Construction method of steel structure beam-column connecting joint

A beam-column connection and construction method technology, which is applied to building structures, buildings, etc., can solve the problems such as the accumulation of welding damage to the flange plate, the penetration of butt welds on the upper flange plate, and the difficulty of welding, etc. Achieve the effect of benefiting seismic energy dissipation, reducing penetration welds, and reducing construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

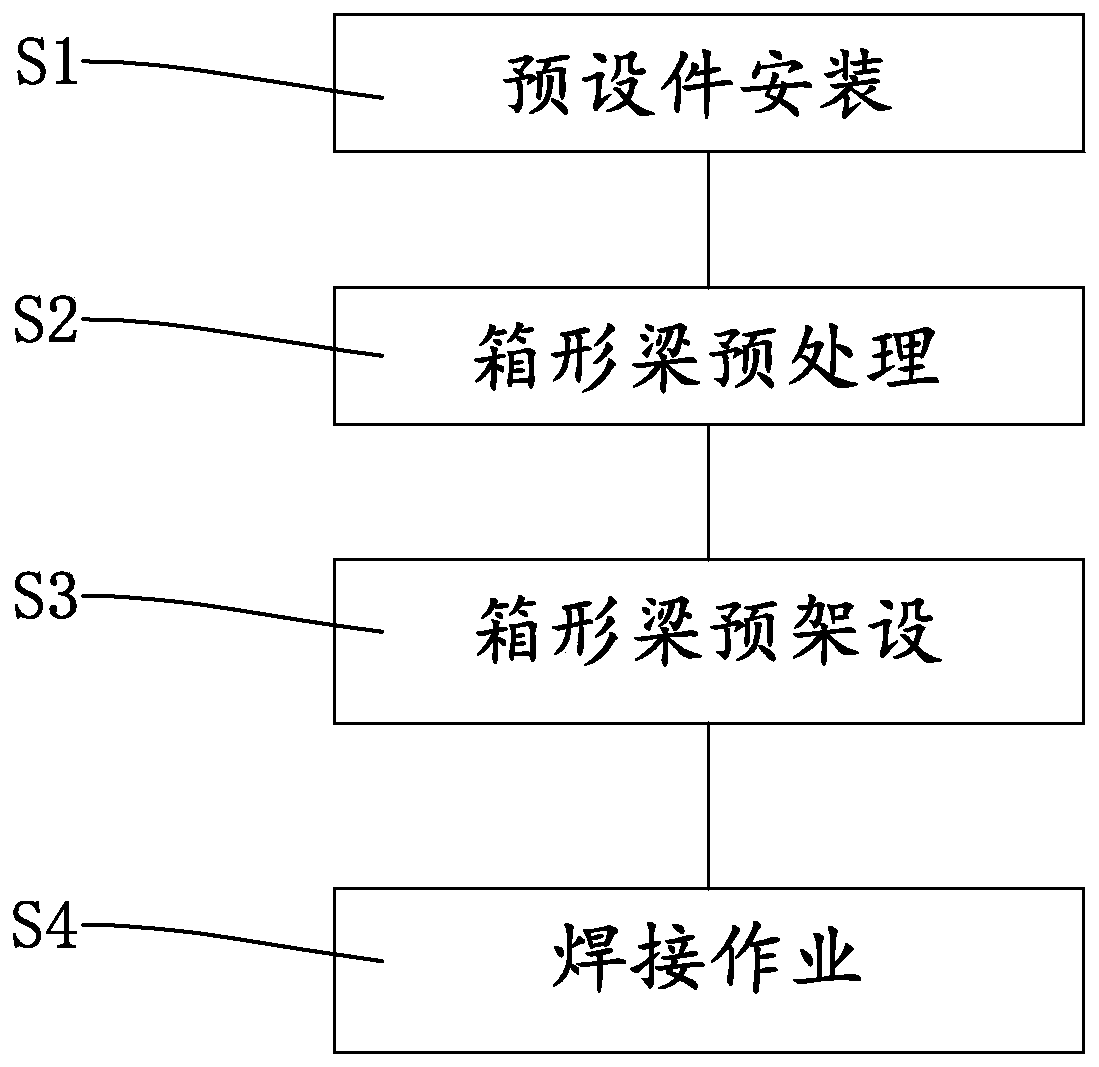

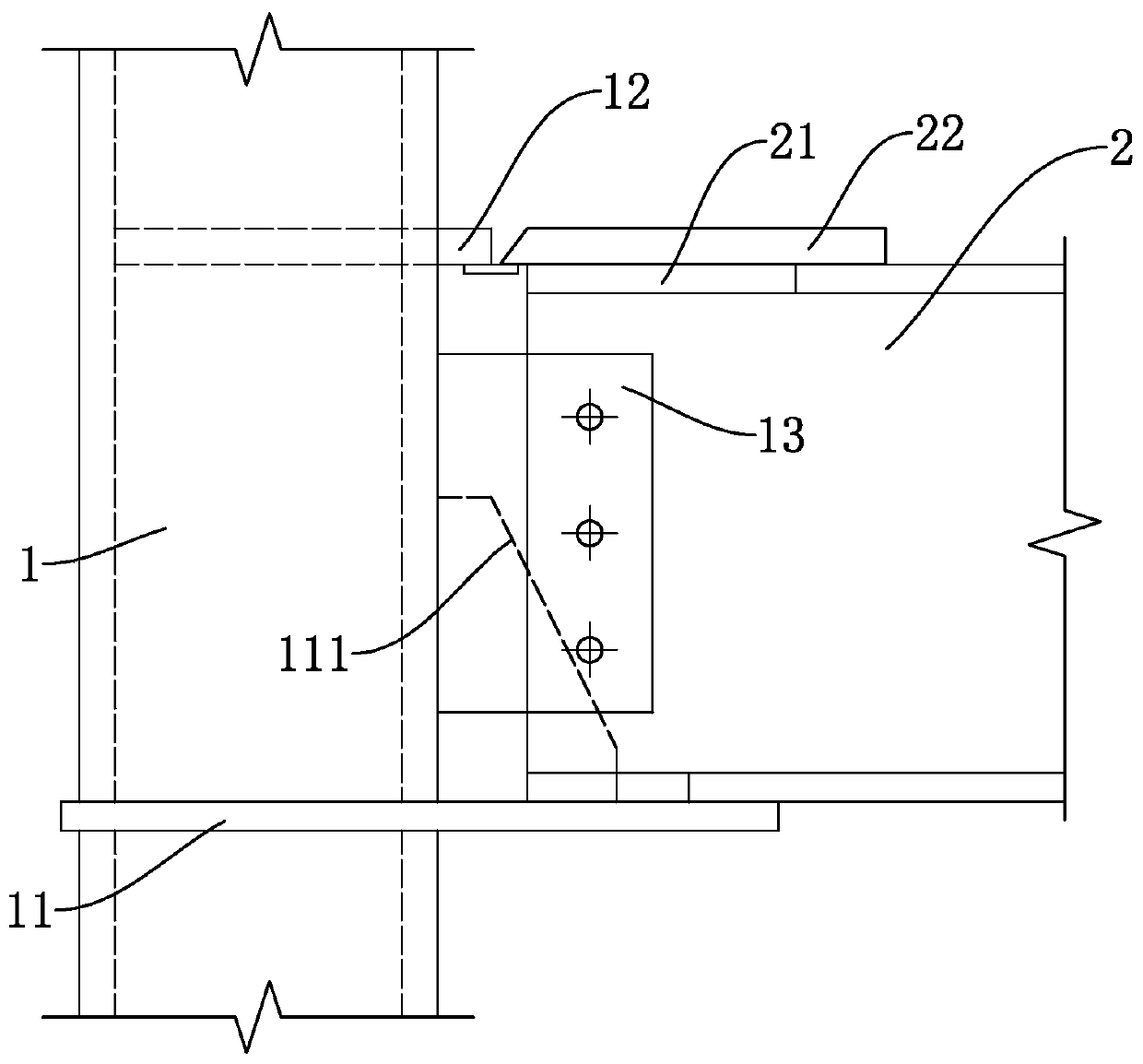

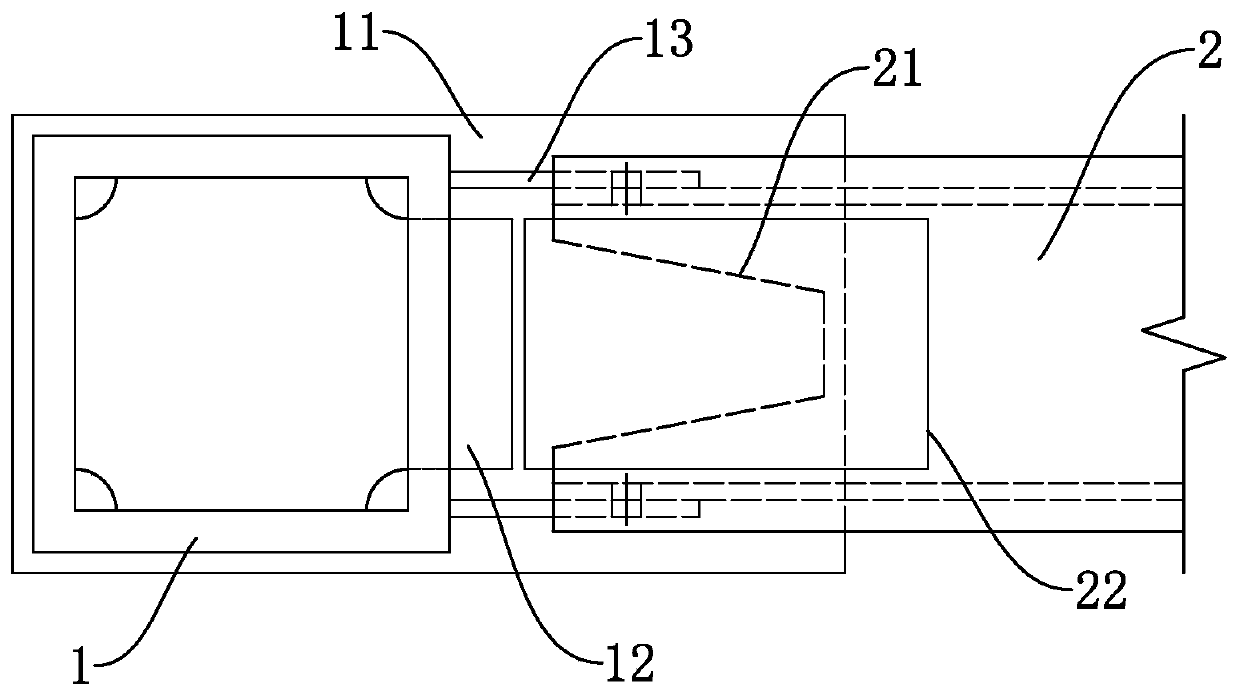

[0036] see figure 1 and figure 2 , a construction method of a steel structure beam-column connection node, comprising the steps of:

