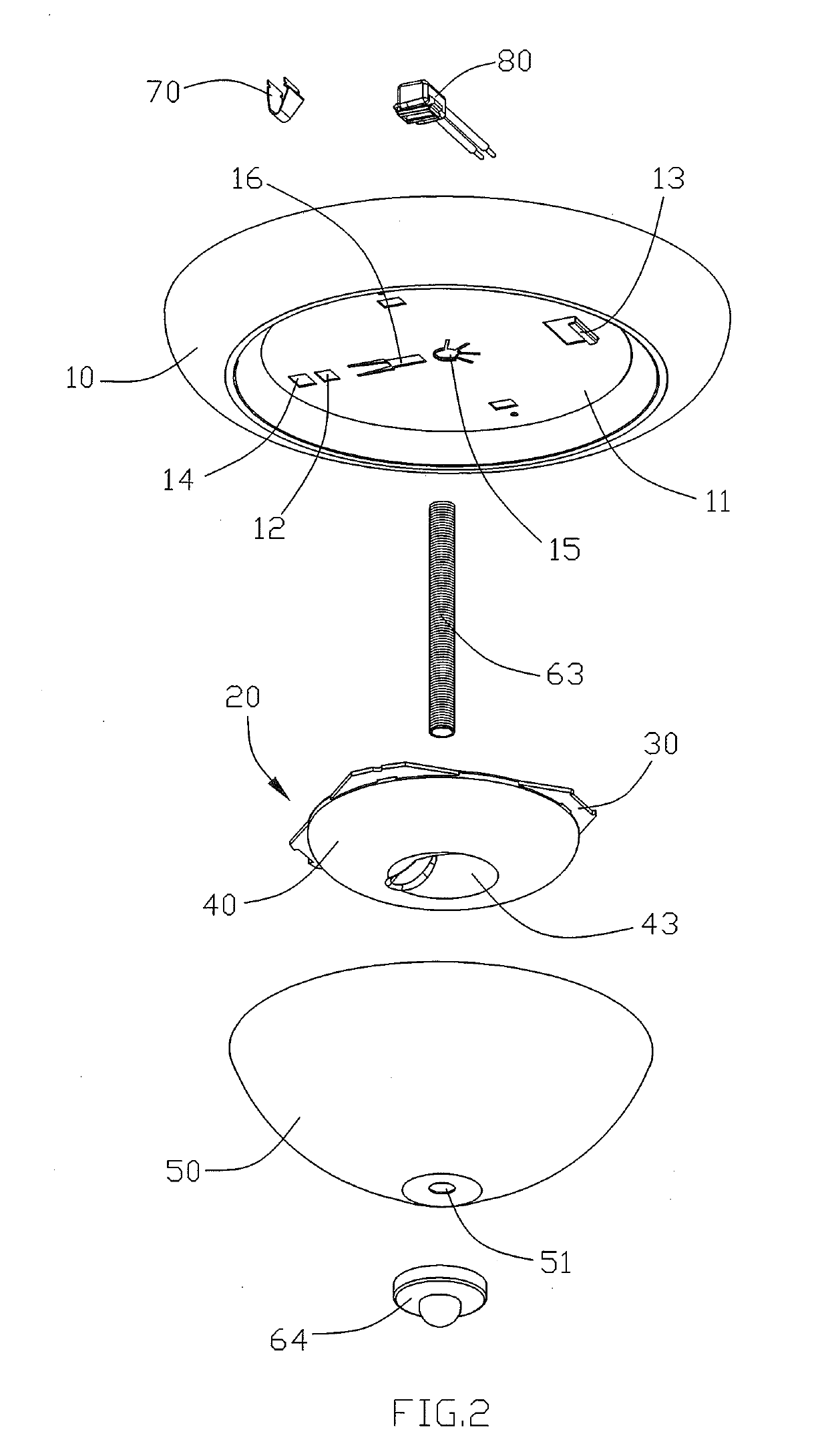

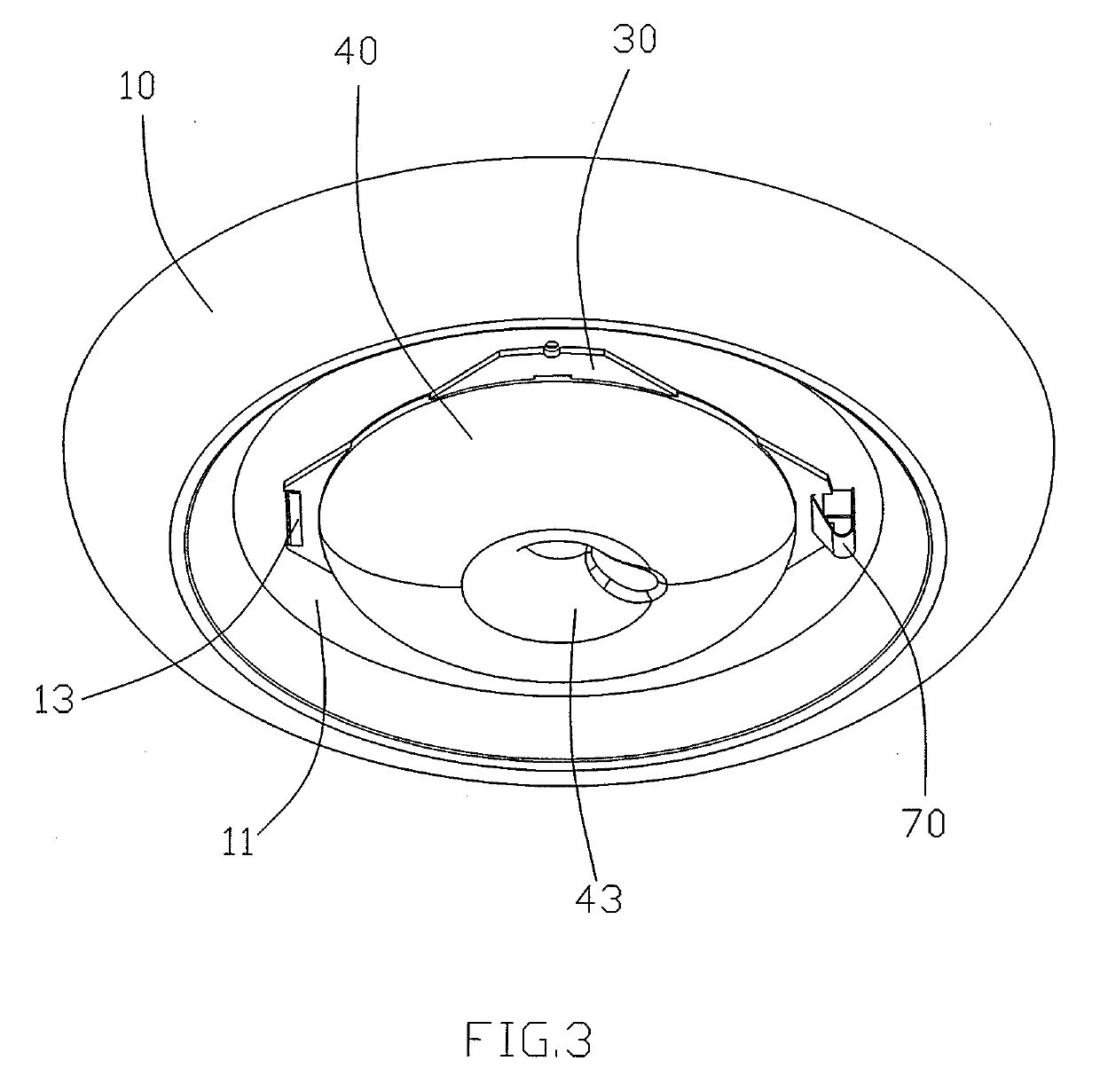

Ceiling fitting with a lighting module

ActiveUS10408438B2Reduce replacement and maintenance costsEasy to disassembleElectrically conductive connectionsLighting support devicesEffect lightEngineering

A ceiling fitting includes a canopy provided with a fixed hook and a mounting hole, a movable hook mounted on the mounting hole of the canopy and having an arcuate restriction portion, a lighting module removably mounted on the canopy, and an outer cover covering the lighting module. The lighting module includes a lamp board mounted on the canopy and located between the movable hook and the fixed hook, and a light permeable shell mounted on the lamp board. The lamp board is provided with a first retaining groove and a second retaining groove. The first retaining groove is locked onto the movable hook, with the restriction portion of the movable hook being retained by the first retaining groove of the lamp board. The second retaining groove is locked onto the fixed hook.

Owner:DONG GUAN BRIGHT YIN HUEY LIGHTING

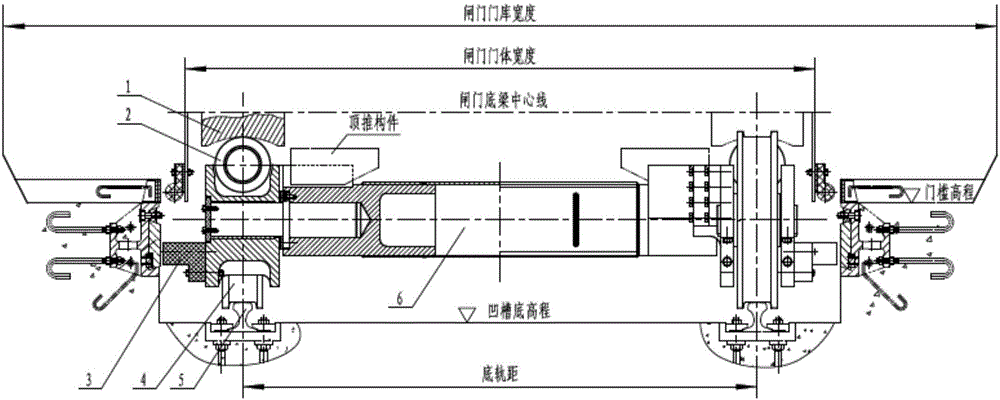

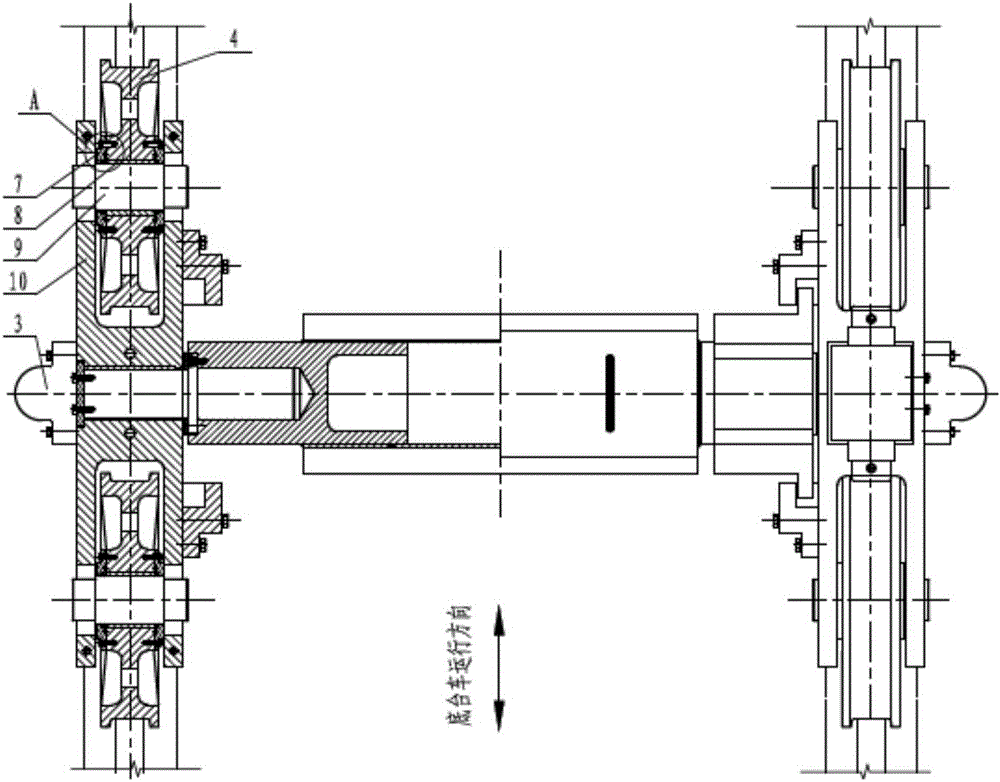

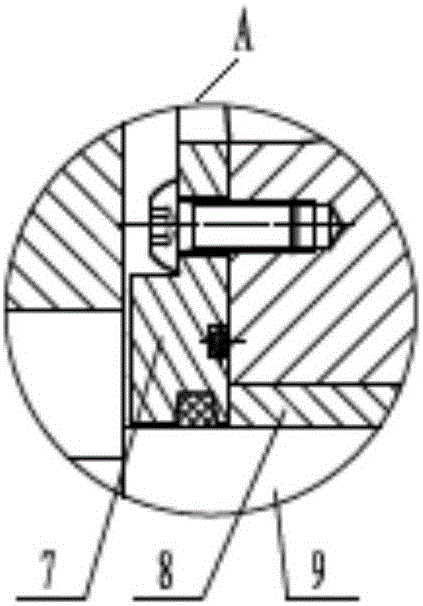

Horizontal pulled gate bottom trolley with rolling wheels of self-lubricating bearing structure

