Cooling system of oil-immersed self-cooling transformer

A transformer, oil-immersed technology, applied in the field of transformer cooling, can solve problems such as poor heat dissipation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

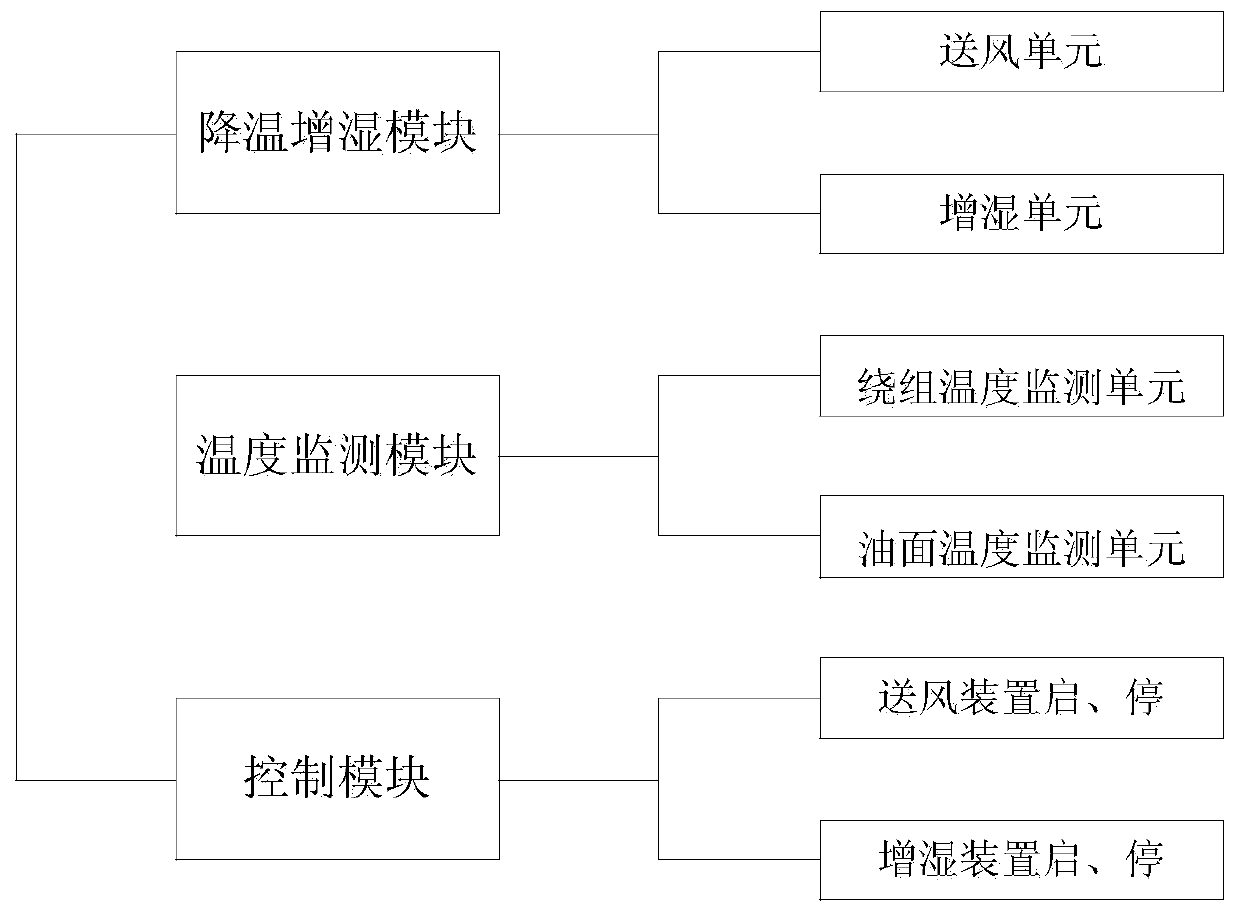

[0029] Such as figure 1 and figure 2 An oil-immersed self-cooling transformer cooling system is shown, which is characterized in that it includes a winding temperature monitoring unit, an oil surface temperature monitoring unit, a humidification unit, an air supply unit, and a control module. The control module is based on the winding temperature monitoring unit. The signal controls the start and stop of the humidification unit, and the control module controls the start and stop of the air supply unit according to the signal of the oil surface temperature monitoring unit. The winding temperature monitoring unit and the oil surface temperature monitoring unit are respectively the winding temperature controller and the oil surface temperature controller of the oil-immersed self-cooling transformer.