[0037] S1. Preset the receiving parts. The receiving parts are preset at the connection between the two steel columns 1 and the box girder 2. The receiving part is the first lower transverse partition 11, and the first lower transverse partition 11 is arranged horizontally. The length of the lower diaphragm 11 along the width direction of the box girder 2 is greater than the width of the lower flange of the box girder 2 , and the first lower diaphragm 11 is welded on the steel column 1 . Optionally, the first lower diaphragm 11 is pre-embedded in the steel column 1 during the production of the steel column 1 , and the side of the first lower diaphragm 11 close to the box girder 2 passes through the steel column 1 .

[0038] S1.1. In order to ensure the load-bearing capacity of the first lower diaphragm 11, a reinforcing rib 111 is welded betw...

Embodiment 2

[0055] see figure 1 and 5 Figure, a construction method of steel structure beam-column connection node, comprises the following steps:

[0056] S1, the installation of preset parts, the two steel columns 1 are located at the joints with the box girder 2, and the receiving parts are preset. The receiving parts are the second stressed connecting plate 14, and the second stressed connecting plate 14 is vertically arranged. And one side of the second stress connecting plate 14 is welded on the steel column 1 , and one second stress connecting plate 14 is respectively arranged on both sides of the steel column 1 along the width direction of the box girder 2 . Moreover, the width of the upper flange plate of the box girder 2 is equal to the distance between the two second force connecting plates 14, and the width of the optional lower flange plate of the box girder 2 is equal to the distance between the two second force connecting plates 14. The distance between the plates 14 , or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com