The invention discloses a horizontal pulled gate bottom trolley with rolling wheels of a self-lubricating bearing structure. Every two sets of rolling wheel parts are installed on a frame; the left frame and the right frame are connected into an overall framework of the bottom trolley through a frame beam; a gate body is located on roller parts of the bottom trolley through arc-shaped base plates; the roller parts transversely move under water pressure to complete attaching leaning and water stoppage; the left rolling wheel parts and the right rolling wheel parts travel along bottom rails laid in a groove lower than a doorsill in parallel so that the gate body can travel forwards and backwards along the bottom rails to be opened and closed; the four sets of rolling wheel parts are of the same structure; each rolling wheel part comprises a rolling wheel, a rolling wheel shaft, a self-lubricating bearing and self-lubricating bearing sealing covers; the rolling wheels are installed on the frames through the rolling wheel shafts; the self-lubricating bearings are arranged between the rolling wheels and the rolling wheel shafts; and the two ends of each self-lubricating bearing are sealed through the corresponding self-lubricating bearing sealing covers. The structure is simple, the manufacturing cost is reduced, the horizontal pulled gate bottom trolley is easy to maintain and even is free of maintenance, and the defects of underwater use of roller bearings in the prior art can be totally overcome.

Owner:JIANGSU PROVINCIAL COMM PLANNING & DESIGN INST

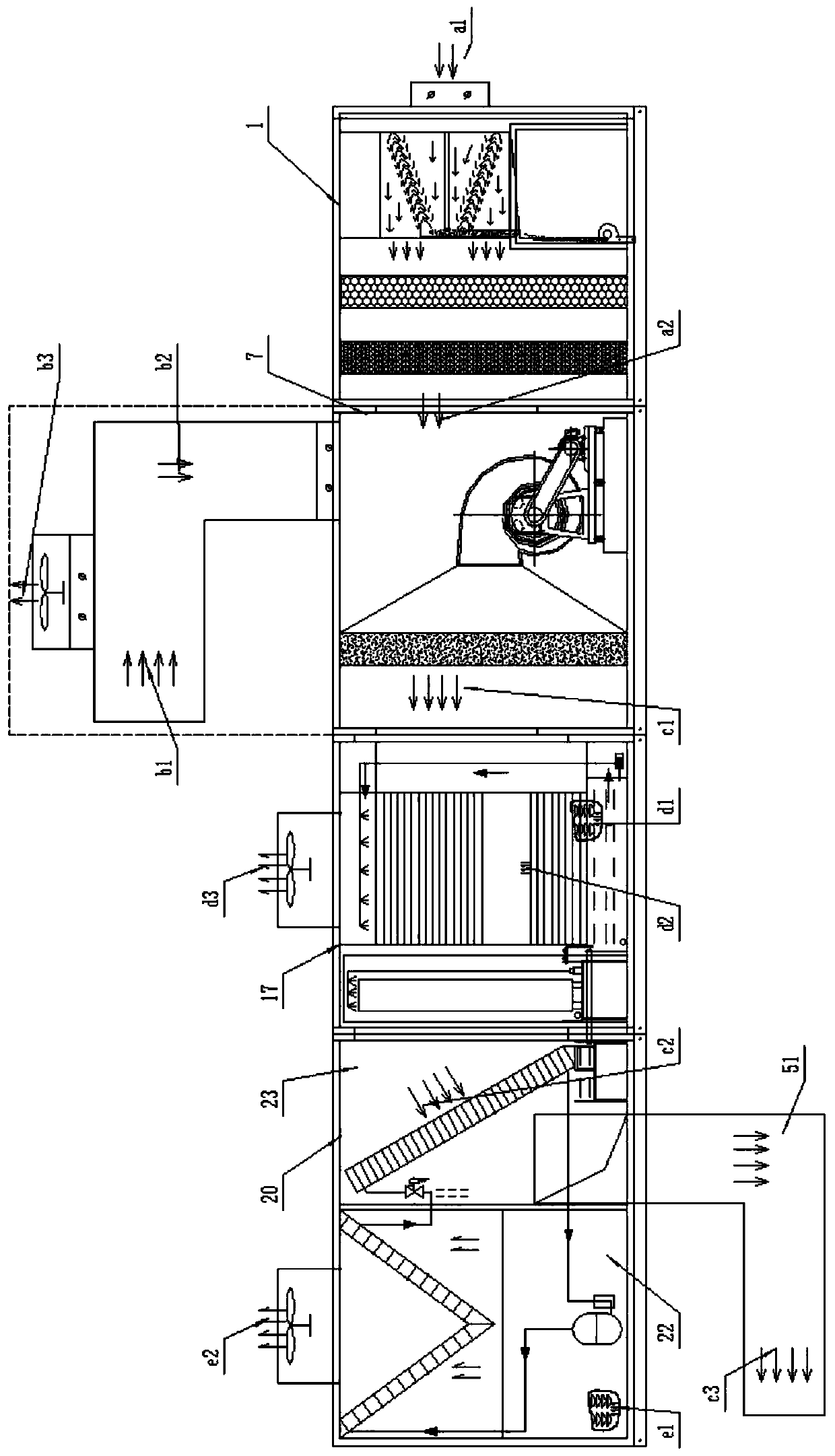

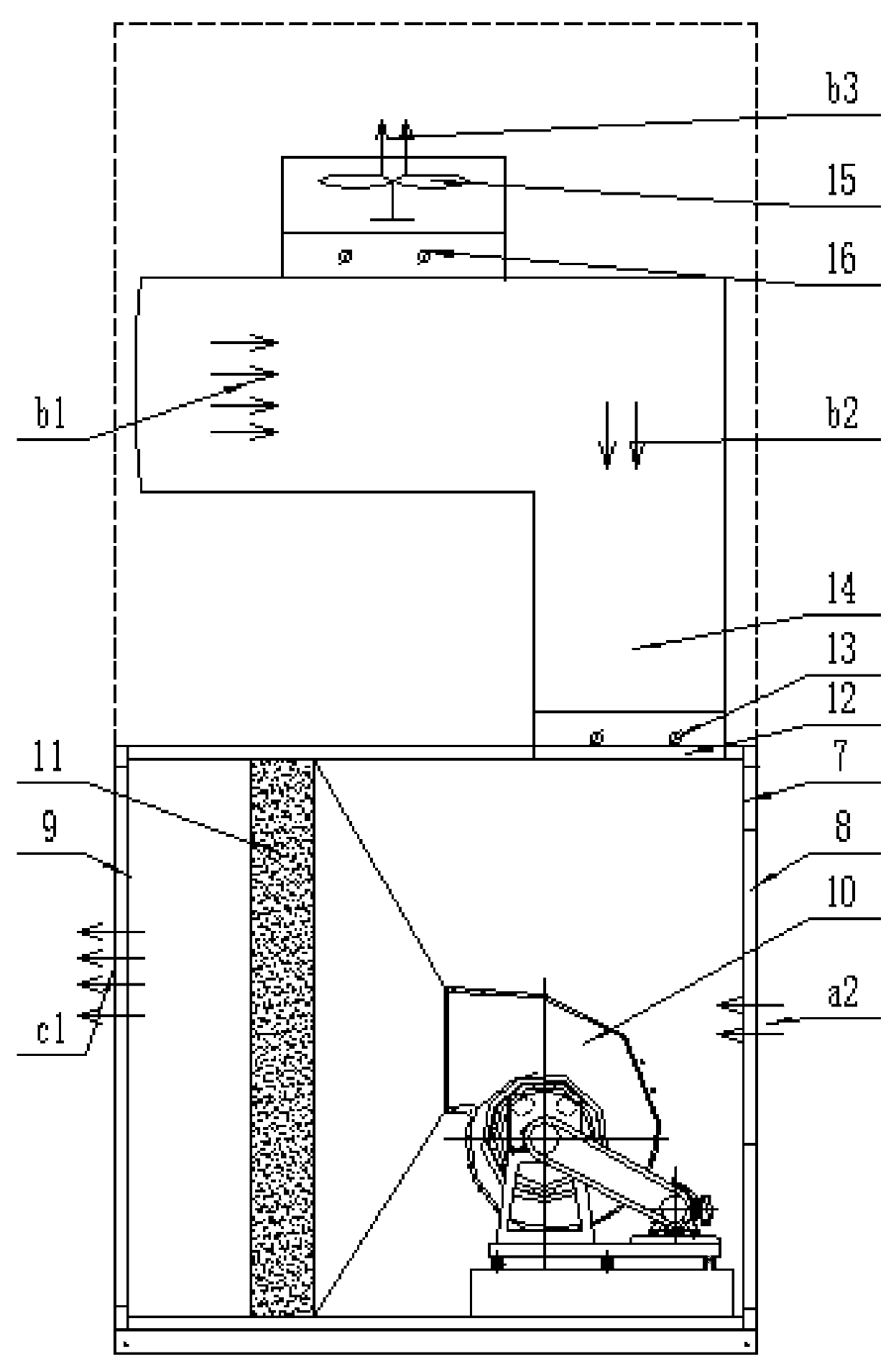

Modular double-cooling source data center cooling system combined with fresh air

PendingCN110671754AReduce replacement and maintenance costsAvoid refrigerationMechanical apparatusLighting and heating apparatusFresh airProcess engineering

The invention discloses a modular double-cooling source data center cooling system combined with fresh air. The system comprises a fresh air treatment section module, an air mixing section module, a water evaporation refrigeration section module and a mechanical refrigeration section module. The system has the outstanding advantages of convenient assembly, small maintenance amount, high reliability, low energy consumption and the like, realizes the micro-positive pressure of the protection space on the basis of ensuring the clean and tidy data center environment, can automatically adjust the configuration of cold sources according to the actual condition of the natural environment, and realizes the maximization of energy conservation.

