Electrostatic-filtering type combined dust-cleaning equipment

An electrostatic precipitator and filtering technology, which is applied in the field of electrostatic-filter composite precipitators, can solve the problems of inappropriateness, high operating costs, and large operating resistance, and achieve reduced scouring damage, large scouring wear, and large momentum. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

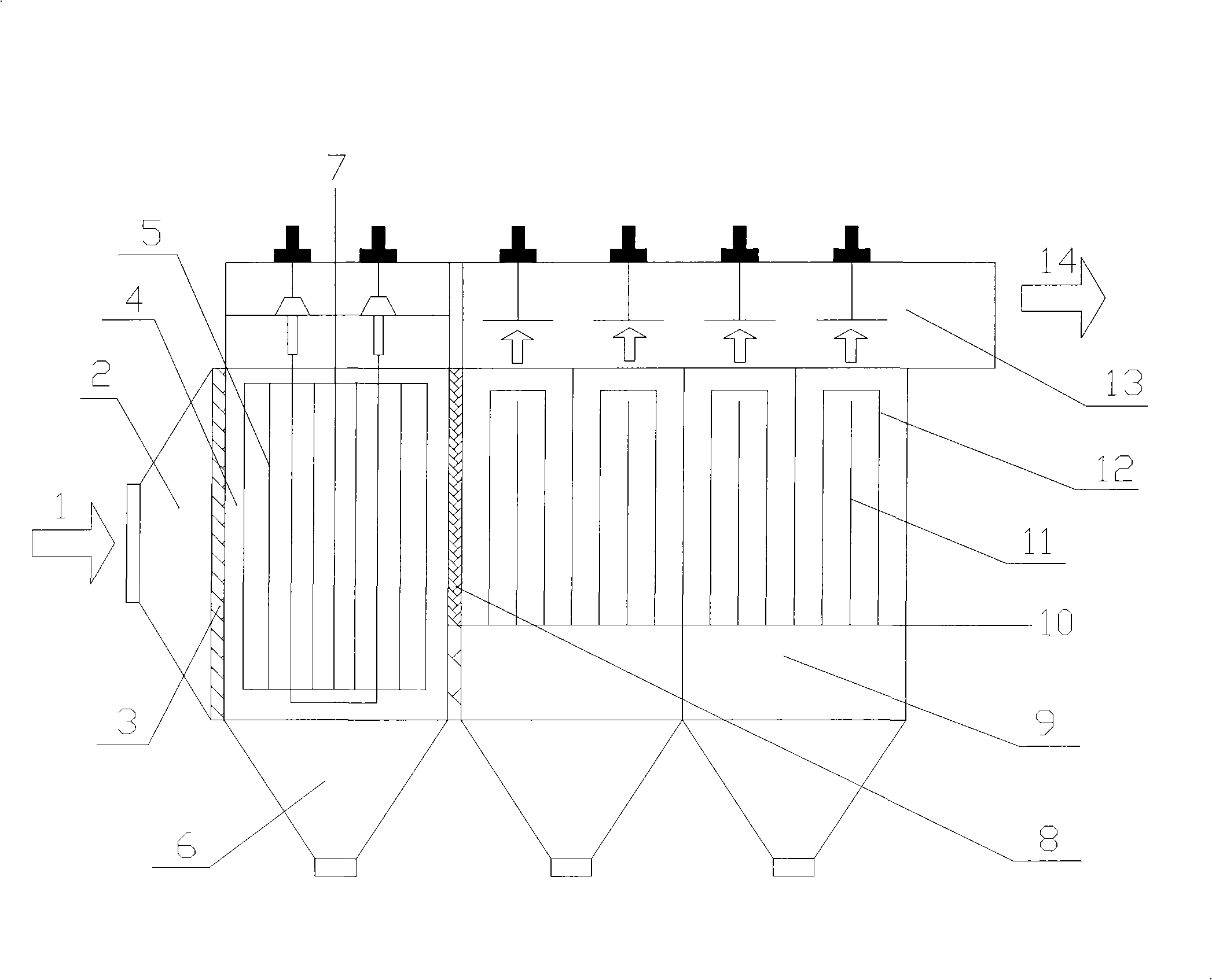

[0023] The electrostatic-filter compound dust collector organically combines the electrostatic precipitator and the bag filter, and adopts two power supply forms of negative high-voltage DC and high-voltage sinusoidal AC. The front-stage electrostatic precipitator adopts a wire-plate structure, the cathode is a discharge electrode, and the anode is a dust-collecting electrode; the back-stage bag filter is equipped with a coagulation electrode, which uses a high-voltage sinusoidal AC power supply, with a peak voltage of 10 kV and a frequency of 50 Hz. .

[0024] (1) The dust concentration at the inlet of the dust collector is 30-40g / Nm 3 ;

[0025] (2) The negative high-voltage DC power supply voltage of the electrostatic precipitator is negative 20 kV;

[0026] (3) The peak voltage of the high-voltage sinusoidal AC power supply of the bag filter is 10 kV, and the frequency is 50 Hz;

[0027] (4) Number of bag filter chambers: 4;

[0028] (5) The filter bag is coated with P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com