Automatic robot welding and cleaning production line for C-GIS

An automatic welding and robot technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of low work efficiency, high labor intensity of workers, inability to automatically complete welding and cleaning at one time, and achieve saving time, avoid vertical welding and overhead welding, and ensure the effect of welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the purpose, technical solution and advantages of the present invention clearer, the following will further describe the implementation of the present invention in detail in conjunction with the accompanying drawings.

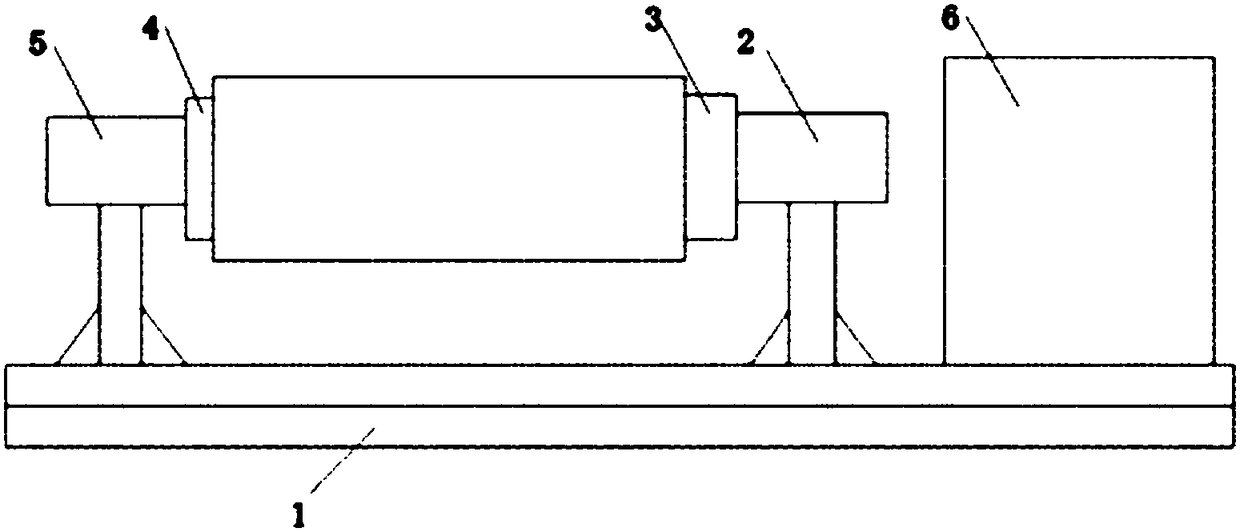

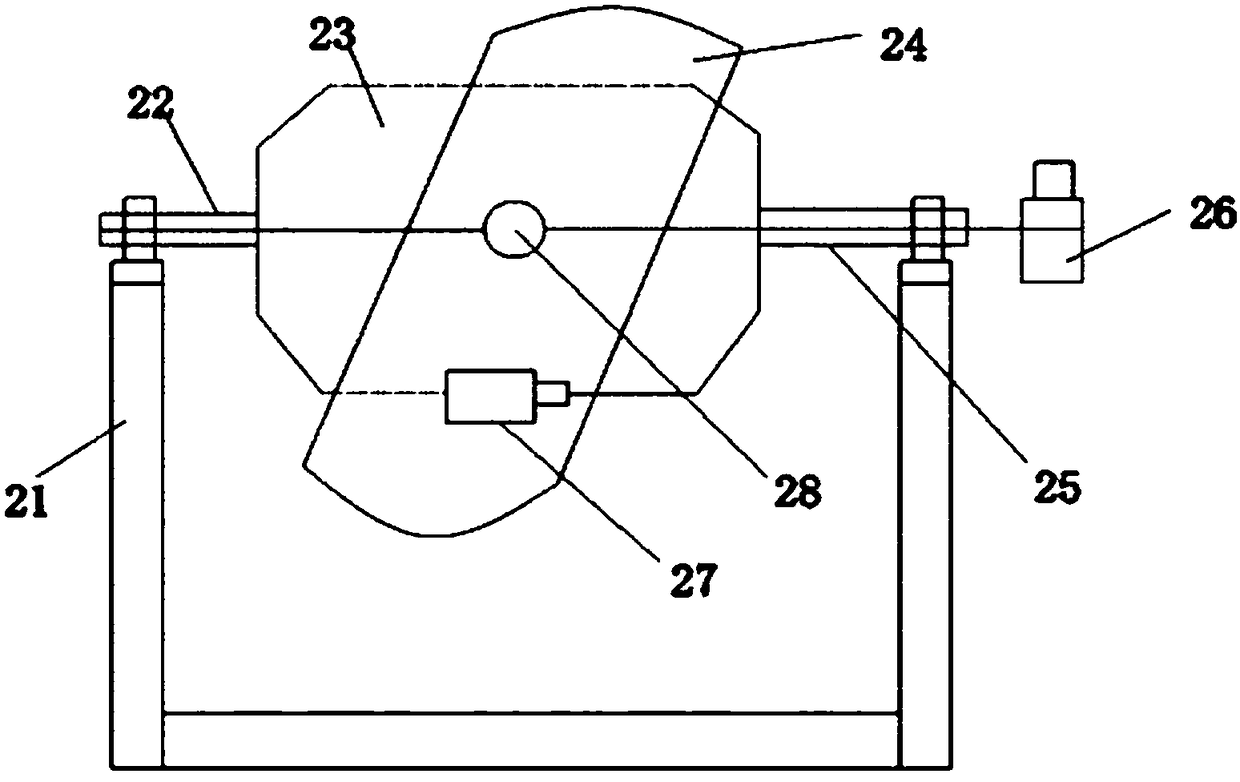

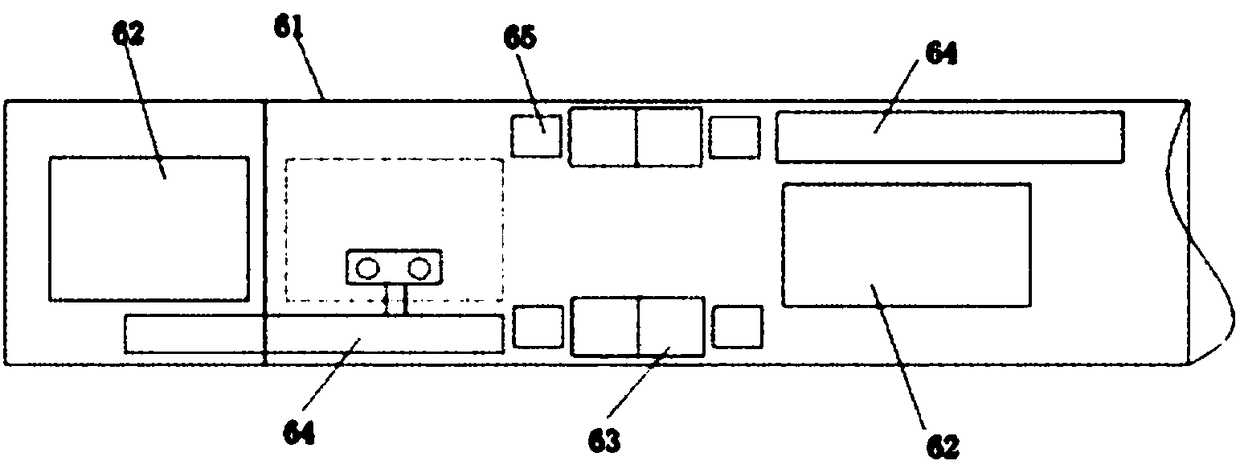

[0014] like figure 1 As shown, an inflatable cabinet robot automatic welding and cleaning production line mainly includes a base assembly 1, a positioner assembly 2, a main turntable 3, an auxiliary turntable 4, a support shaft assembly 5 and a cleaning assembly 6, a positioner assembly 2 and a support shaft The assembly 5 is fastened together with the base assembly 1 by bolts, and the positioner assembly 2 includes a chassis 21, a first drive shaft 22, a lower turntable 23, an upper turntable 24, a second drive shaft 25, a first reducer 26 and a second turntable. 2. Speed reducer 27, cleaning assembly 6 mainly includes cleaning machine table 61, carrier 62, cleaning unit 63, transfer unit 64 and detection unit 65, in two sets of separ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com