Owner:上海震业环境科技有限公司

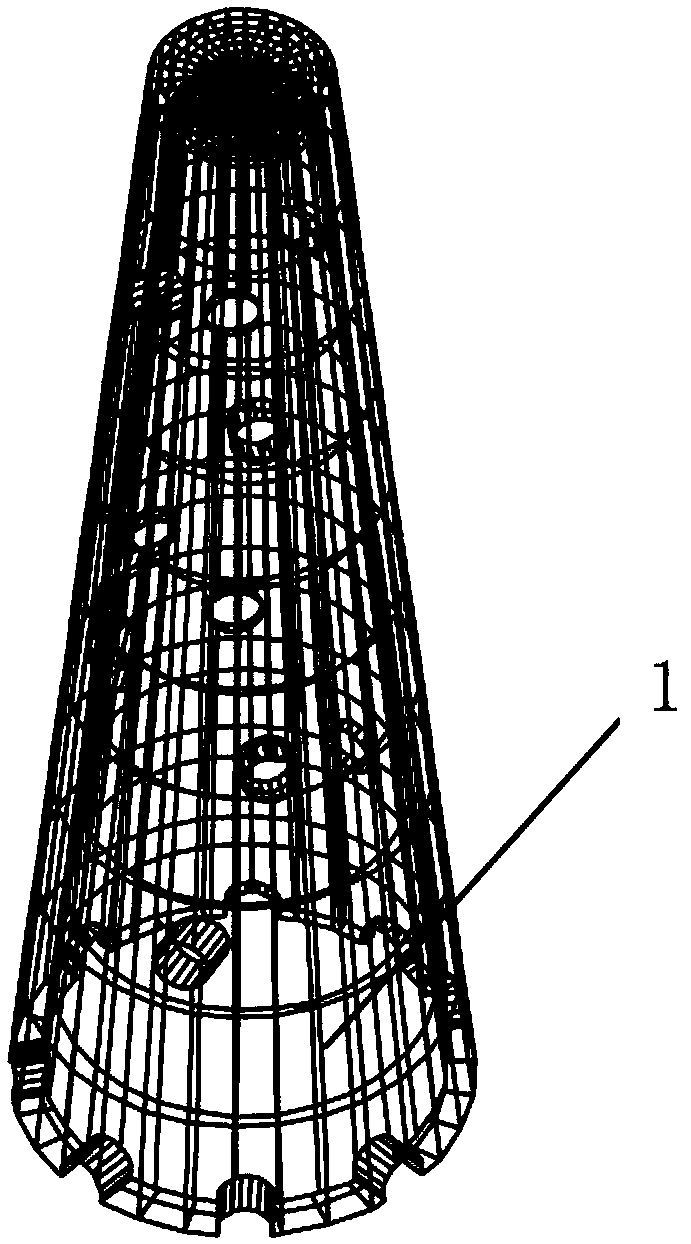

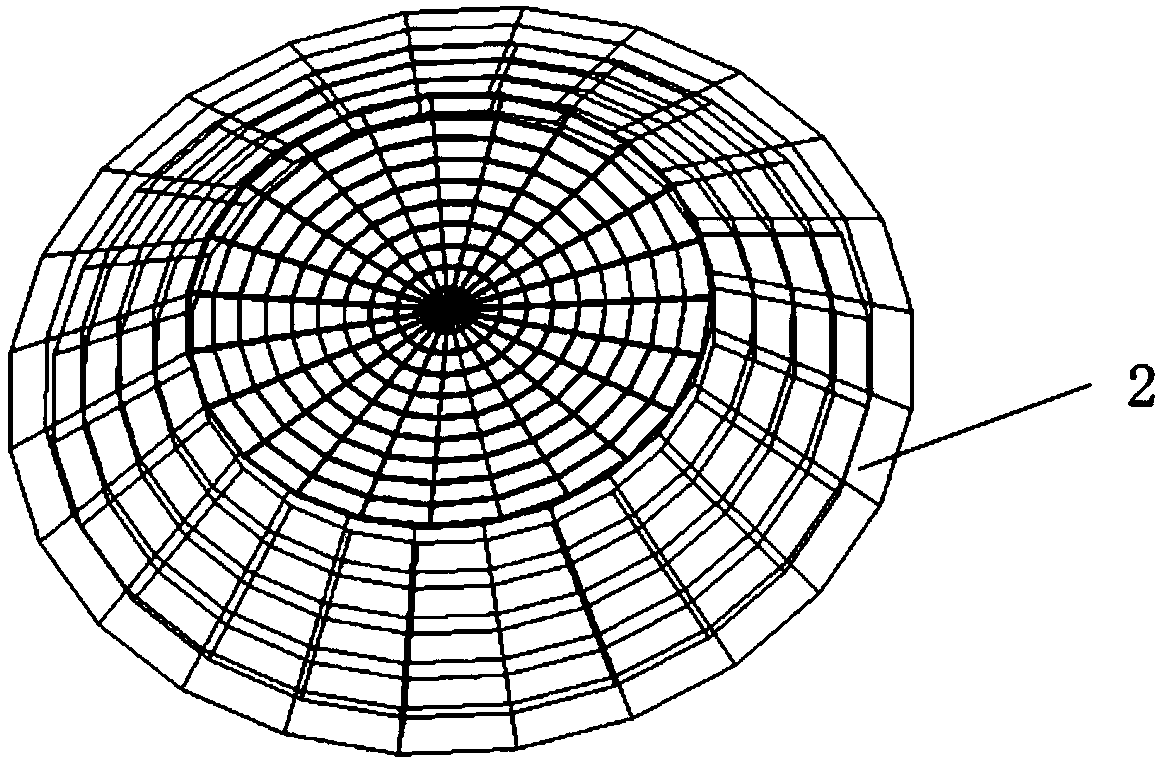

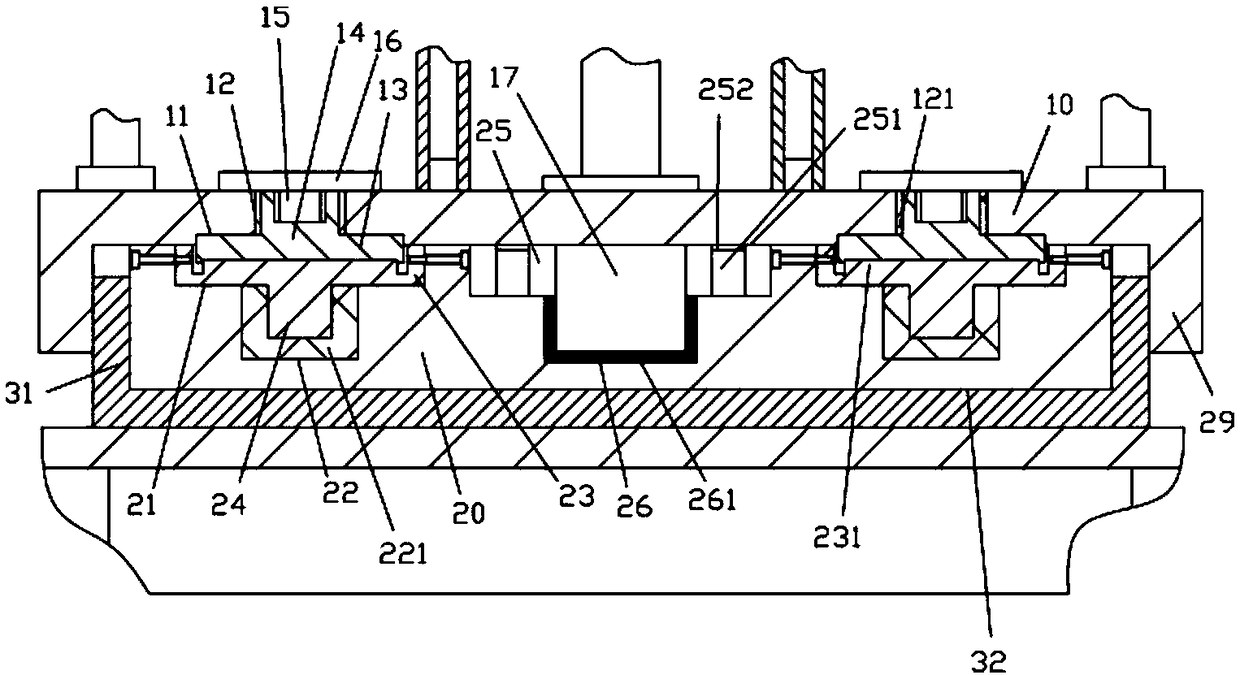

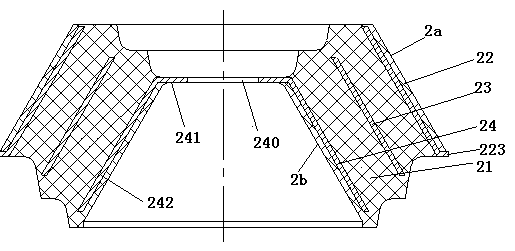

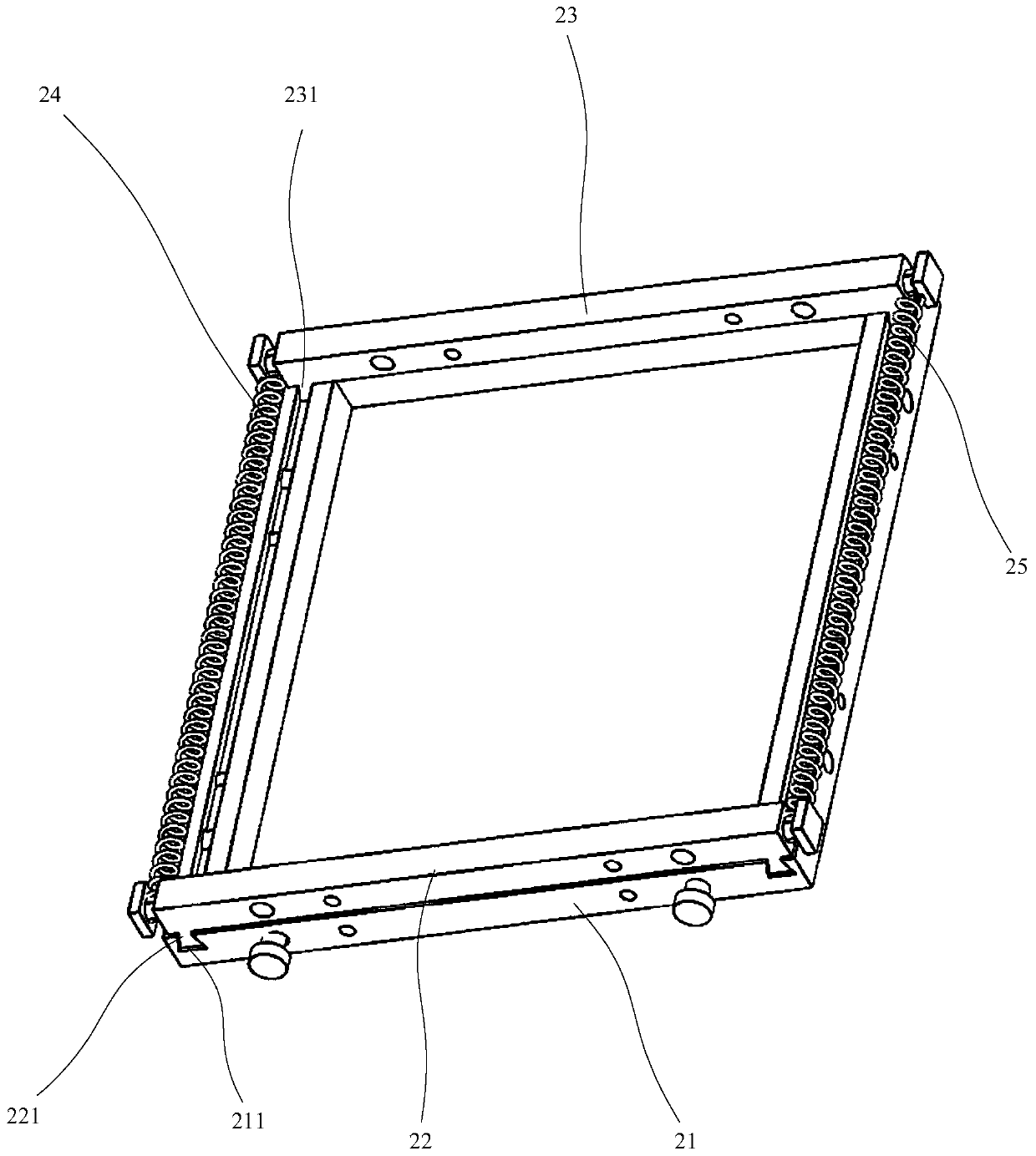

Combined rubber vibration isolator for floating slab track

PendingCN108824102AMaintain vibration damping performanceAchieve regulationRailway tracksEngineeringMechanical engineering

