Combined rubber vibration isolator for floating slab track

A rubber vibration isolator and combined technology, applied in the field of vibration reduction and noise reduction, can solve the problems of increasing maintenance costs, achieve the effects of reducing replacement and maintenance costs, maintaining vibration reduction performance, and convenient and quick post-maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

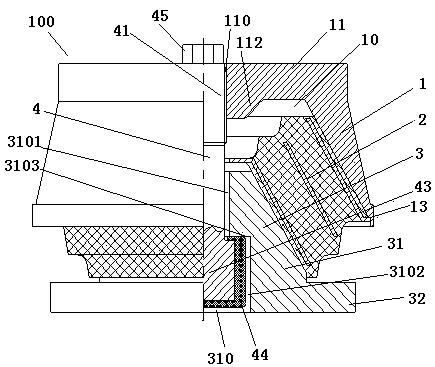

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

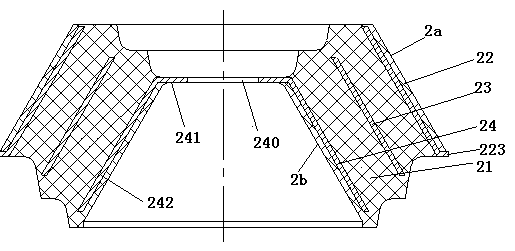

[0026] figure 1 A schematic cross-sectional structure diagram of an embodiment of a combined rubber vibration isolator for a floating slab track according to the present invention is shown. figure 2 A schematic cross-sectional view of an elastic rubber member according to an embodiment of the present invention is shown. See figure 1 and figure 2 According to an embodiment of the present invention, a combined rubber vibration isolator 100 for a floating slab track is composed of an upper metal part 1 , a rubber elastic part 2 , a lower metal part 3 and a locking element 4 .

[0027] The rubber elastic member 2 is an independent component, which can provide a certain radial stiffness while satisfying the vertical stiffness. The rubber elastic part 2 is a hollow truncated conical structure. The rubber elastic part 2 has a conical outer peripheral surface 2a and a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com