Anti-melting aluminum corrosion roll

A technology of corroding rollers and melting aluminum, applied in coating, metal material coating process, pressure inorganic powder coating, etc. problems, to achieve the effect of reducing replacement and maintenance costs, reducing coating peeling, and improving heat resistance and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

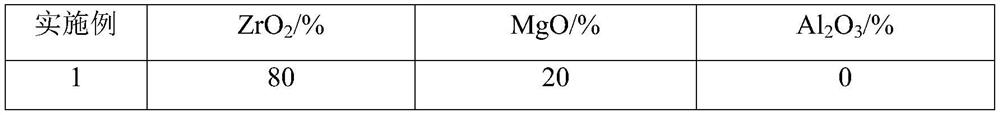

Examples

Embodiment Construction

[0031] The present invention is described in detail below in conjunction with accompanying drawing:

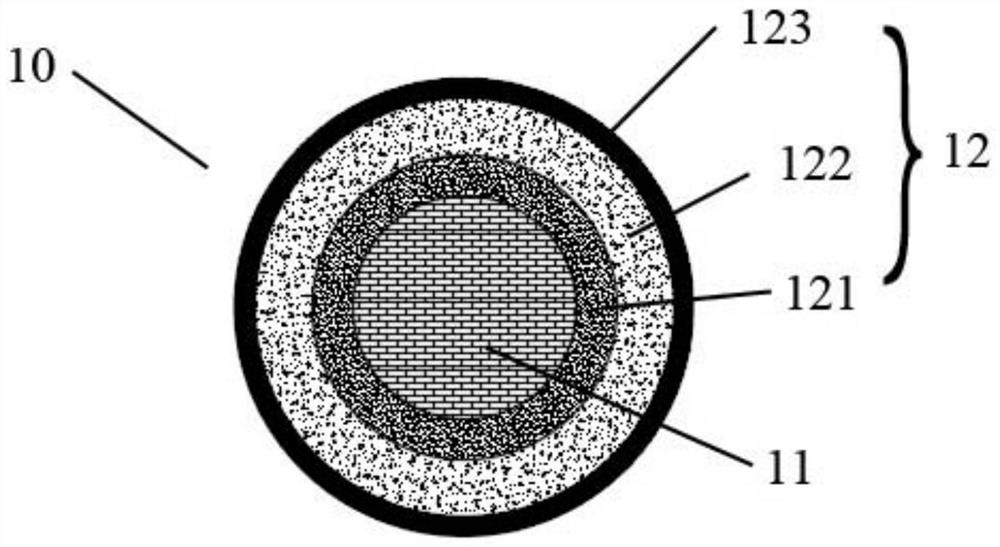

[0032] Anti-melting aluminum corrosion roll 10 such as figure 1 As shown, it includes a substrate 11 and an anti-melting aluminum corrosion coating 12 coated on the surface of the substrate; the substrate 11 is a roller for an aluminum plating line. Such as figure 2 As shown, the anti-melting aluminum corrosion coating 12 includes at least three layers of sub-coatings, which are respectively an alloy layer 121 coated on the surface of the substrate 11, a ceramic layer 122 coated on the surface of the alloy layer 121, and a ceramic layer 122 coated on the surface of the ceramic layer 122. The sealing layer 123 on the surface. The anti-melting aluminum corrosion roller in the embodiment of the present invention can be applied to the hot-dip aluminum-silicon production line, has high temperature resistance, thermal shock resistance, and excellent resistance to sticking aluminu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com