A CNC three-axis positioner and a CNC six-axis automatic welding unit

A positioner, axial technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., to achieve the effect of improving clamping efficiency, improving welding quality, and eliminating overhead welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

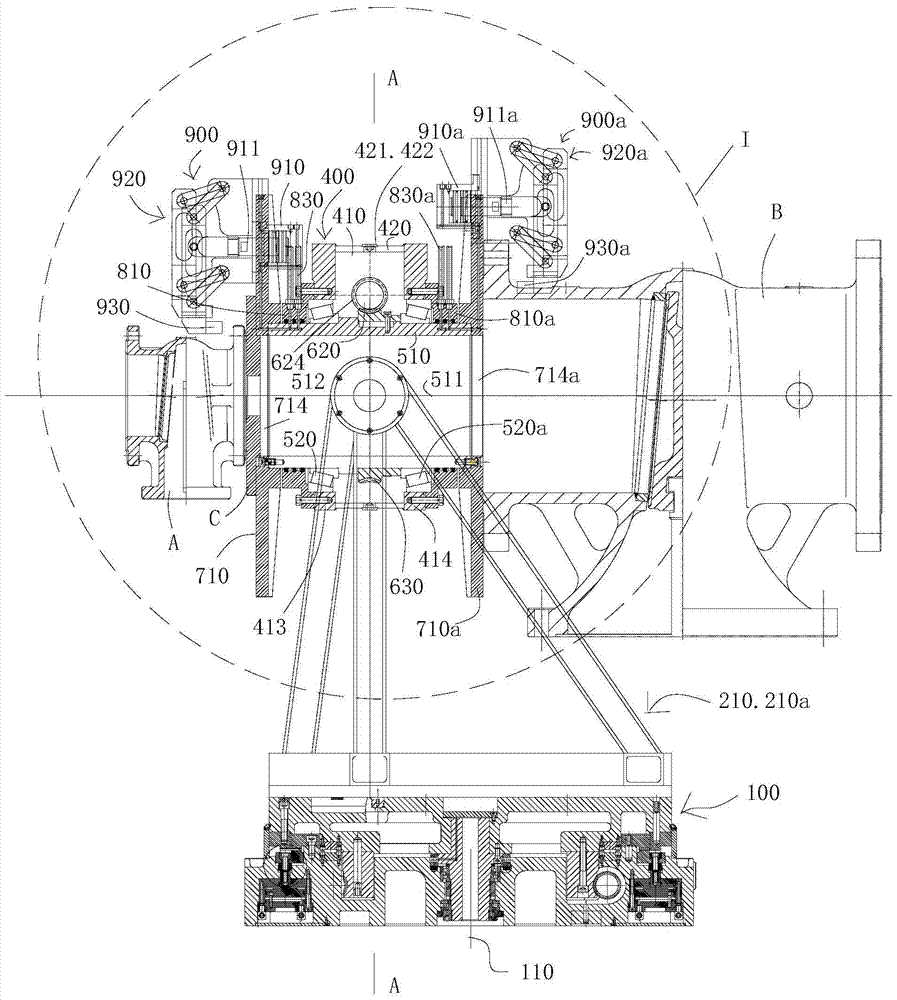

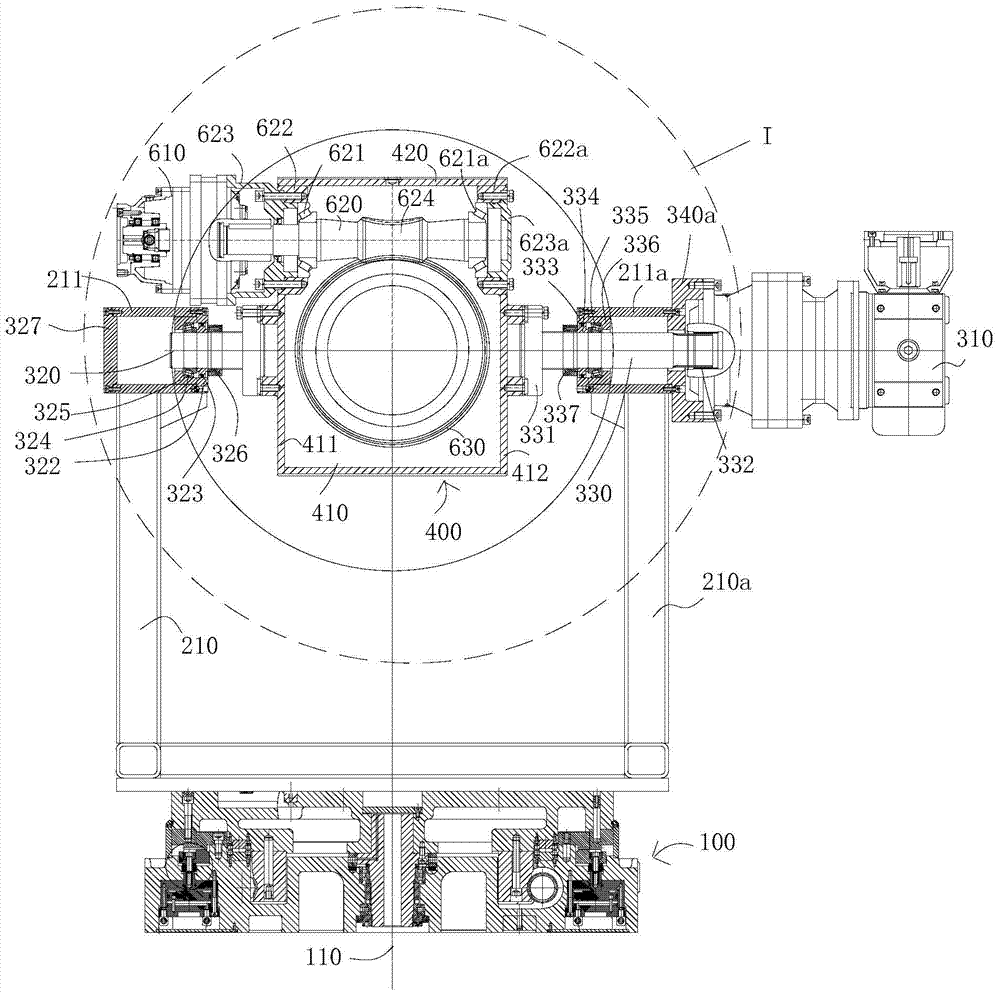

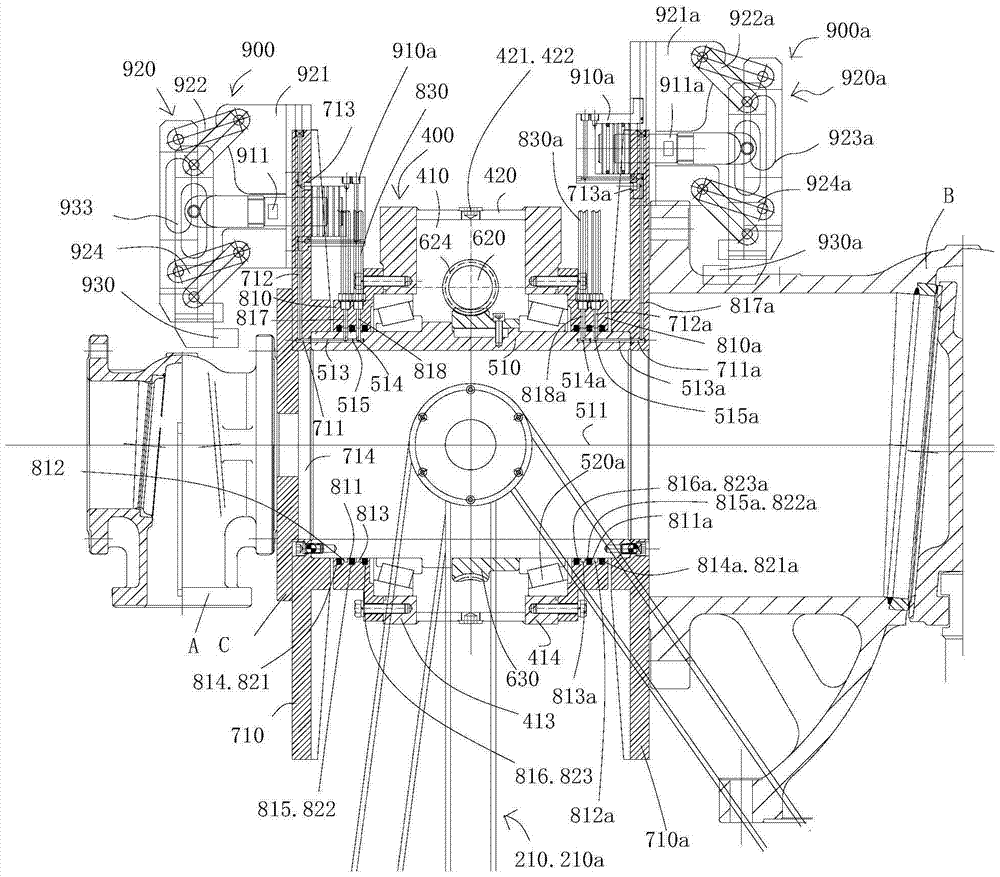

[0041] see Figure 1 to Figure 5 , the CNC three-axis positioner shown in the figure includes a turntable 100 installed on the foundation. The structure of the turntable 100 is no different from that of the existing turntable, and will not be described here. The central axis 110 of the turntable 100 constitutes a first axis, and the turntable 100 is driven to rotate around the first axis by a turntable drive mechanism (not shown in the figure); institutions etc.

[0042] On the turntable 100, a left side support 210 and a right side support 210a are installed at intervals, and the left side support 210 and the right side support 210a rotate synchronously with the turntable 100, and one is respectively fixed on the top of the left side support 210 and the right side support 210a. The left side bushing 211 and the right side bushing 211a.

[0043]The whole turntable drive mechanism includes a servo motor 310, shaft 320, spline shaft 330, wherein the servo motor 310 is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com