Ferritic stainless steel excellent in high-temperature wear resistance, manufacturing method of ferritic stainless steel plate, exhaust component, high-temperature sliding component, and turbocharger component

A sliding part, stainless steel technology, used in turbocharger parts, converters, exhaust manifolds, can solve the problem of cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

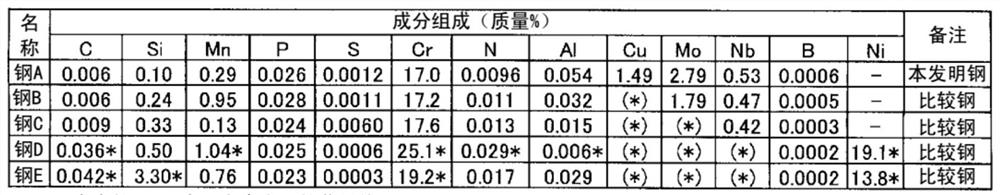

[0044] Embodiments of the ferritic stainless steel plate excellent in high temperature wear resistance suitable for the present invention will be described in detail below.

[0045] [Element]

[0046] First, the composition range of steel will be described. The % related to the content of components means % by mass unless otherwise specified.

[0047] C is an austenite-forming element, and when an austenite phase is formed during high-temperature use, abnormal oxidation occurs and the high-temperature wear resistance significantly decreases. In addition, if carbides are formed in the ferrite phase, the high-temperature strength will decrease, so 0.02% is set as the upper limit. On the other hand, an excessive reduction leads to an increase in cost, so 0.003% is set as the lower limit. Furthermore, considering the production cost, the lower limit is preferably 0.005%. Furthermore, in consideration of toughness, the upper limit is preferably 0.010%.

[0048] Si is sometimes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com