System and method for high-pressure start-up of reduction furnace

A high-voltage startup and reduction furnace technology, applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., can solve the problem of applying high voltage to the silicon core, and achieve the effect of saving startup time and saving replacement and maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

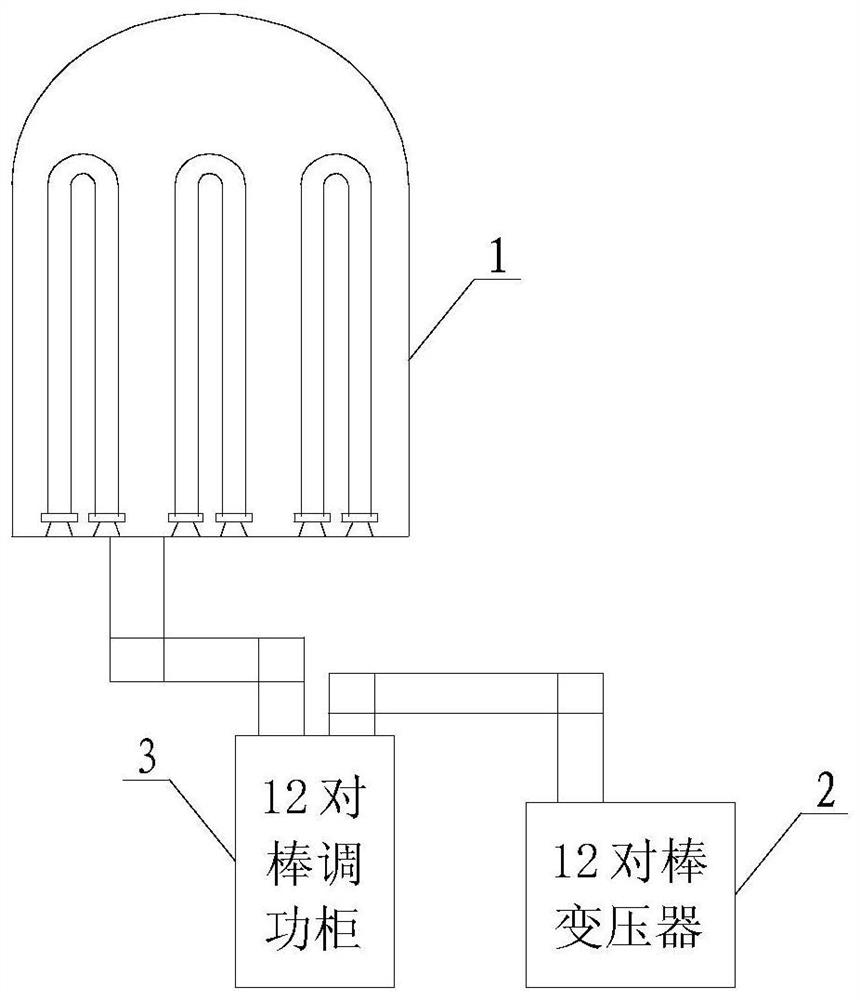

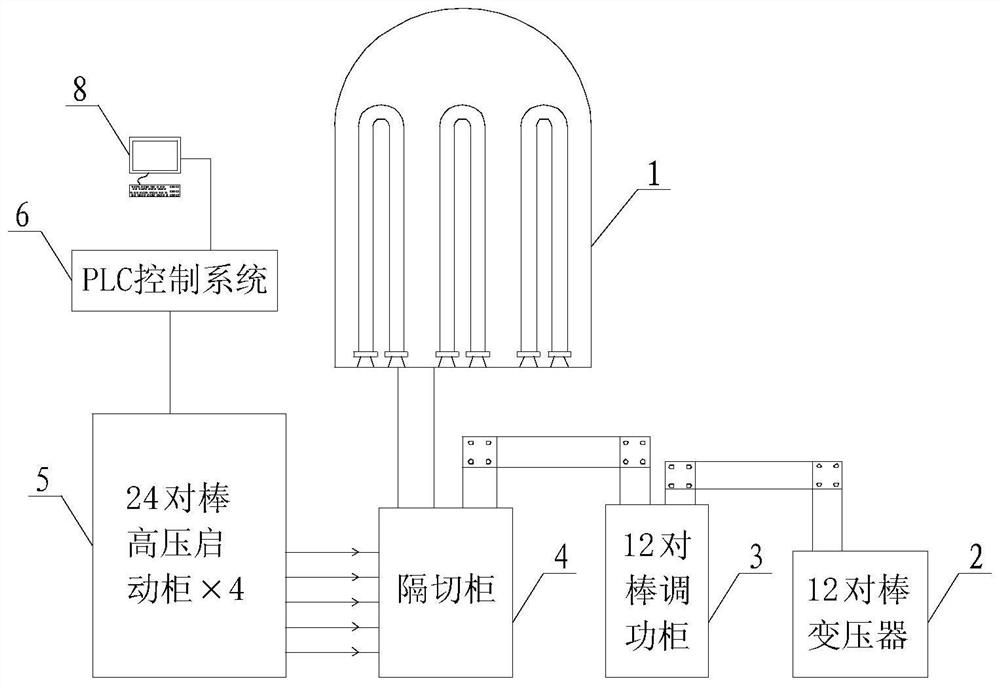

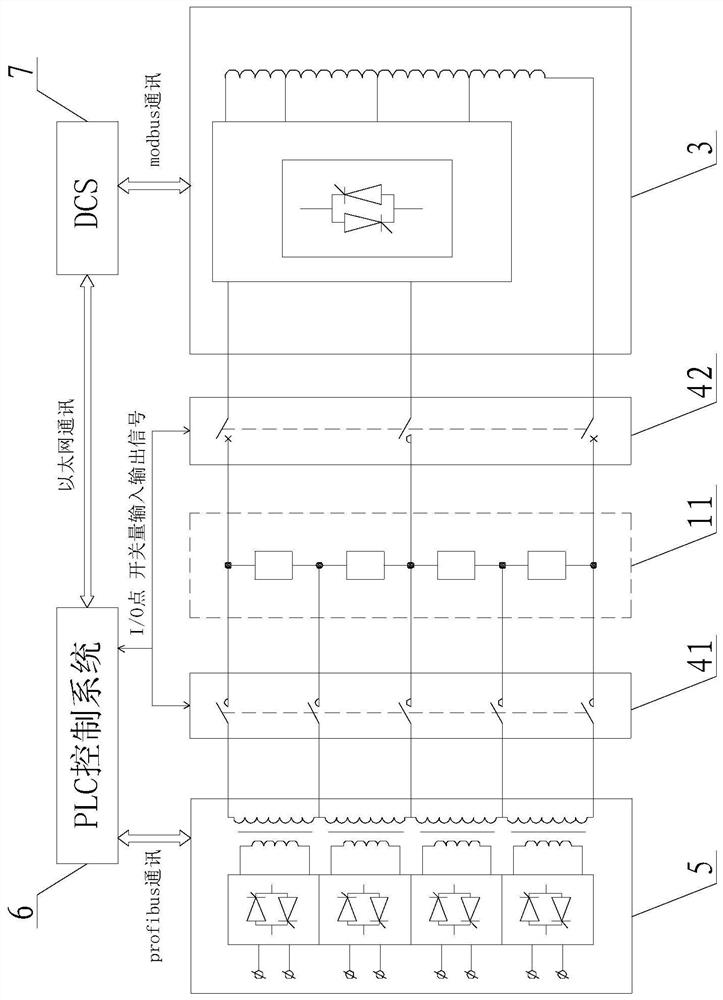

[0064] Such as figure 2 As shown, this embodiment provides a high-voltage start-up system for a reduction furnace, which includes 12 pairs of rod power-adjusting cabinets 3, cut-off cabinets 4 and 24 pairs of rod-high-voltage start-up systems, and the 12 pairs of rod power-adjusting cabinets 3 pass through the cut-off cabinets. 4 is connected to the silicon core of the reduction furnace 1, and the 24 pairs of rod high-voltage starting systems are also connected to the silicon core of the reduction furnace 1 through the partition cabinet 4; After the phase silicon core is connected, it is used to apply a breakdown voltage to the single-phase silicon core until the single-phase silicon core breaks down. Within a set time (preferably within 3S), the single-phase silicon core is connected to the single-phase silicon core under the switching of the partition cabinet 4, and a preset voltage is applied to the single-phase silicon core to maintain the conduction of the silicon core; ...

Embodiment 2