[0030] Preferably, the control module includes two groups of control units, and the two groups of control units respectively control the start and stop of the humidification unit ...

Embodiment 2

[0032] Such as figure 1 and figure 2 A kind of oil-immersed self-cooling transformer cooling system shown, on the basis of embodiment 1:

[0033] The start and stop of the humidifying unit respectively correspond to the temperatures A and B monitored by the winding temperature monitoring unit;

[0034] The start and stop of the air supply unit correspond to the temperatures C and D monitored by the oil surface temperature monitoring unit respectively;

[0035] Among them, A>C>B>D.

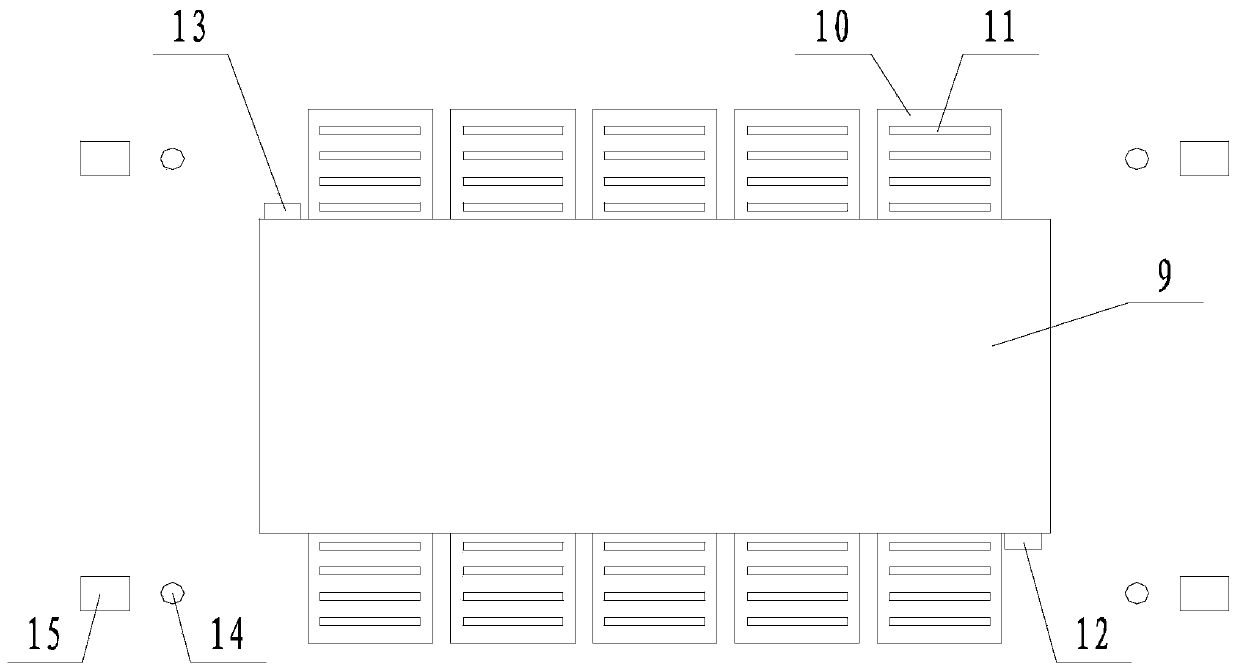

[0036] A number of humidification units and air supply units are arranged around the transformer, and each air supply unit is matched with a humidification unit; the air supply unit is located on the side of the corresponding humidification unit away from the heat sink of the transformer. The connection line between each air supply unit and the corresponding humidification unit is perpendicular to the connection line between the cooling fins.

