A gantry type automatic fillet welding vehicle

A rack-type and automatic technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problem of welding seam repair workload and plate frame correction workload, difficult to control the welding deformation of flat plate frame, and the kinetic energy of crane equipment. problems such as large interference, to achieve the effect of reducing human influence factors, stable welding process parameters, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

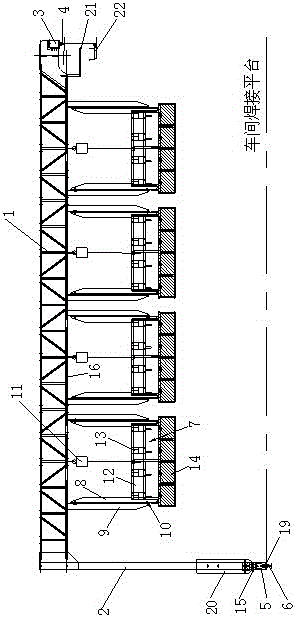

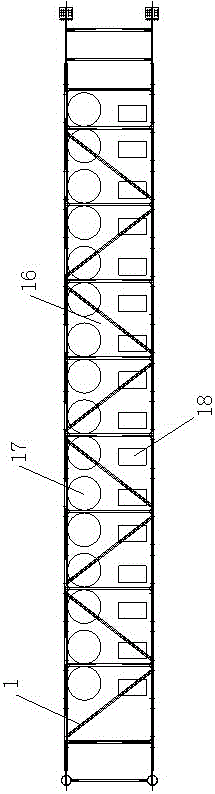

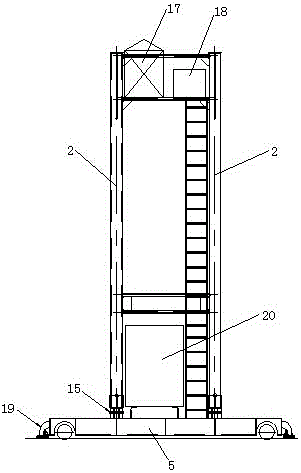

[0034] Such as Figure 1-2 As shown, the gantry type automatic fillet welding vehicle of this embodiment includes a gantry traveling mechanism, several welding trolley frame lifting mechanisms, an electrical control system, a flexible drag chain power system, a CO 2 Gas shielded welding equipment, the lifting mechanism of the welding trolley frame is suspended and arranged under the traveling mechanism of the gantry, and the CO 2 The welding host 18 of the gas shielded welding equipment is set on the gantry traveling mechanism, CO 2 The welding head 13 of the gas shielded welding equipment is set on the lifting mechanism of the welding trolley frame, and the electrical control system controls the gantry traveling mechanism, CO 2 Gas shielded welding equipment, the operation of the lifting mechanism of the welding trolley frame, the flexible drag chain power system supplies power for the electrical control system, and provides power for the CO 2 Gas shielded welding equipment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com