Anti-molten aluminum corrosion coating and preparation method thereof

A technology of corrosion coating and melting aluminum, which is applied in the field of anti-melting aluminum corrosion coating and its preparation, can solve the problems of not being able to adapt to the production conditions of aluminum-silicon plating, poor platingability of aluminum liquid, and affecting the quality of steel plates, etc., so as to reduce replacement Maintenance cost, improvement of hot corrosion resistance, effect of reducing coating peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

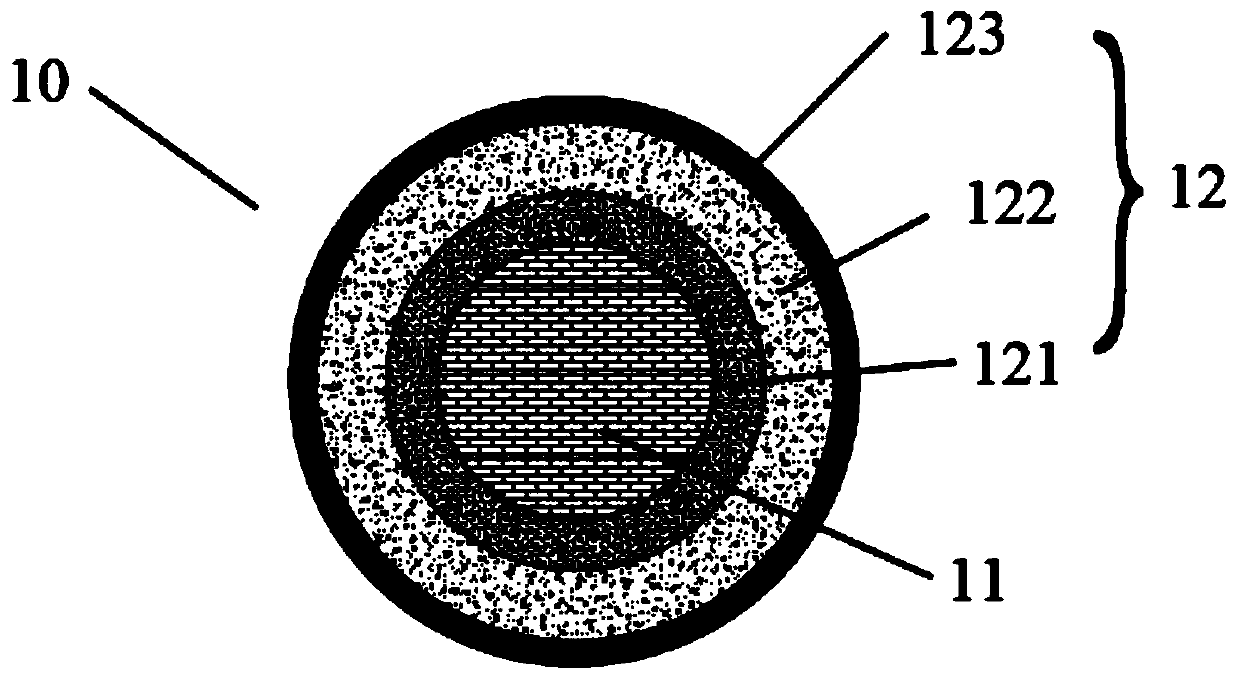

[0031] The present invention will be described in detail below in conjunction with the drawings:

[0032] Such as Figure 1-Figure 2 As shown, the molten aluminum corrosion resistant coating 12 in the embodiment of the present invention includes at least three sub-coatings, which are an alloy layer 121 coated on the surface of the substrate 11, a ceramic layer 122 coated on the surface of the alloy layer 121, and The sealing layer 123 is coated on the surface of the ceramic layer 122; the base 11 is a roll for aluminizing wire. After coating the anti-melting aluminum corrosion coating 12 on the aluminum-plated wire roller, it can be applied to the hot-dip aluminum-silicon production line, with high temperature resistance, thermal shock resistance, and excellent resistance to aluminum adhesion and corrosion resistance to molten aluminum , So as to produce high-quality aluminized silicon steel sheet.

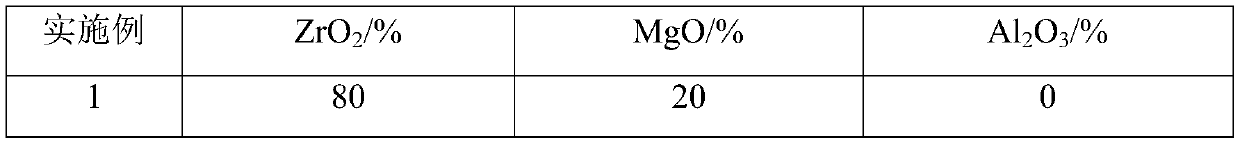

[0033] The alloy layer 121 consists of the following components by weight percent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com