Near-zero OD backlight module and Mini LED lamp bead manufacturing method thereof

A backlight module, near-zero technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems that the thickness of the backlight module cannot be further reduced, high processing cost, and high processing difficulty, so as to reduce replacement and maintenance costs and increase production capacity , to avoid the effect of organic silica gel residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The purpose of the present invention can be achieved through the following technical solutions:

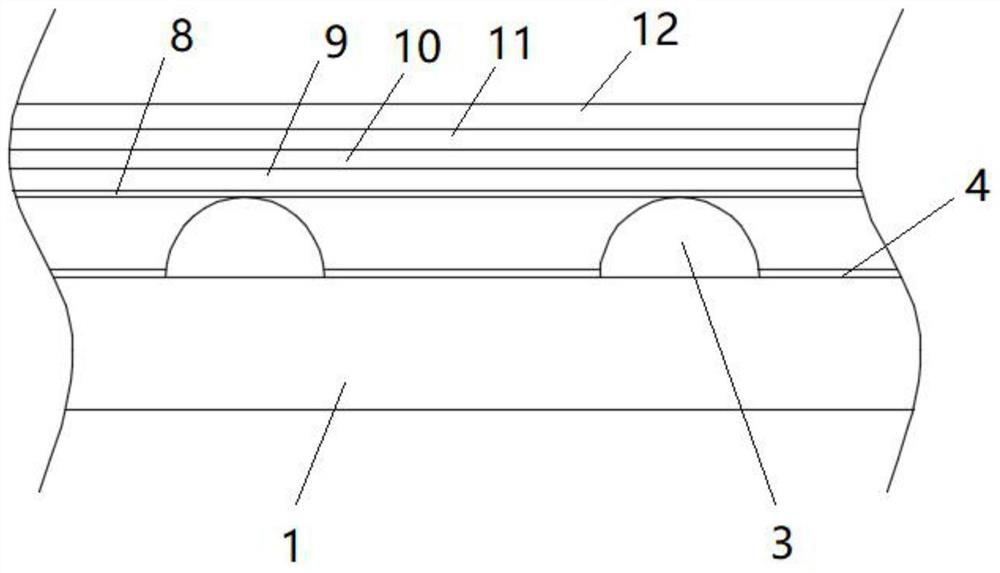

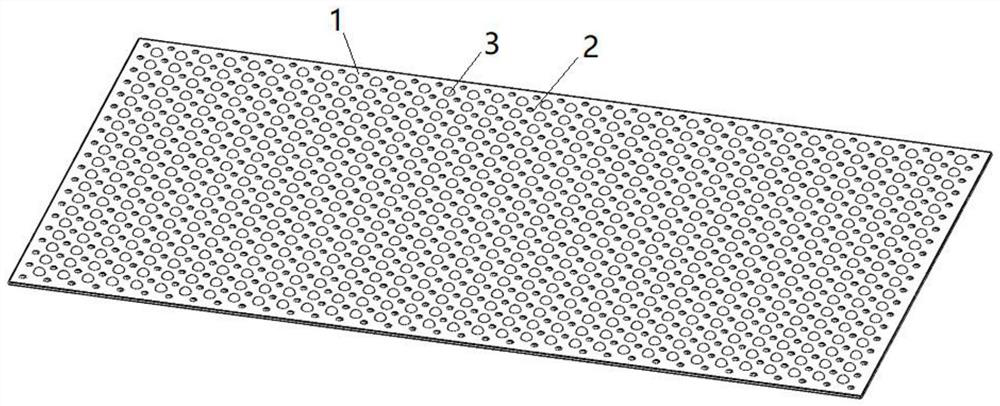

[0046] A near-zero OD backlight module, see Figure 1~4 , including PCB board 1, lens processing adsorption hole 2, Mini LED lamp bead 3, reflective paper 4, diffusion sheet 8, diffusion plate 9, quantum dot film 10, prism sheet 11, LCD screen 12;

[0047] The back of the PCB board 1 is provided with a back plate, and the top of the PCB board 1 is sequentially provided with a diffusion sheet 8, a diffusion sheet 9, a quantum dot film 10, a prism sheet 11, and a liquid crystal screen 12; the PCB board 1 is not provided with a bracket, and through Bracket design to further reduce the thickness of the backlight module;

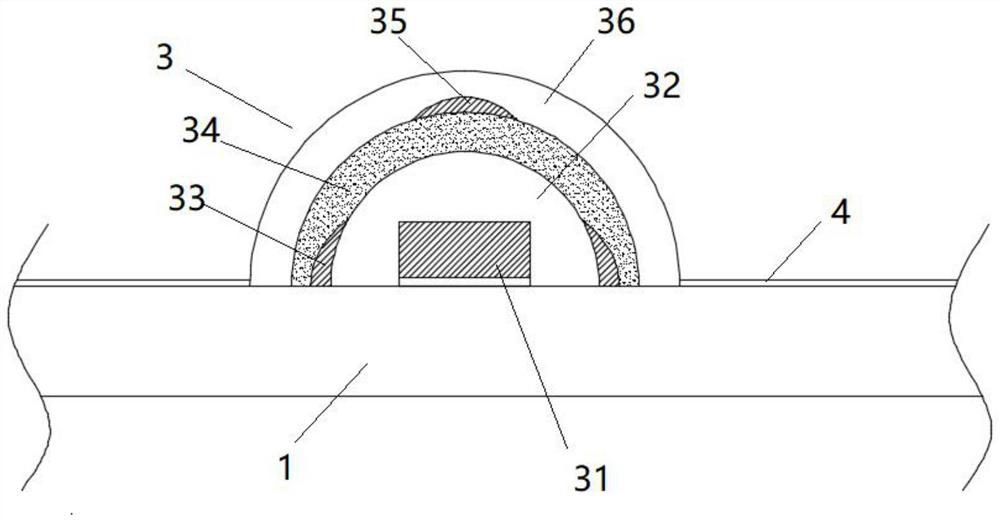

[0048] The Mini LED lamp bead 3 includes a Mini LED chip 31 and a lens, the Mini LED chip 31 is welded on the LED chip pad of the PCB board 1, and the lens wraps the Mini LED chip 31; the top of the lens is in direct contact with the diffuser 8;

[0049] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com