A kind of corrosion-resistant aluminate cement pipe and its preparation method

A kind of aluminate cement and anti-corrosion technology, which is applied in the field of building materials, can solve the problems of microbial corrosion damage, durability reduction of concrete pipeline structure, and reduce the cost of replacement and maintenance of sewage pipeline infrastructure, so as to reduce corrosion damage and ensure antibacterial corrosion Performance and reduction of replacement and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

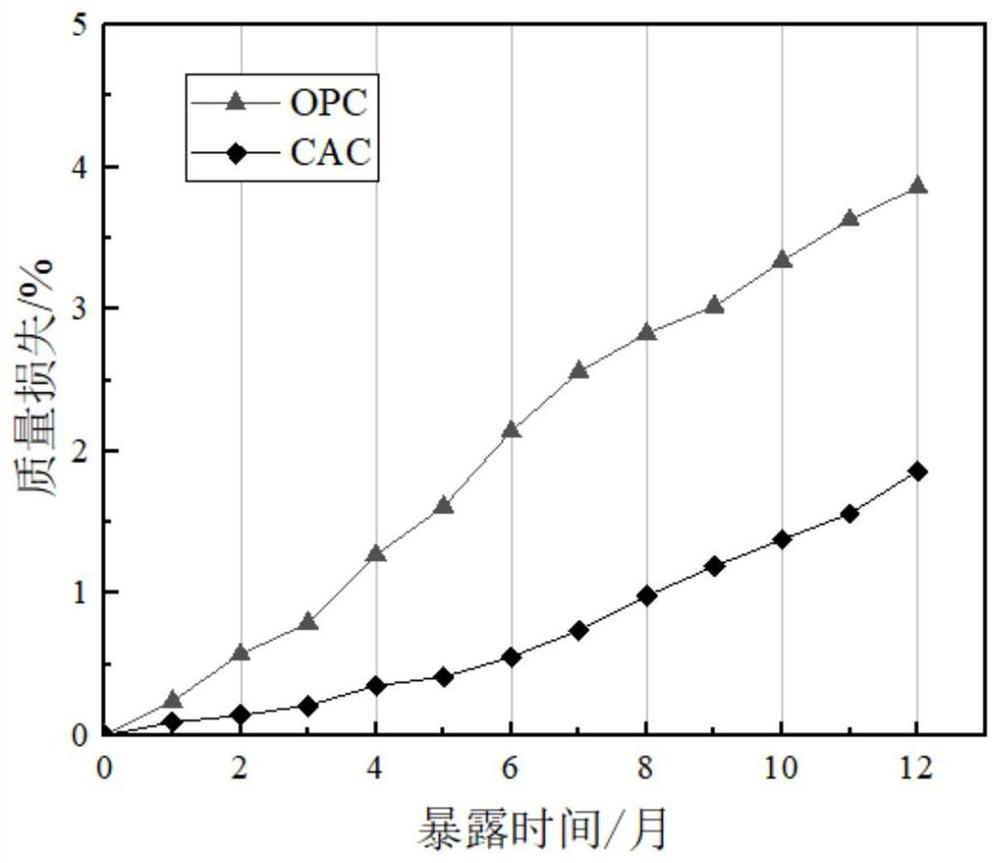

[0026] Two kinds of antibacterial corrosion mortars for the inner lining of sewage concrete pipelines were prepared respectively from ordinary Portland cement (OPC) and aluminate cement (CAC) and siliceous medium sand.

[0027] At 20°C, the uniformly stirred mortar was made into a cylindrical sample with a diameter of 60 mm and a height of 120 mm. The prepared cylindrical mortar samples were hung in the exposure box, and then placed on top of a sewage pipe with a large flow of domestic wastewater. The pH of the waste water from the sewer pipeline has been maintained at around 4 for a long time, and the surrounding concrete walls have shown obvious corrosion and deterioration. The cylindrical mortar samples were exposed on site for 12 months, and their appearance and mass loss were regularly detected during the exposure period.

[0028] After 12 months of exposure, the samples made of OPC deteriorated severely, showing obvious peeling of the surface layer; in contrast, the sam...

Embodiment 2

[0031] Table 1 shows the composition of cementitious materials and aggregate types used in five kinds of concrete for pouring sewage pipelines.

[0032] Under 20 DEG C, the concrete that has been stirred is poured the sample that grows 200mm * width 150mm * thickness 80mm, and every kind of sample is divided into 3 groups, is placed in 3 sewage pipe network manhole places respectively (this sewage pipe network is the same as embodiment 1) sewer network). After 12 months of on-site exposure, it was taken out, and its mass loss was measured with an electronic balance with an accuracy of 0.001g. The recorded results are shown in Table 2.

[0033] Table 1 Concrete formulations for sewer pipes with different cementitious materials / aggregate types

[0034] Sample serial number Composition of cementitious material aggregate type PC1 OPC100% Silica PC2 OPC100% dolomite CA1 CAC100% Silica CA2 CAC100% dolomite CA / SL1 CAC85%+15% s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| activation index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com