The invention discloses a combined rubber vibration isolator for a floating slab track. The vibration isolator is composed of an upper metal piece, a rubber elastic piece, a lower metal piece and a locking component. The rubber elastic piece has the conical outer circumferential face and the conical inner circumferential face, and the outer circumferential face and the inner circumferential face of the rubber elastic piece are tightly attached to the upper metal piece and the lower metal piece respectively; the rubber elastic piece comprises a rubber piece body, an outer ring skeleton, a middle ring skeleton and an inner ring skeleton; the outer ring skeleton, the middle ring skeleton and the inner ring skeleton are arranged inside the rubber piece body separately and vulcanized with the rubber piece body into a whole. The locking component sequentially penetrates through the lower metal piece, the rubber elastic piece and the upper metal piece from bottom to top, the upper portion ofthe locking component is in spiral connection with the upper metal piece, and the lower portion of the locking component abuts against the lower metal piece. The invention further discloses an installing method of the combined rubber vibration isolator for the floating slab track. The vibration isolator is simple in structure, easy to disassemble, assemble, replace and maintain, and low in maintain cost.

Owner:NO 711 RES INST CHINA SHIPPING HEAVY IND GRP +1

Ceiling fitting with a lighting module

ActiveUS20190242559A1Reduce maintenance costsReduce replacement costsElectrically conductive connectionsLighting support devicesEngineering

A ceiling fitting includes a canopy provided with a fixed hook and a mounting hole, a movable hook mounted on the mounting hole of the canopy and having an arcuate restriction portion, a lighting module removably mounted on the canopy, and an outer cover covering the lighting module. The lighting module includes a lamp board mounted on the canopy and located between the movable hook and the fixed hook, and a light permeable shell mounted on the lamp board. The lamp board is provided with a first retaining groove and a second retaining groove. The first retaining groove is locked onto the movable hook, with the restriction portion of the movable hook being retained by the first retaining groove of the lamp board. The second retaining groove is locked onto the fixed hook.

Owner:DONG GUAN BRIGHT YIN HUEY LIGHTING

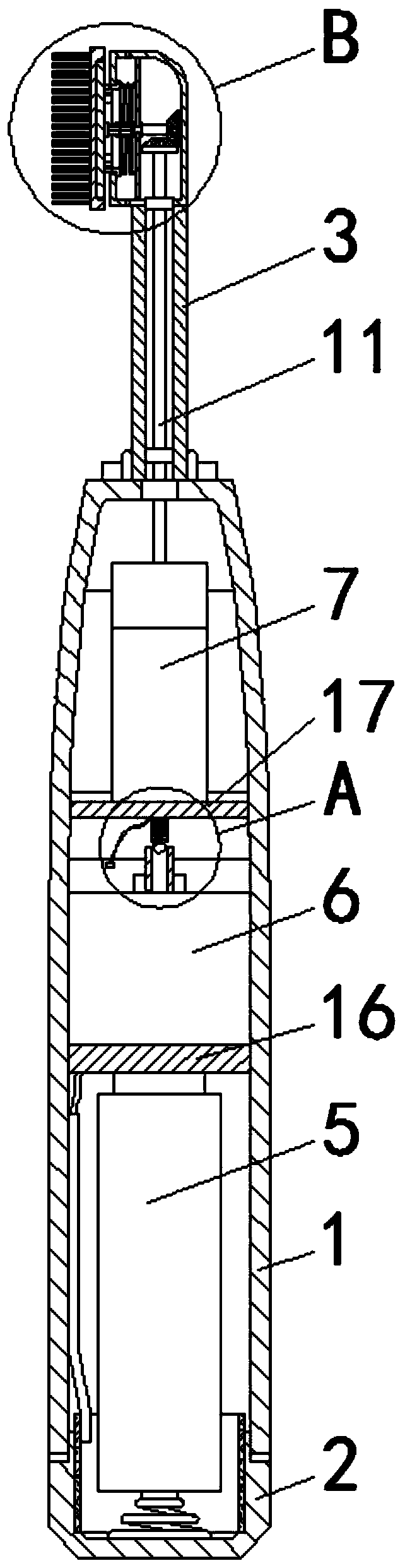

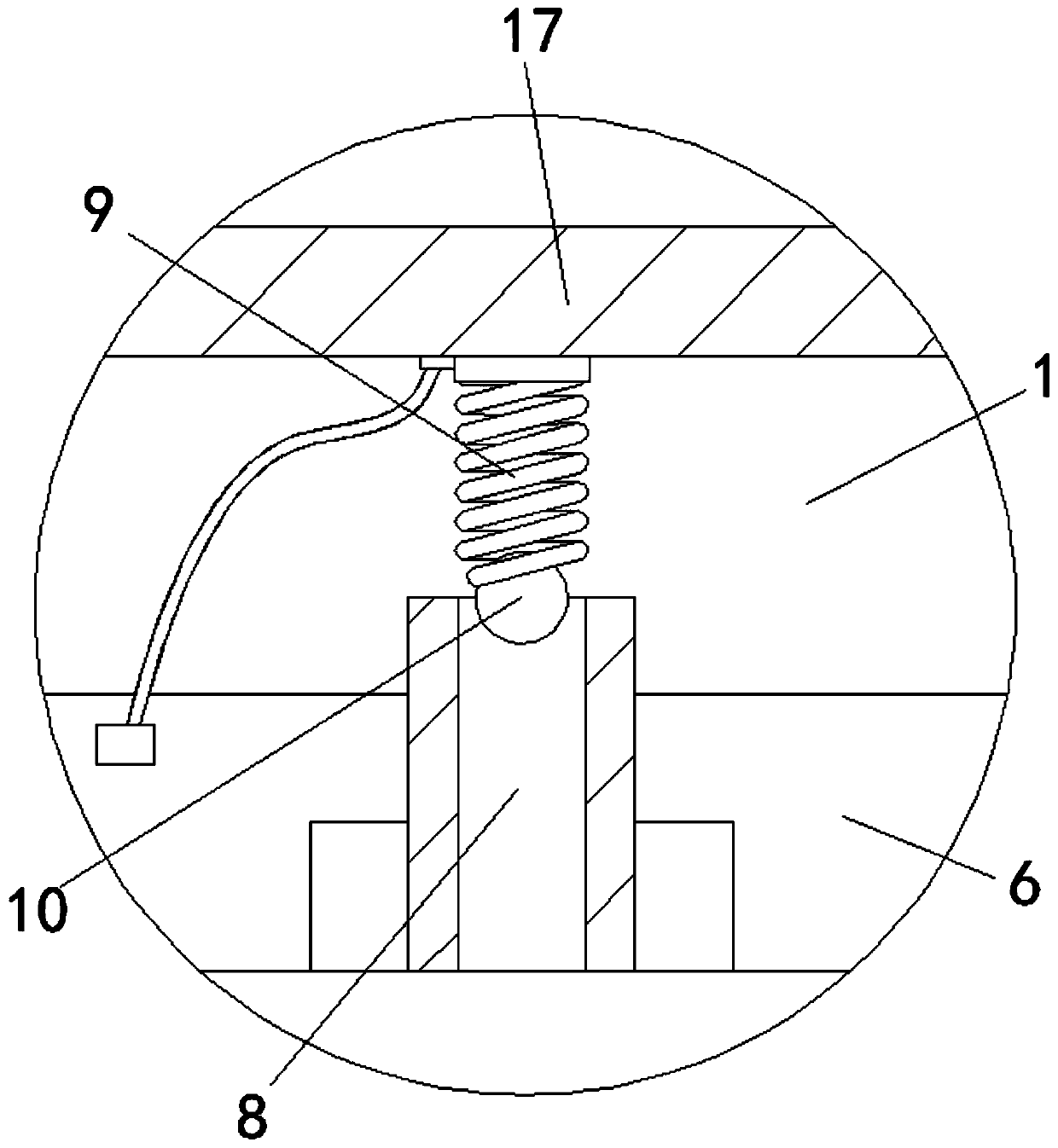

Intelligent electric toothbrush with shaking shutdown function

PendingCN110755168AEasy to replaceWith shake to shutdown functionTooth cleaningBristleStructural engineering

The invention relates to the technical field of electric toothbrushes, and discloses an intelligent electric toothbrush with a shaking shutdown function, which comprises a shell, a sealing cover is fixedly installed at the bottom of the shell, a connecting cylinder is fixedly installed at the top of the shell, a brush head communicated with the connecting cylinder is fixedly installed at the top of the connecting cylinder, and a first partition plate is fixedly installed in the shell. According to the intelligent electric toothbrush with the shaking shutdown function, the mistaken-touch-preventing shaking opening and closing operations can be carried out; internal water inflow caused by damage of a button waterproof part is avoided; when a traditional electric toothbrush is used, a switchneeds to be pressed to achieve startup and shutdown operation; and meanwhile, the contact force between the exterior of a hairbrush sleeve and the teeth of the user can be reduced, the situation thatthe teeth are greatly abraded due to excessive force is avoided, the use experience of the user is improved, the user can replace the bristles conveniently, and the replacement and maintenance cost islow.

Owner:深圳芯品智半导体技术有限公司

Carbon fiber hollow heating rod column

InactiveCN110778280AImprove efficiencyReduce replacement and maintenance costsDrilling rodsInsulationAdhesive cementFiber

The invention discloses a carbon fiber hollow heating rod column which comprises a plurality of carbon fiber hollow sucker rods and a metal hollow double-end joint. Each carbon fiber hollow sucker rodcomprises a metal joint, an adhesive, a seal ring and a carbon fiber hollow pipe. One end of each metal joint is bonded to the outer side of one end of the corresponding carbon fiber hollow pipe through the adhesive, an inner thread is arranged at the other end of each metal joint, outer threads adaptive to the inner threads of the metal joints are arranged on the outer sides of two ends of the metal hollow double-end joint, two ends of the metal hollow double-end joint are in threaded connection to the metal joints at one ends of the two carbon fiber hollow pipes, and each seal ring is arranged at the end, bonded to the pipe wall of the corresponding carbon fiber hollow pipe, of the corresponding metal joint. The carbon fiber hollow heating rod column has the beneficial effects that thecarbon fiber hollow sucker rods are connected and communicate through the metal hollow double-end joint, so that the problem that the using effect of the carbon fiber hollow sucker rods is affected directly in use of the carbon fiber hollow sucker rods as a result of wax precipitation or viscosity in an oil well is solved, the oil suction efficiency is improved, and the replacement and maintenancecosts are lowered.