[0037] In this embodiment, when the temperature m...

Embodiment 3

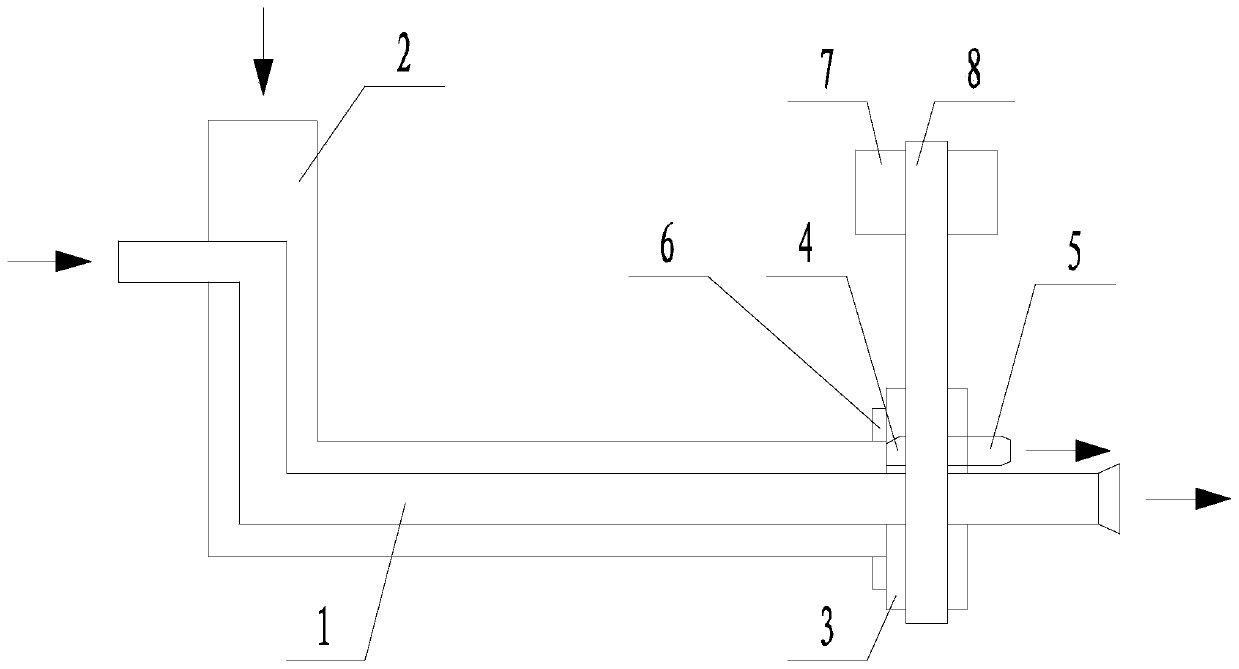

[0047] Such as Figure 1 to Figure 3 An oil-immersed self-cooling transformer cooling system shown is based on any of the above-mentioned embodiments: the humidification unit includes a water inlet pipe 1, and the air supply unit includes an air inlet pipe 2, and the water inlet pipe 1 is from The side wall of the intake pipe 2 is inserted into the intake pipe 2, and passes through the outlet end of the intake pipe 2, and also includes a turntable 3 that is sleeved on the water inlet pipe 1, and the turntable 3 is closed to the outlet end of the intake pipe 2 , the turntable 3 is provided with a channel 4 communicating with the air intake pipe 2 , and also includes an air gathering port 5 communicating with the channel 4 . The end of the intake pipe 2 adjacent to the turntable 3 is fixedly sleeved with a sealing ring 6 . The rotation connection between the rotating disk 3 and the water inlet pipe 1 is realized through a bearing. It also includes a driving mechanism for drivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com