Stripping machine liner

An air lift and liner technology, applied in the field of the liner structure of the air lifter, can solve the problems of inconvenience, high maintenance cost, and affecting the work of the air lifter, and achieve the effects of long service life, convenient replacement and maintenance, and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

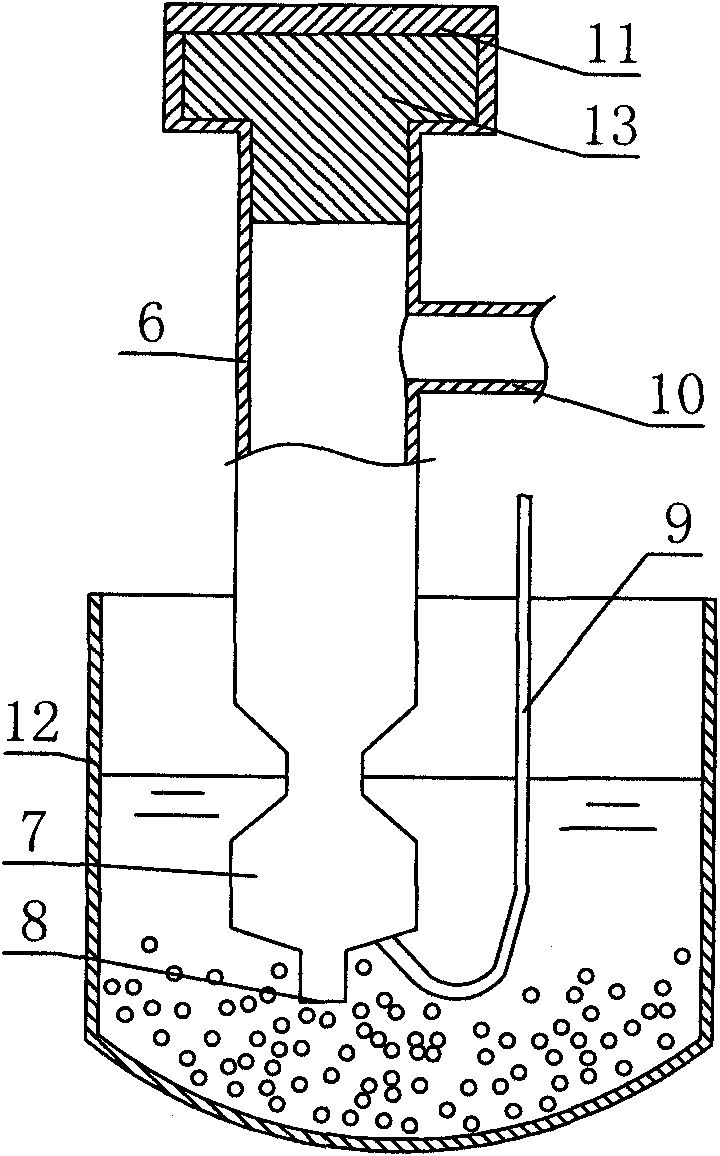

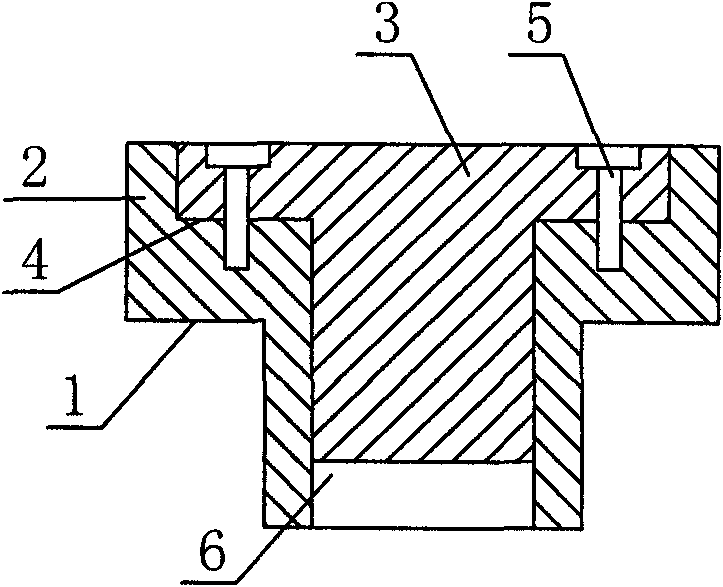

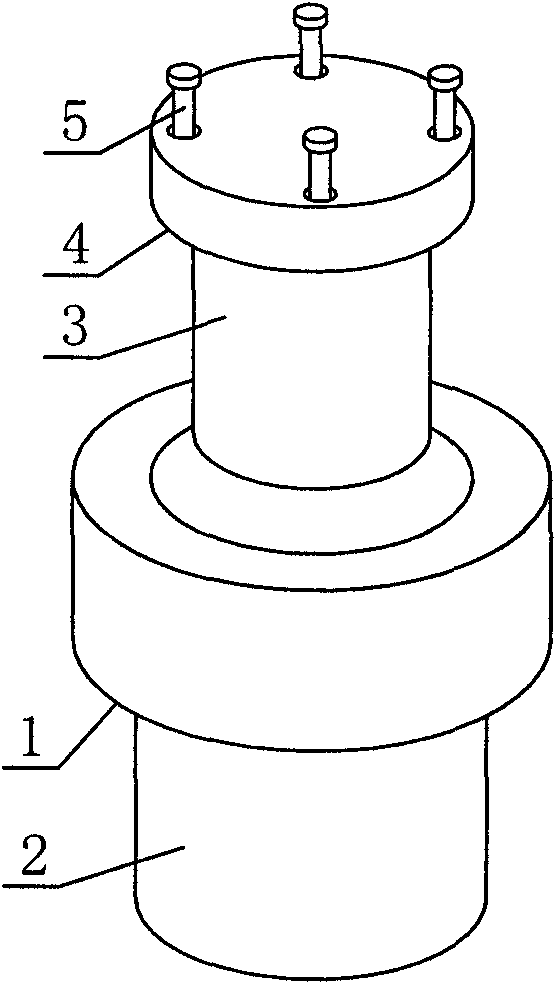

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0015] In specific implementation, such as figure 2 As shown, a kind of air lifter liner, its whole is longitudinal columnar body, and its upper end extends laterally around a supporting part 1, wherein, described air lifter liner overall is made up of outer liner shell 2 and inner liner The core 3 is tightly socketed, and the core 3 is a longitudinal column as a whole, and a support portion 4 extends laterally from its upper end to the surroundings, and the upper surface of the support portion 4 is connected by the screw 5 arranged downward to make the shell 2 and the core 3 are connected as one; the length of the lower end of the bladder core 3 is less than the length of the lower end of the bladder shell 2, so that an upward groove 6 is formed under the inner tank after the bladder core 3 and the bladder shell 2 are sleeved as a w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com