Owner:大庆市汇成科技开发有限公司

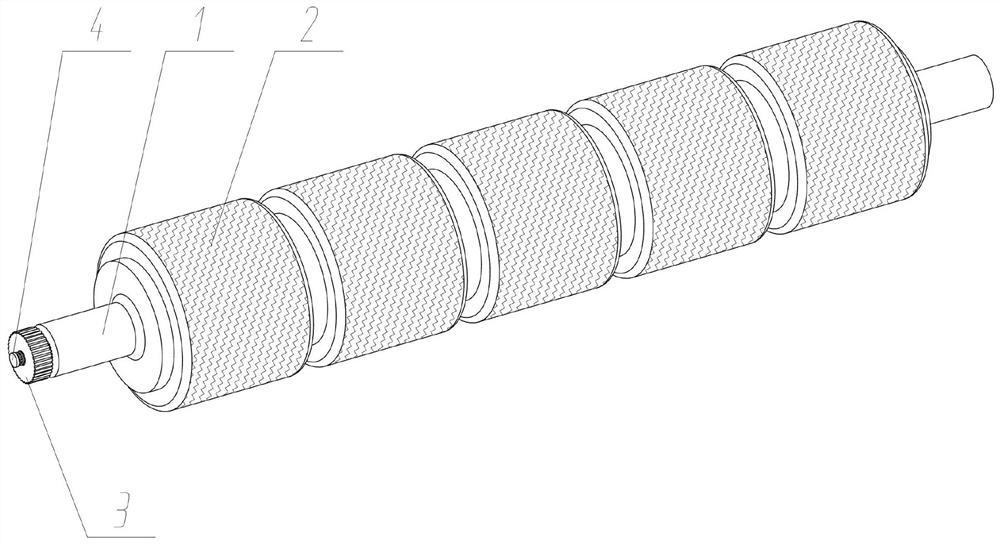

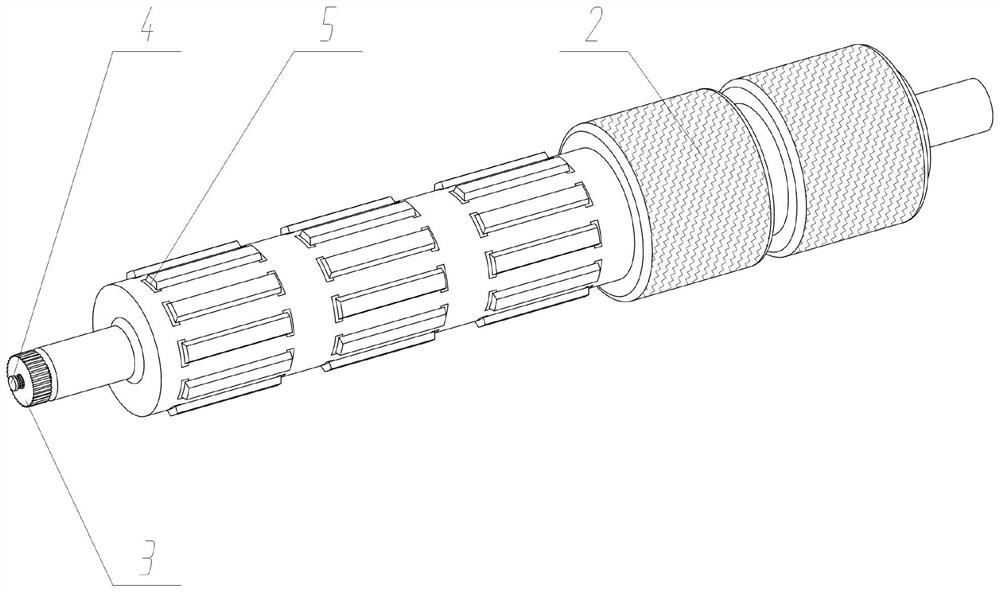

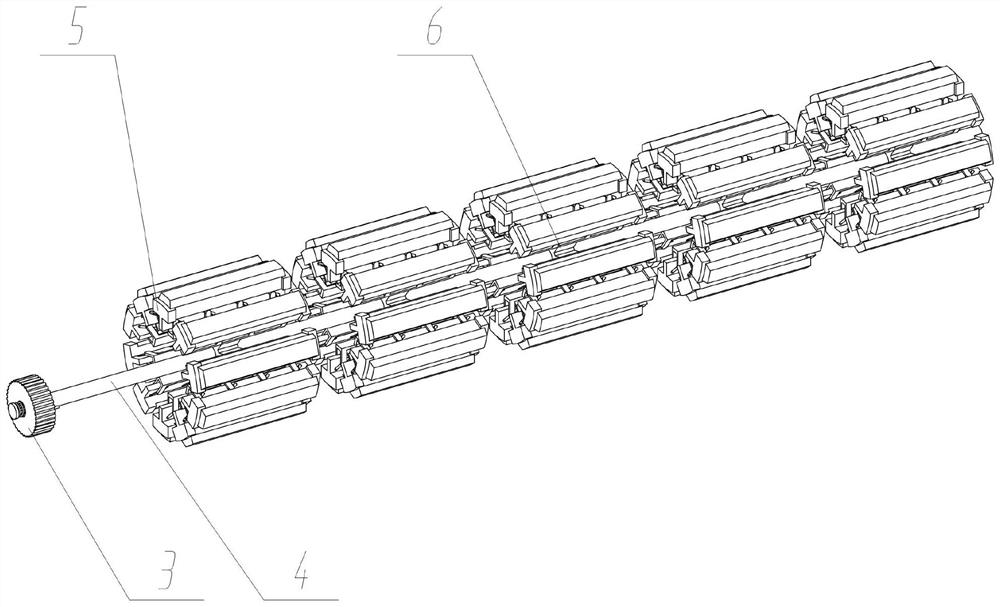

Roller device for textile machine

InactiveCN112553721AReduce replacement and maintenance costsPrevent looseningDrafting machinesStructural engineeringMechanical engineering

The invention discloses a roller device for a textile machine, relates to the technical field of textile machines, solves the problems that after an existing roller is used for a long time, recesses,eccentricity, big ends and small ends are generated, the diameters of two rollers on a same set are inconsistent, the surfaces of the rollers are finely cracked, surface treatment layers of the rollers are peeled off or loses efficacy and the like, and also solves the problem that the integrated roller needs to be integrally replaced if being damaged in a using process, and the replacement cost ishigh. The integrated roller comprises a roller shaft; wherein the center of the roller shaft is rotationally connected with a set of locking adjusting lead screws; a set of locking operation pieces are connected to the left end face of the locking adjusting lead screw in a sliding mode; and a set of rollers are connected to the outer sides of locking pieces located at the same section position ina tightly-supported mode. By the adoption of the split type roller barrel, part of the roller barrel can be replaced according to the abrasion condition and the deformation condition, the replacementand maintenance cost of the roller is reduced, mounting and dismounting are convenient, looseness of a lead screw nut pair caused by vibration is effectively prevented, and the working stability of the roller is guaranteed.