[0082] This embodiment provides a high-voltage start-up method applied to the high-voltage start-up system of the reduction furnace. The high-voltage start-up system of the reduction furnace includes 12 pairs of rod power adjustment cabinets, partition cabinets and 24 pairs of rod high-voltage start-up systems. The 12 pairs of rod regulators The power cabinet is connected to the silicon core of the reduction furnace through the partition cabinet, and the 24-pair high-voltage start-up system is also connected to the silicon core of the reduction furnace through the partition cabinet.

Embodiment approach

[0083] Such as Figure 4 As shown, as an embodiment of the present invention, the high-voltage starting method includes the following steps S101 to S104:

[0084] S101. Connect the 24 pairs of rod high-voltage starting system to a single-phase silicon core under the switch of the partition cabinet, and apply a breakdown voltage to the single-phase silicon core through the 24 pairs of rod high-voltage starting system until the single-phase silicon core breaks down. Put on;

[0085] S102. Within the preset time after the breakdown of the single-phase silicon core, the 12 pairs of rod power regulating cabinets are connected to the single-phase silicon core under the switching of the partition cabinet, and the 12 pairs of rod power regulating cabinets are connected to the single-phase silicon core. The single-phase silicon core is loaded with a preset voltage to maintain the conduction of the silicon core, wherein the preset time is preferably within 3s;

[0086] S103. Judging w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com