Differential vibration reduction pad block

A vibration-damping pad, differential technology, applied in the direction of spring, transformer/reactor installation/support/suspension, transformer/inductor noise damping, etc. And the weight of the winding is not equal, to achieve the effect of simple structure and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

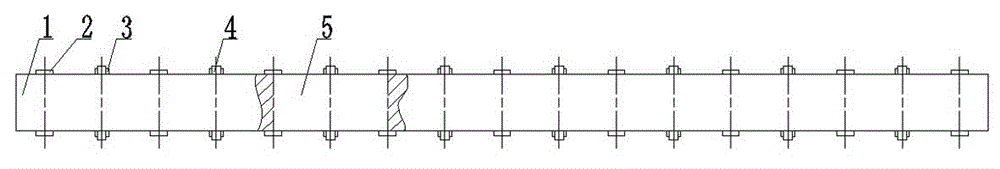

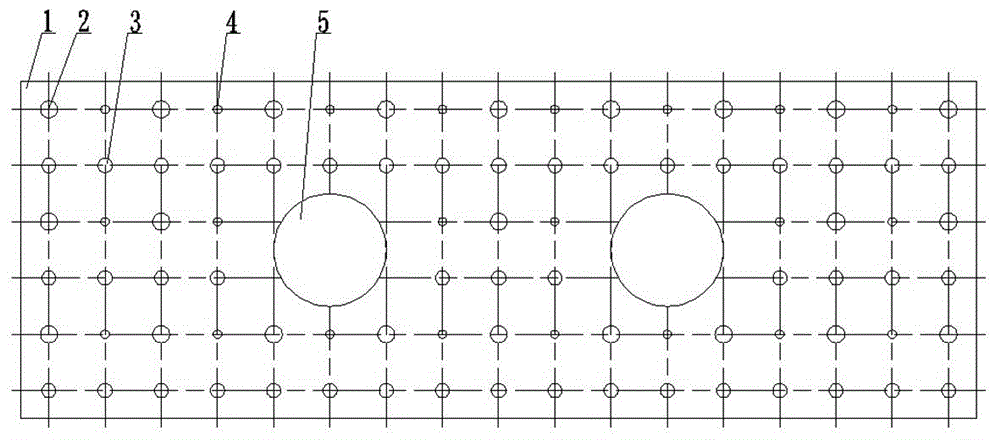

[0017] figure 1 The shown differential damping pad is a rubbery rectangular plate 1 with alternate positioning holes 5 along the midline of the length of the plate 1 . The structural improvement of the present invention is mainly reflected in the fact that the upper and lower surfaces of the plate 1 are provided with protruding points arranged alternately, in different heights, and in different sizes. This embodiment is used for vibration reduction of non-power oil-immersed amorphous transformers. The iron core of this series of transformers usually weighs 100-1200kg. Because the weight is not too large, the thickness of the matching plate 1 is set at 15-25mm. The focus is on The upper and lower surfaces of the plate 1 are designed with vibration-damping structures, that is, bumps of different positions and sizes are designed on the up...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com