Roller device for textile machine

A technology for textile machinery and top rollers, which is applied to spinning machines, textiles, papermaking, and drafting equipment. It can solve problems such as inconsistent diameters of top rollers, micro cracks on the surface, and peeling off of the surface treatment layer to reduce replacement and maintenance costs. , Guaranteed working stability, convenient installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

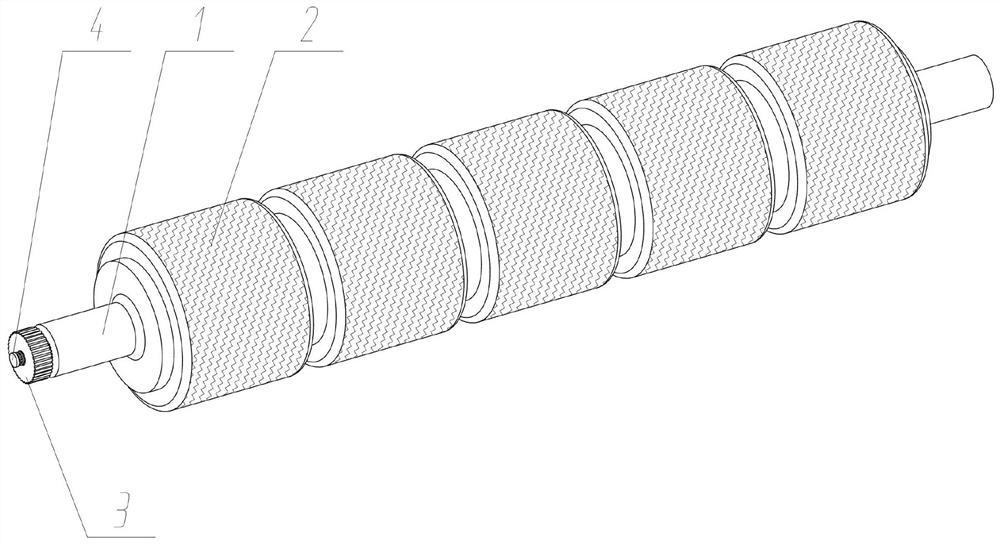

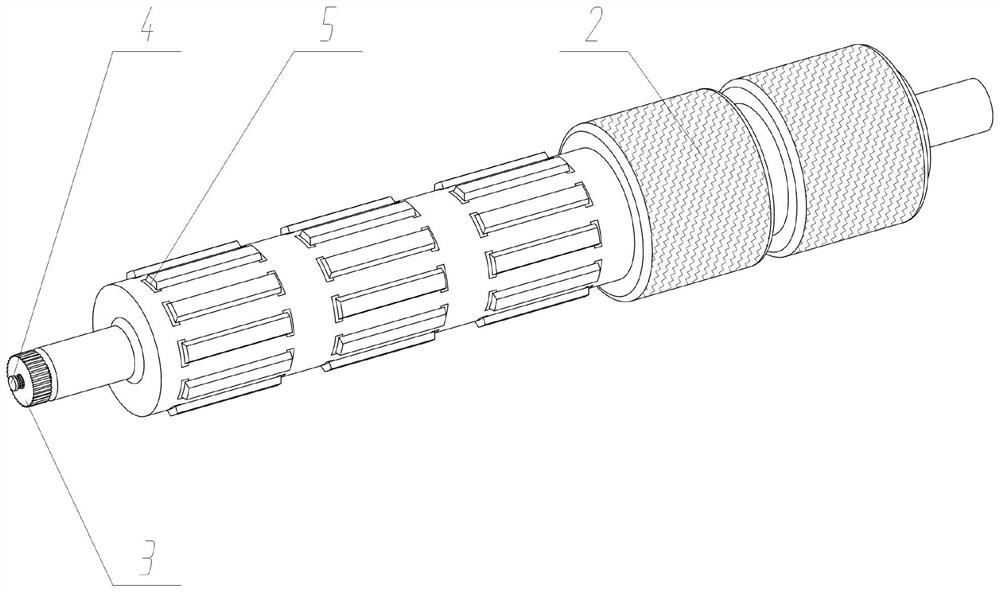

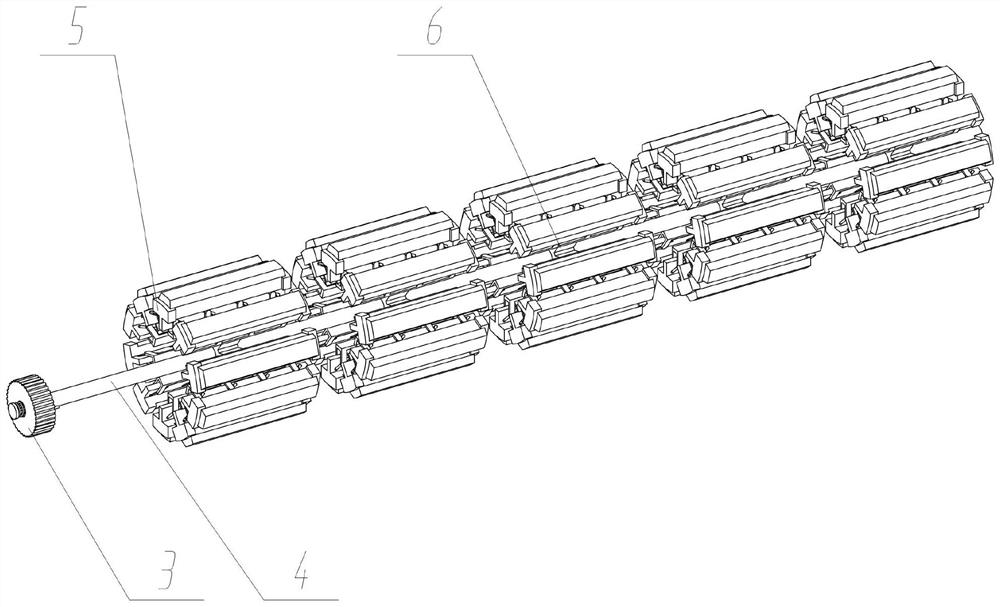

[0032] see Figure 1 to Figure 10 , a roller top roller device for textile machinery, including a roller shaft 1; a group of locking adjustment screw 4 is connected to the center of the roller shaft 1 for rotation; a group of locking operation is slidingly connected to the left end surface of the locking adjustment screw 4 Part 3; the inner sliding connection of the roller shaft 1 has five sets of locking drive blocks 6; the outer circumferential array of the roller shaft 1 is evenly arranged and slidingly connected with locking parts 5; A group of top rollers 2 are connected.

Embodiment 2

[0034] The locking operating part 3 also includes a spline shaft hole 301 and a compression spring 303. A group of spline shaft holes 301 are provided in the middle of the locking operating part 3. The locking adjusting screw 4 also includes a sliding spline shaft 401, A set of sliding spline shafts 401 is coaxially and fixedly connected to the left end face of the locking adjustment screw 4, and the sliding spline shafts 401 are slidably connected to the spline shaft holes 301, and a set of compression springs 303 are arranged on the left side of the locking operation part 3 , the locking operating member 3 is elastically connected to the locking adjusting screw 4 through the compression spring 303 , and in use, the locking operating member 3 is pushed to the right by the compression spring 303 .

Embodiment 3

[0036] The roller shaft 1 also includes locking positioning holes 101, and the left end surface of the roller shaft 1 is arranged in a circumferential array with the locking positioning holes 101. The locking operating part 3 also includes a positioning pin 302, and the right end surface of the locking operating part 3 is fixed. There are two sets of positioning pins 302 connected, and the positioning pins 302 are connected to the locking positioning hole 101. In use, the locking operation part 3 and the roller shaft 1 are realized through the plugging connection of the positioning pins 302 and the locking positioning hole 101. between positioning.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com