Owner:温州瓦序鞋业有限公司

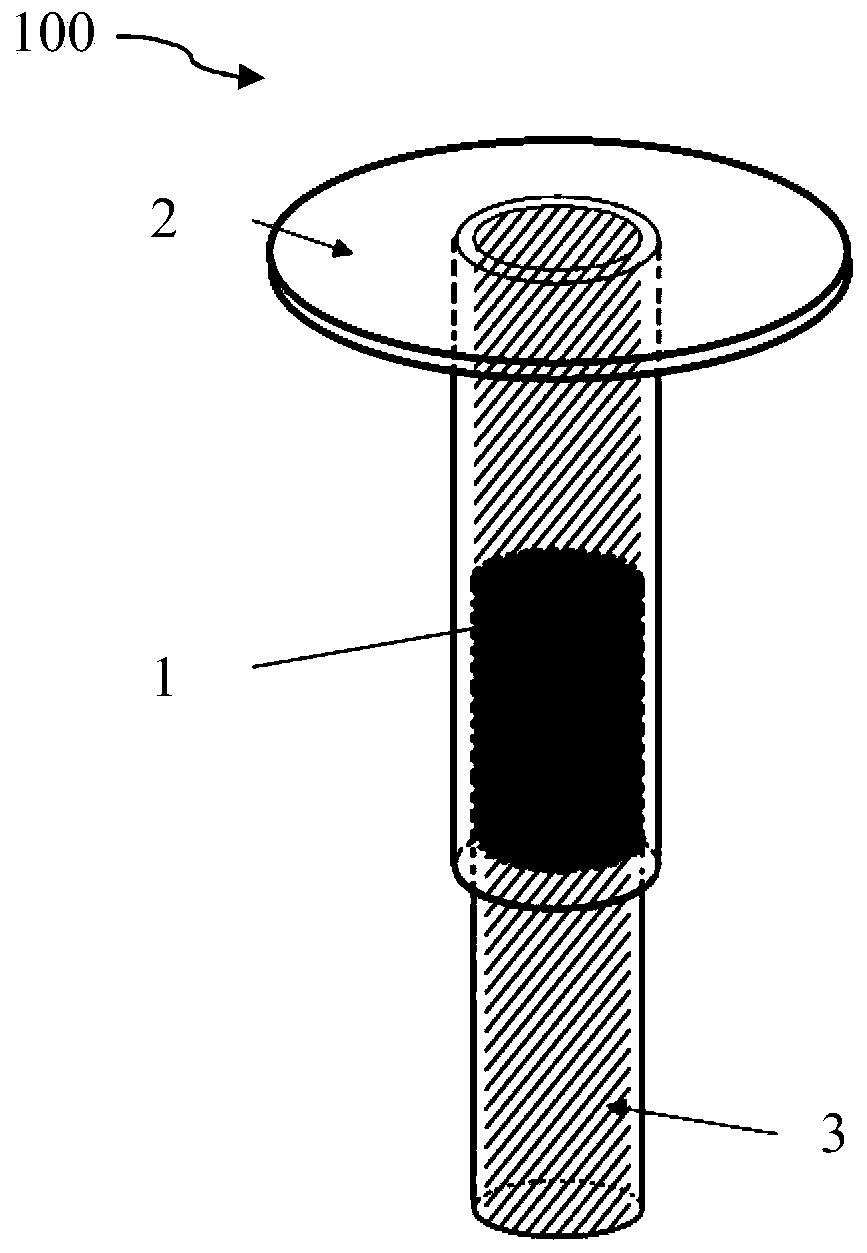

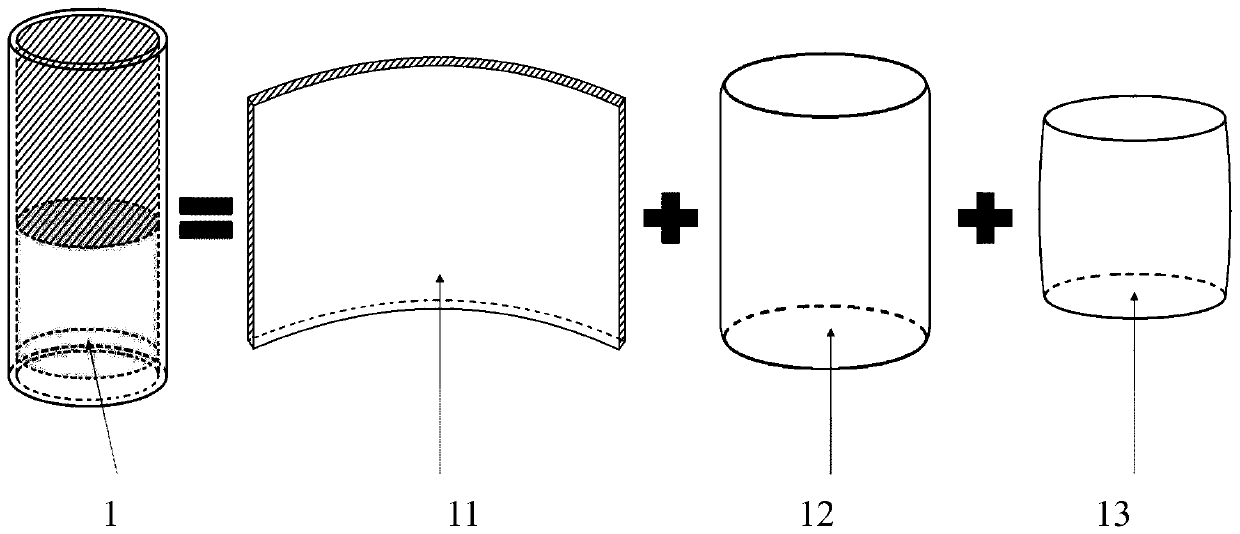

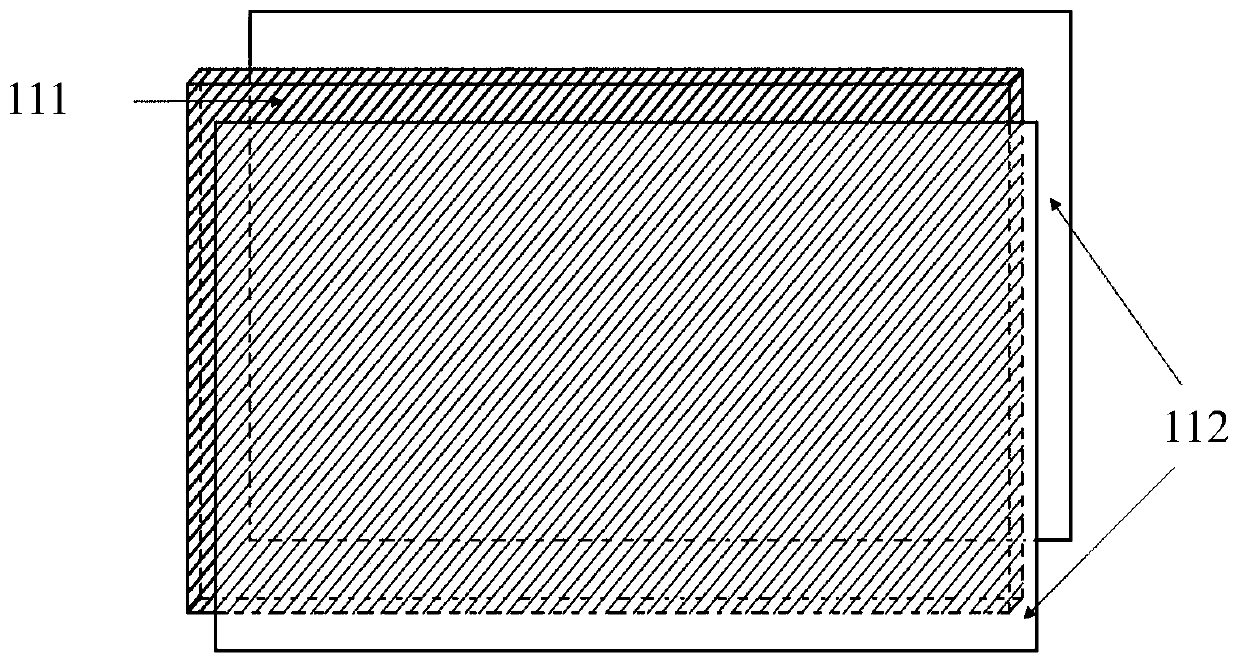

Battery heat dissipation and pressure relief energy recovery explosion-proof structure and device and manufacturing methods thereof

ActiveCN110970685AReduce the possibility of explosion hazardsExtended service lifeSecondary cellsBismuth tellurideMechanical engineering

The invention is suitable for the technical field of battery heat dissipation and pressure relief energy recovery, and provides a battery heat dissipation and pressure relief energy recovery explosion-proof structure and device and manufacturing methods thereof. The battery heat dissipation and pressure relief energy recovery explosion-proof structure comprises a heat dissipation explosion-proof pipe and a semiconductor energy recovery ring, the heat dissipation explosion-proof pipe is of a cylindrical structure, the semiconductor energy recovery ring is of a flat circular ring structure, thesemiconductor energy recovery ring is nested at the top of the heat dissipation explosion-proof pipe, and the heat dissipation explosion-proof pipe comprises a heat dissipation explosion-proof pipe shell and a heat dissipation explosion-proof pipe filler; and the heat dissipation explosion-proof pipe shell and the semiconductor energy recovery ring comprises a bismuth telluride semiconductor chilling plate and two pieces of soft ceramic, and the bismuth telluride semiconductor chilling plate is arranged between the two pieces of soft ceramic. According to the battery heat dissipation and pressure relief energy recovery explosion-proof structure provided by the invention, the cooling or heating speed of the battery is high, the explosion-proof performance of the battery is high, part of energy can be recovered, and meanwhile, the capacity of the battery cannot be lost due to low temperature.

Owner:深圳市上欧新材料有限公司

Explosion-proof structure, device and manufacturing method of battery heat dissipation and pressure relief energy recovery

ActiveCN110970685BReduce the possibility of explosion hazardsExtended service lifeSecondary cellsBismuth tellurideEnergy recovery

The invention is suitable for the technical field of battery heat dissipation and pressure relief energy recovery, and provides a battery heat dissipation and pressure relief energy recovery explosion-proof structure and device and manufacturing methods thereof. The battery heat dissipation and pressure relief energy recovery explosion-proof structure comprises a heat dissipation explosion-proof pipe and a semiconductor energy recovery ring, the heat dissipation explosion-proof pipe is of a cylindrical structure, the semiconductor energy recovery ring is of a flat circular ring structure, thesemiconductor energy recovery ring is nested at the top of the heat dissipation explosion-proof pipe, and the heat dissipation explosion-proof pipe comprises a heat dissipation explosion-proof pipe shell and a heat dissipation explosion-proof pipe filler; and the heat dissipation explosion-proof pipe shell and the semiconductor energy recovery ring comprises a bismuth telluride semiconductor chilling plate and two pieces of soft ceramic, and the bismuth telluride semiconductor chilling plate is arranged between the two pieces of soft ceramic. According to the battery heat dissipation and pressure relief energy recovery explosion-proof structure provided by the invention, the cooling or heating speed of the battery is high, the explosion-proof performance of the battery is high, part of energy can be recovered, and meanwhile, the capacity of the battery cannot be lost due to low temperature.

