Damping material

A technology of vibration-damping materials and vibrating bodies, which is applied in the field of vibration-damping materials and can solve the problems of insufficient lightness and lightness of vibration-damping plates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

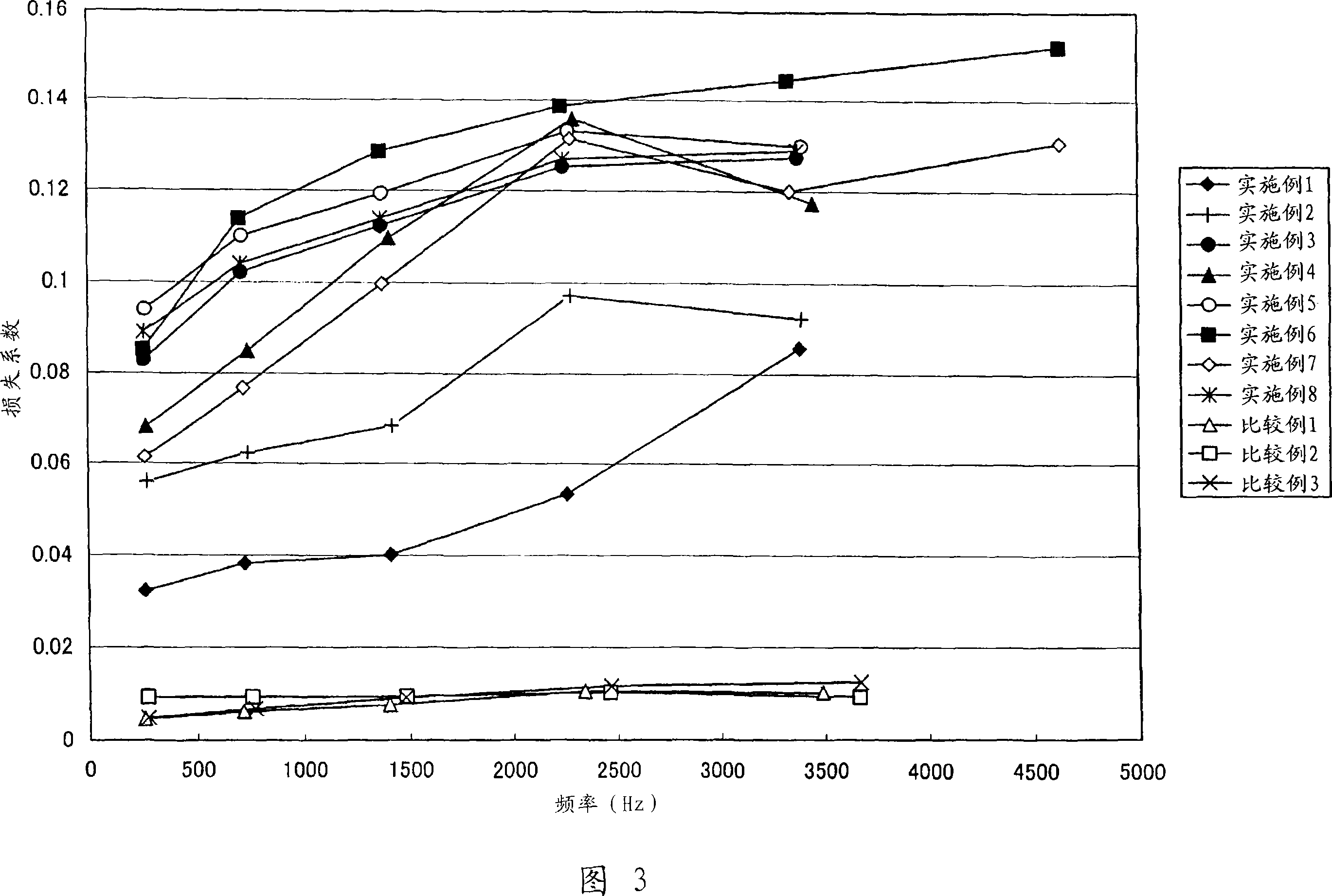

Embodiment 1

[0073]Mix the following ingredients evenly and filter to make adhesive latex, water-acrylic adhesive latex (manufactured by DAINIPPON INK AND CHEMICALS, INCORPORATED) trade name: Boncoat 350 (VONCOAT 350) Acrylic adhesive component (resin component): 50% by weight] 90 parts by weight, water-polyurethane adhesive latex [Dainippon Ink and Chemicals (DAINIPPON INK AND CHEMICALS, INCORPORATED) product name: Hidlan HW-930 ( HYDRAN HW-930), polyurethane-based adhesive component (resin component): 50% by weight] 10 parts by weight, epoxy-based crosslinking agent (Dainippon インキキキキキロスタル (DAINIPPON INK AND CHEMICALS, INCORPORATED) trade name: CR -5L) 3 parts by weight, ammonium chloride type foaming agent (Dainippon インキ chemical company (DAINIPPON INK AND CHEMICALS, INCORPORATED) manufacturer trade name: F-1) 5 parts by weight, polysiloxane type foam stabilizer (Dainippon INK AND CHEMICALS, INCORPORATED) DAINIPPON INK AND CHEMICALS, INCORPORATED (DAINIPPON INK AND CHEMICALS, INCORPORATE...

Embodiment 2

[0079] Use 21 parts by weight of azodicarbonamide instead of 14 parts by weight, replace the thickness of the foamable resin board with 2.6 mm for 1.3 mm, and irradiate electrons with an accelerating voltage of 500 kV and 3.8 Mrad instead of an accelerating voltage of 800 kV and 2.4 Mrad. ray, and the same method as in Example 1 was used to obtain a thermoplastic resin foamed plate. Among them, the thickness of the thermoplastic resin foam board is 8.6mm and the density is 0.033g / cm 3 . The Young's modulus of the thermoplastic resin foam board was 1.40 MPa. Furthermore, the foamed adhesive layer produced in the same manner as in Example 1 was laminated and integrated on one side of the above-mentioned thermoplastic resin foam board in the same manner as in Example 1 to obtain a vibration-damping material with a thickness of 10.5 mm. .

Embodiment 3

[0081] The following components were supplied to an extruder, melted and kneaded, and extruded to obtain a foamable resin plate with a thickness of 1.2 mm. Polypropylene-based resin composed of 45 parts by weight of ethylene-propylene random copolymer (trade name: XK0235 manufactured by Chisso Corporation) and 15 parts by weight of isotactic homopolypropylene (trade name: SH152 manufactured by Idemitsu Corporation), linear Low-density polyethylene (trade name: 0238CN manufactured by Idemitsu Corporation) 40 parts by weight, azodicarbonamide 6.8 parts by weight, crosslinking agent (trade name: TND-23H manufactured by Kyoei Chemical Co., Ltd.) 3 parts by weight, antioxidant A ( Asahi Denka trade name: ADEKASTAB AO-60 (ADEKASTAB AO-60)) 1 part by weight, antioxidant B (ADEKASTAB CDA-1 (ADEKASTAB CDA-1)) 0.5 part by weight, and antioxidant C (trade name manufactured by Ouchi Shinko Chemical Co., Ltd.: NOCRAC400S (NOCRAC400S)) 0.5 parts by weight.

[0082] Both surfaces of the obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Young's modulus | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

| Melting temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com