Owner:深圳市上欧新材料有限公司

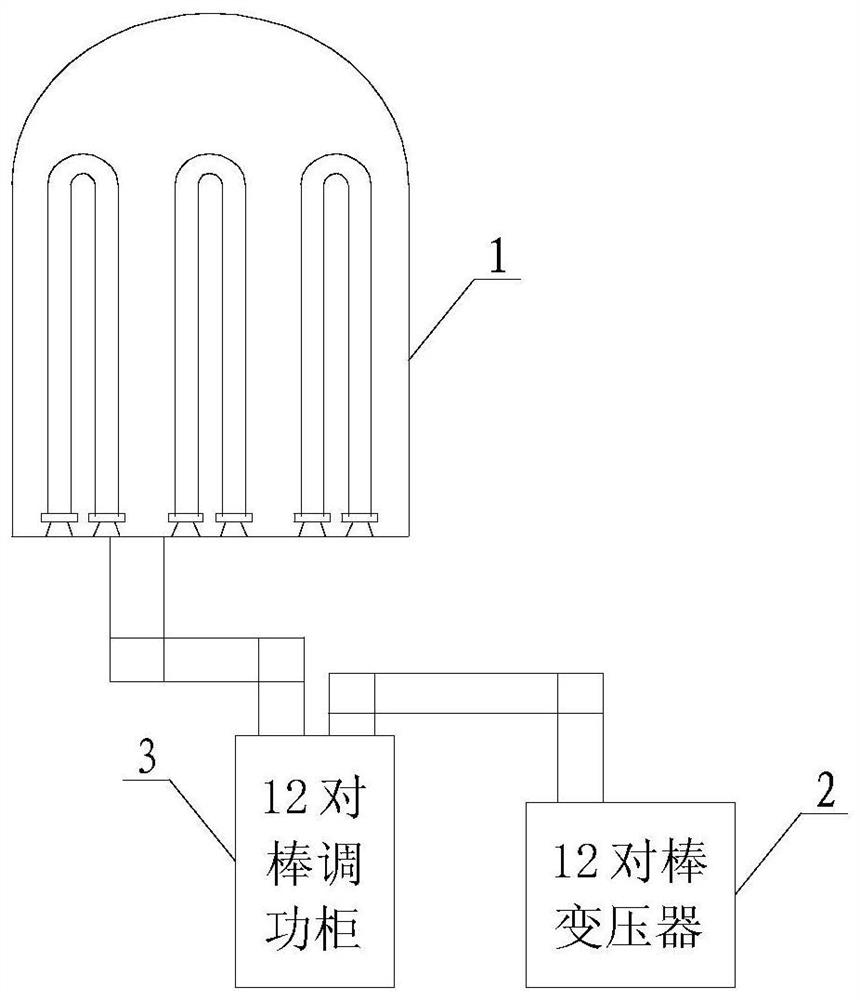

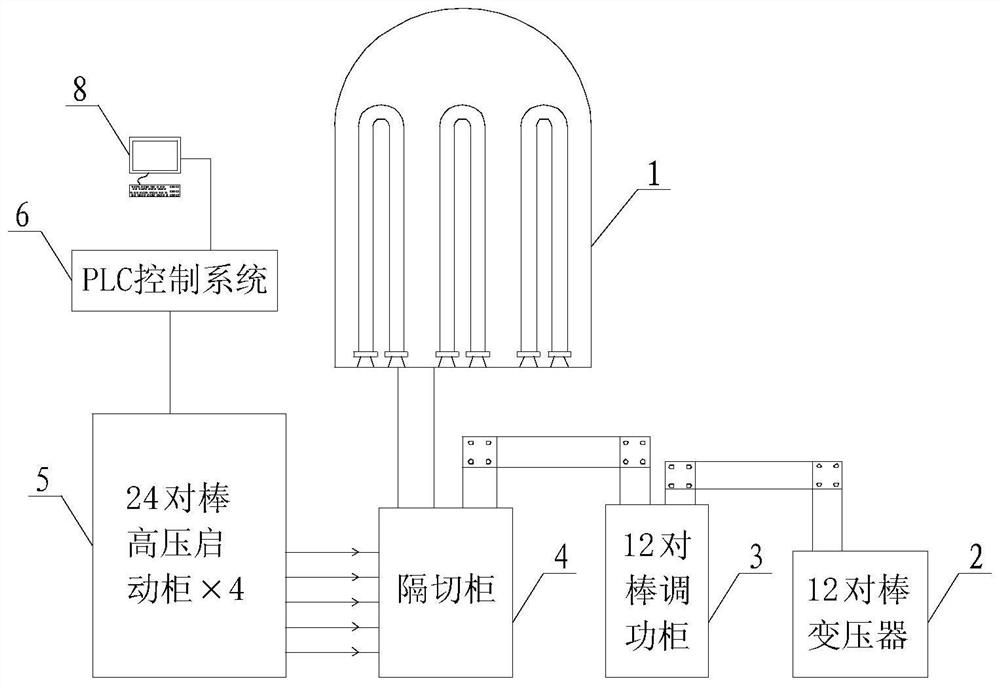

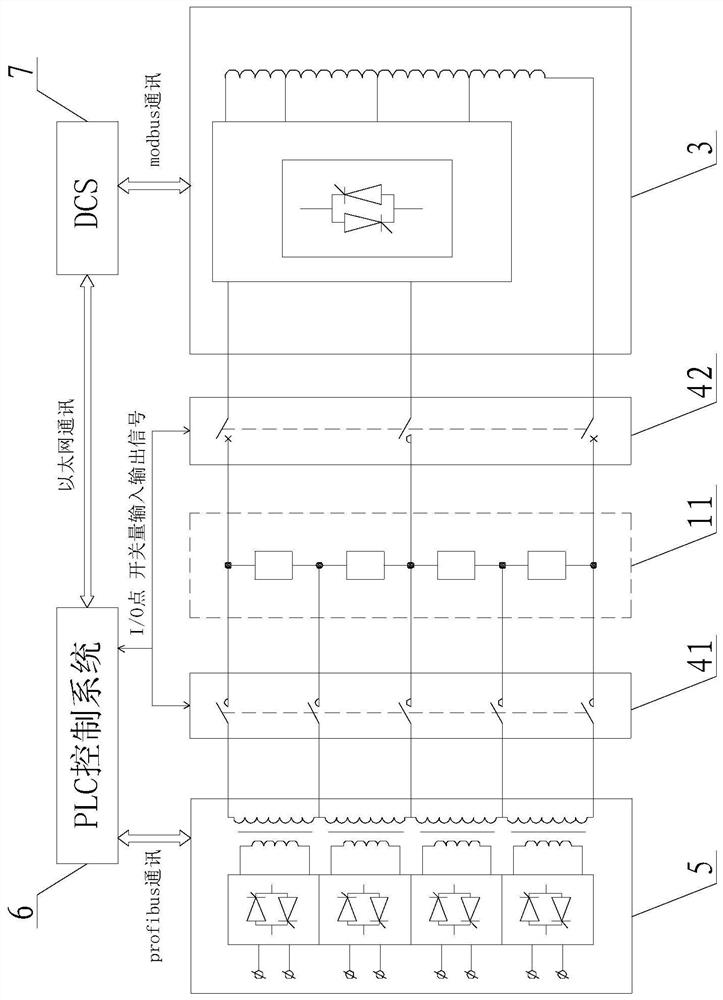

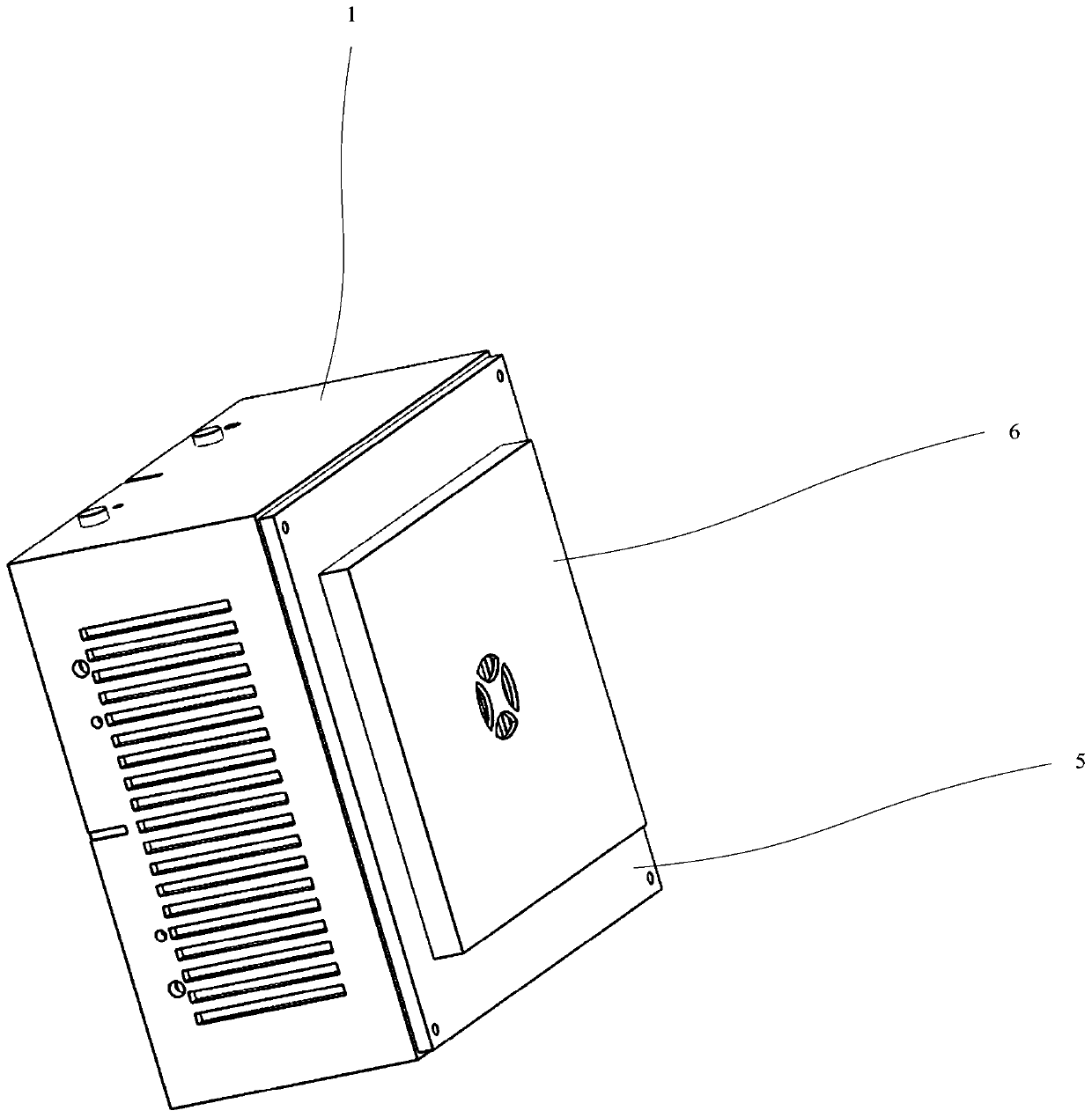

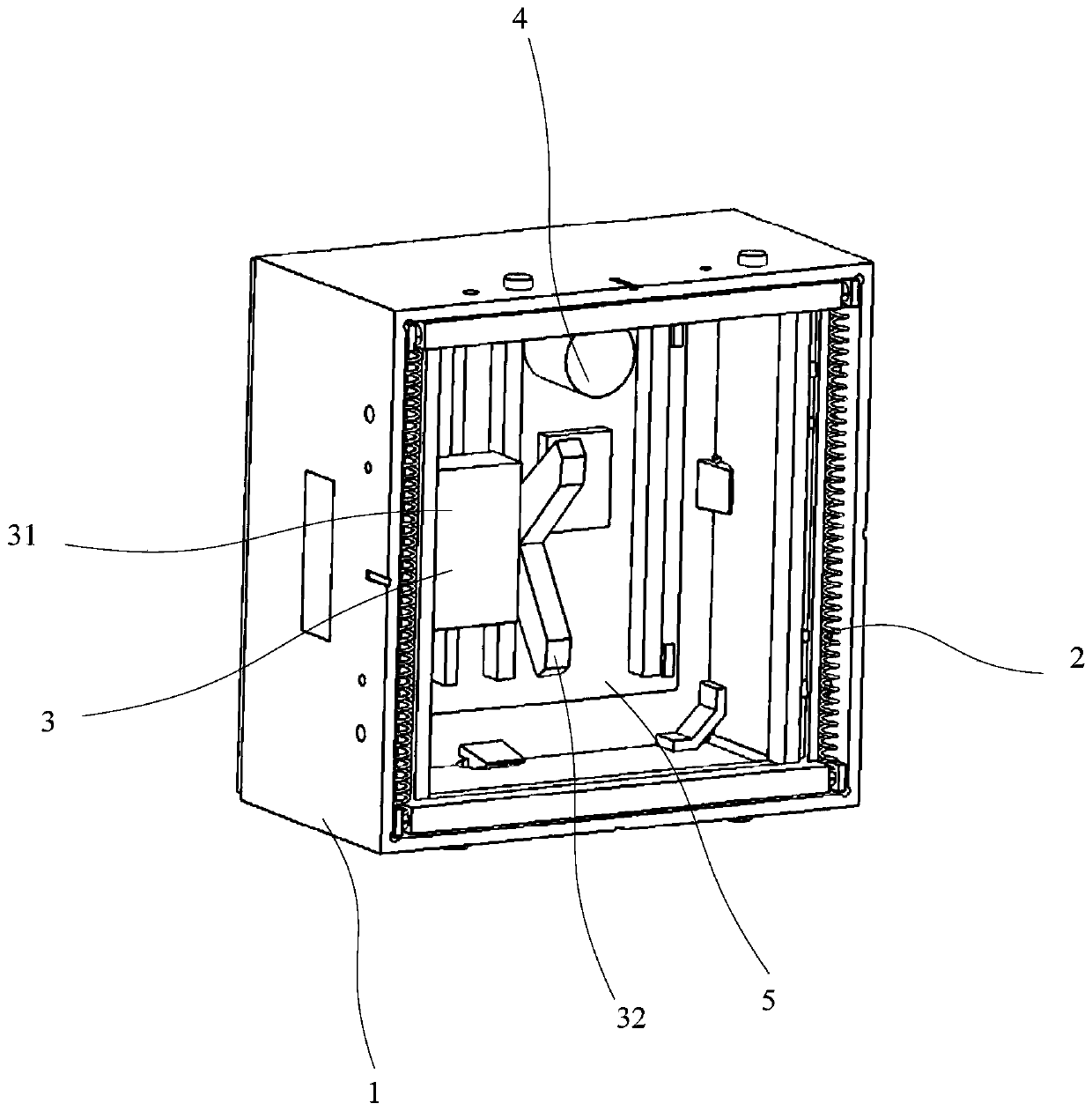

System and method for high-pressure start-up of reduction furnace

ActiveCN110482554BLess investment in transformationReduce startup timeSilicon compoundsEngineeringThree-phase

The invention provides a reduction furnace high-voltage starting system. A 12-rod-pair power adjusting cabinet and a 24-rod-pair high-voltage starting system are connected to a silicon core of a reduction furnace through a separation switching cabinet respectively. After the 24-rod-pair high-voltage starting system is connected with a single-phase silicon core under switching by the separation switching cabinet, the 24-rod-pair high-voltage starting system is used for applying a breakdown voltage to the single-phase silicon core until breakdown of the single-phase silicon core. The 12-rod-pairpower adjusting cabinet is used for connection with the single-phase silicon core in preset time after breakdown of the silicon core and under switching by the separation switching cabinet, and is used for applying a preset voltage to the silicon core to keep the silicon core in a conducting state. The 12-rod-pair power adjusting cabinet, the separation switching cabinets and the 24-rod-pair high-voltage starting system cooperate with each other to perform high-voltage breakdown and switching of a next single-phase silicon core until silicon cores in three phases are all connected to the 12-rod-pair power adjusting cabinet. Correspondingly, a high-voltage starting method for the reduction furnace high-voltage starting system is provided. The reduction furnace high-voltage starting systemand method can ensure rapid breakdown of the silicon cores and do not damage elements of the 12-rod-pair power adjusting cabinet.

Owner:XINTE ENERGY

Non-contact pressing device for remotely controllable lighting lamp switch

PendingCN110299260AReduce replacement and maintenance costsElectric light circuit arrangementEnergy saving control techniquesEngineeringSurface plate

Owner:YANGTZE UNIVERSITY

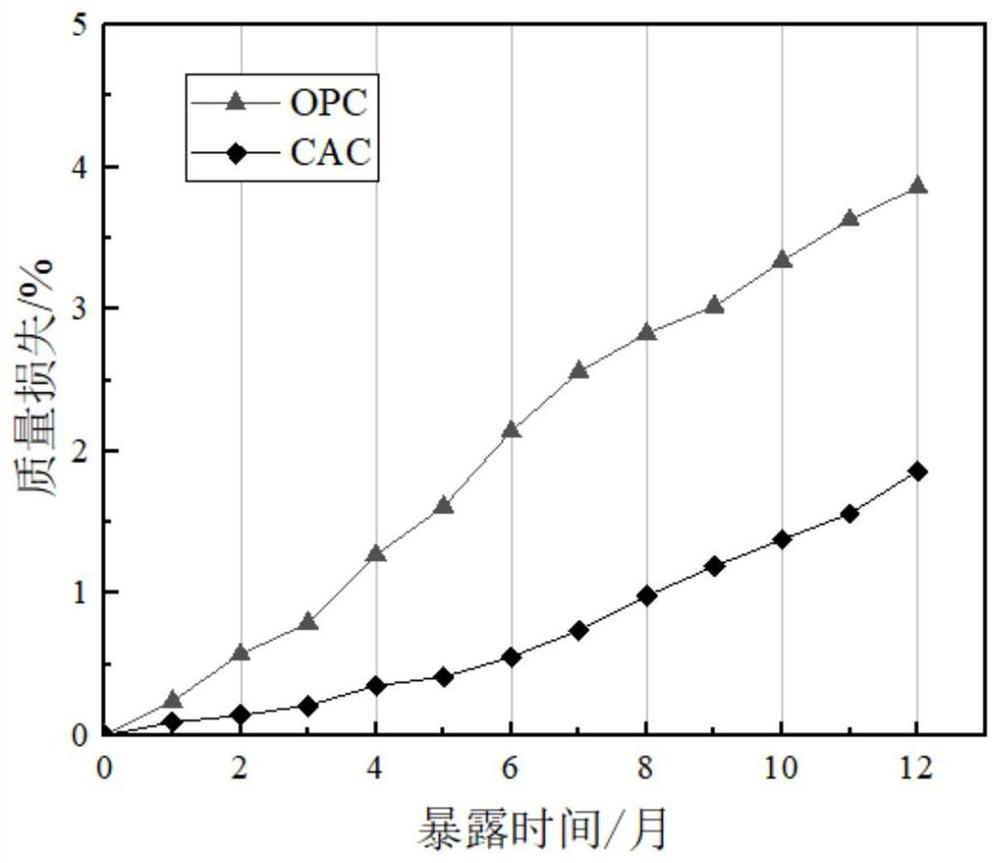

A kind of corrosion-resistant aluminate cement pipe and its preparation method

The invention belongs to the technical field of building materials, and specifically relates to a corrosion-resistant aluminate cement pipeline and a preparation method thereof. Aluminate cement and slag are used as cementitious materials. The quality of the aluminate cement: the quality of the slag=80-90 : 10-20, made by using active and reactive dolomite as aggregate. The anti-corrosion aluminate cement pipeline provided by the present invention has significantly better corrosion resistance in the sewage environment than the sewage concrete made of ordinary Portland cement as the main cementitious material and conventional siliceous sand as the aggregate Pipes can achieve the purpose of reducing the cost of replacing and maintaining sewage concrete pipes.

Owner:TONGJI UNIV

Anti-melting aluminum corrosion coating and preparation method thereof

ActiveCN110195228BHigh temperature wear resistanceAccelerated corrosionHot-dipping/immersion processesLiquid surface applicatorsAlloyAluminum corrosion

Owner:SHANGHAI JUSN SURFACE TECH ENG

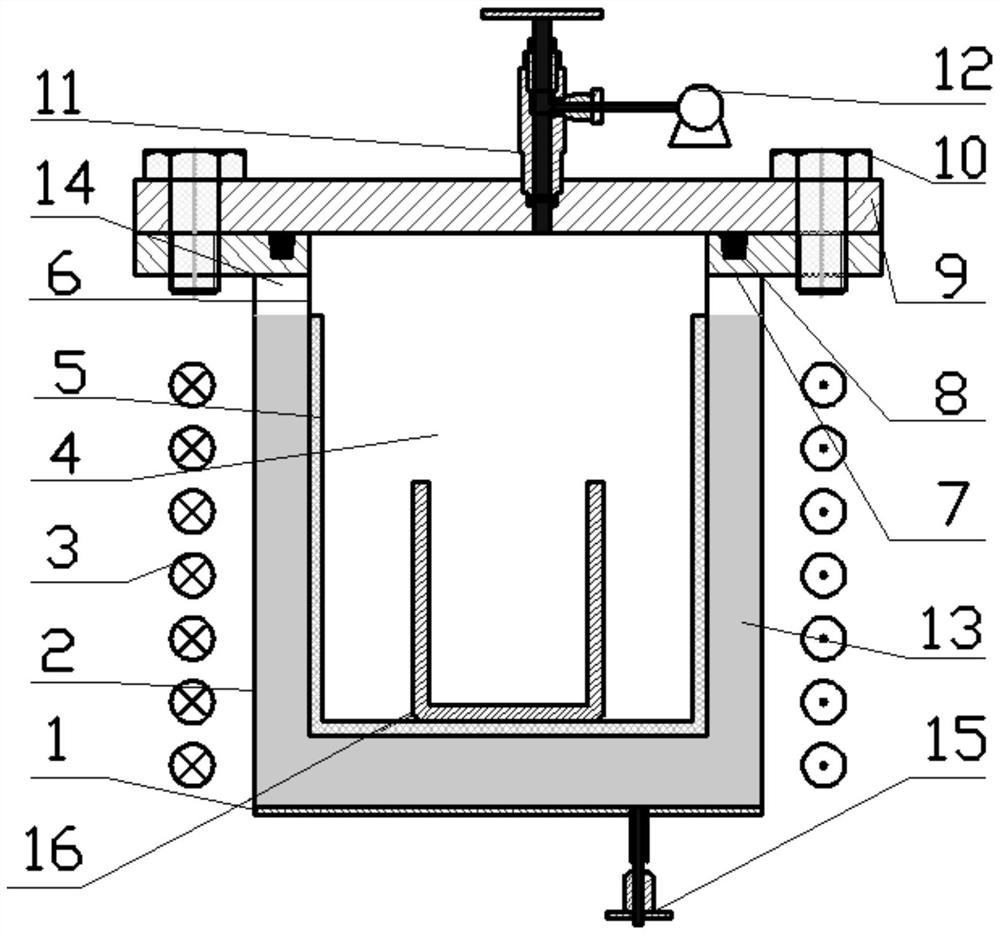

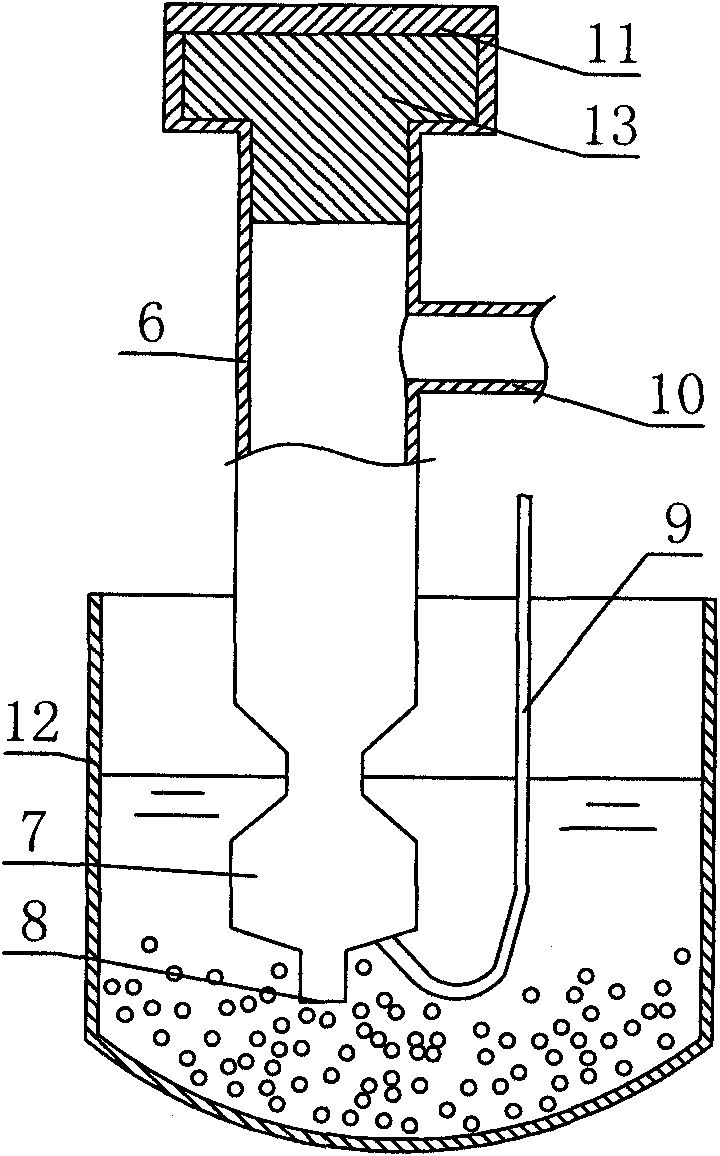

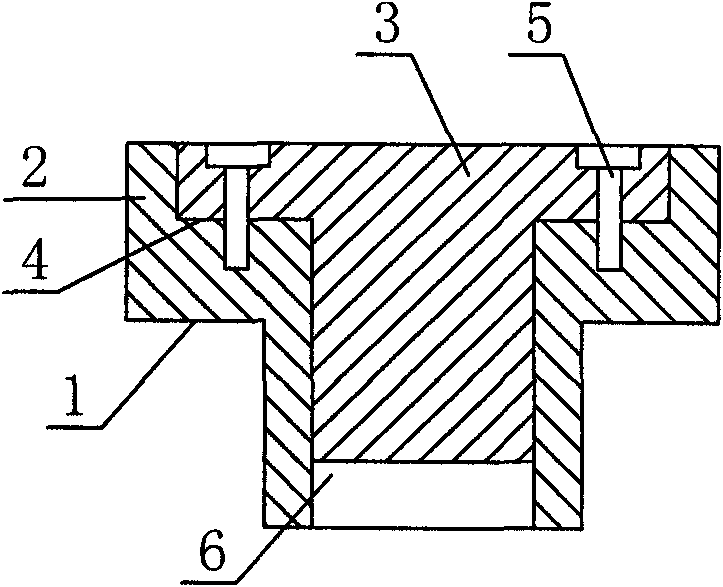

A liquid metal temperature control vacuum induction melting device and temperature control method

Owner:威镝精工科技(苏州)有限责任公司

Stripping machine liner

InactiveCN101806313AEasy to replace and maintainReduce maintenance costsMachines/enginesRecycling and recovery technologiesEngineeringMechanical engineering

The invention discloses a stripping machine liner which is overall a longitudinal cylindrical body, and bearing parts horizontally extend from the upper end to the periphery; the liner is characterized in that the overall stripping machine liner comprises an outer liner shell and an inner liner core which are tightly sleeved together; the liner core is overall a longitudinal cylindrical body, and the bearing parts horizontally extend from the upper end to theperiphery; and the upper surface of each bearing part connects the liner shell and the liner core together through a downward screw. The liner in the technical scheme comprises the liner shell and the liner core which are connected together by the screw when in use, and does not affect the use effect; simultaneously, the part around the liner which is not easy to wear is the liner shell, and the central part which is easy to wear is the liner core; consequently, when the middle of the liner is worn and punctured, only the liner core needs to be replaced, and the weight of the liner core is far lower than the overall weight of the liner, so the replacement can be carried out without any crane, so that the replacement is convenient; and simultaneously, the single replacement of the line core can reduce the replacement and maintenance cost.

Owner:CHONGQING IRON & STEEL (GRP) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com