Two-way sucker rod

A sucker rod and one-way valve technology, applied in the direction of drill pipe, drilling equipment, wellbore/well parts, etc., can solve the problems of high energy consumption, low oil pumping rate, energy waste, etc., and achieve improved oil yield , Improve oil pumping efficiency and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

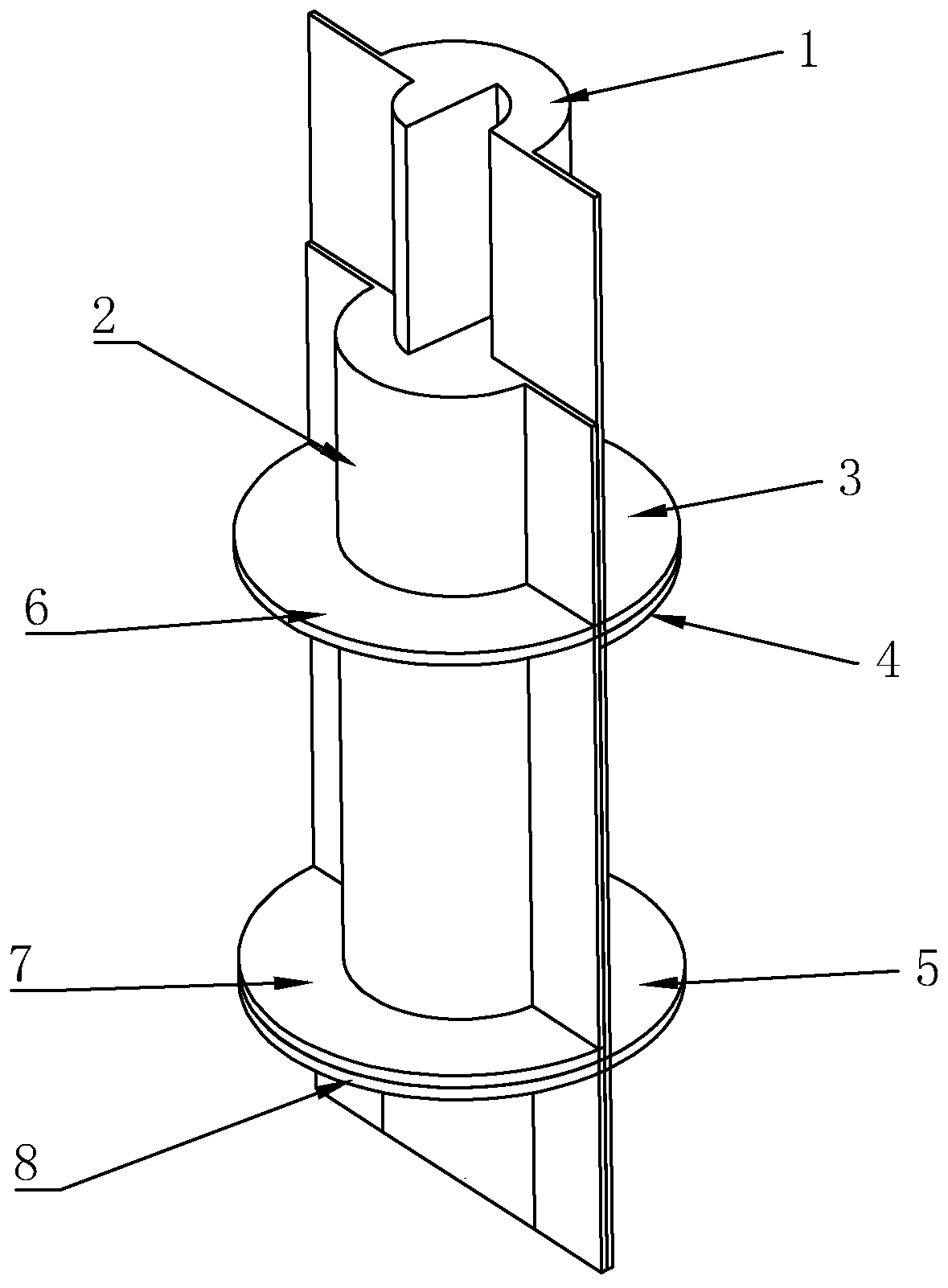

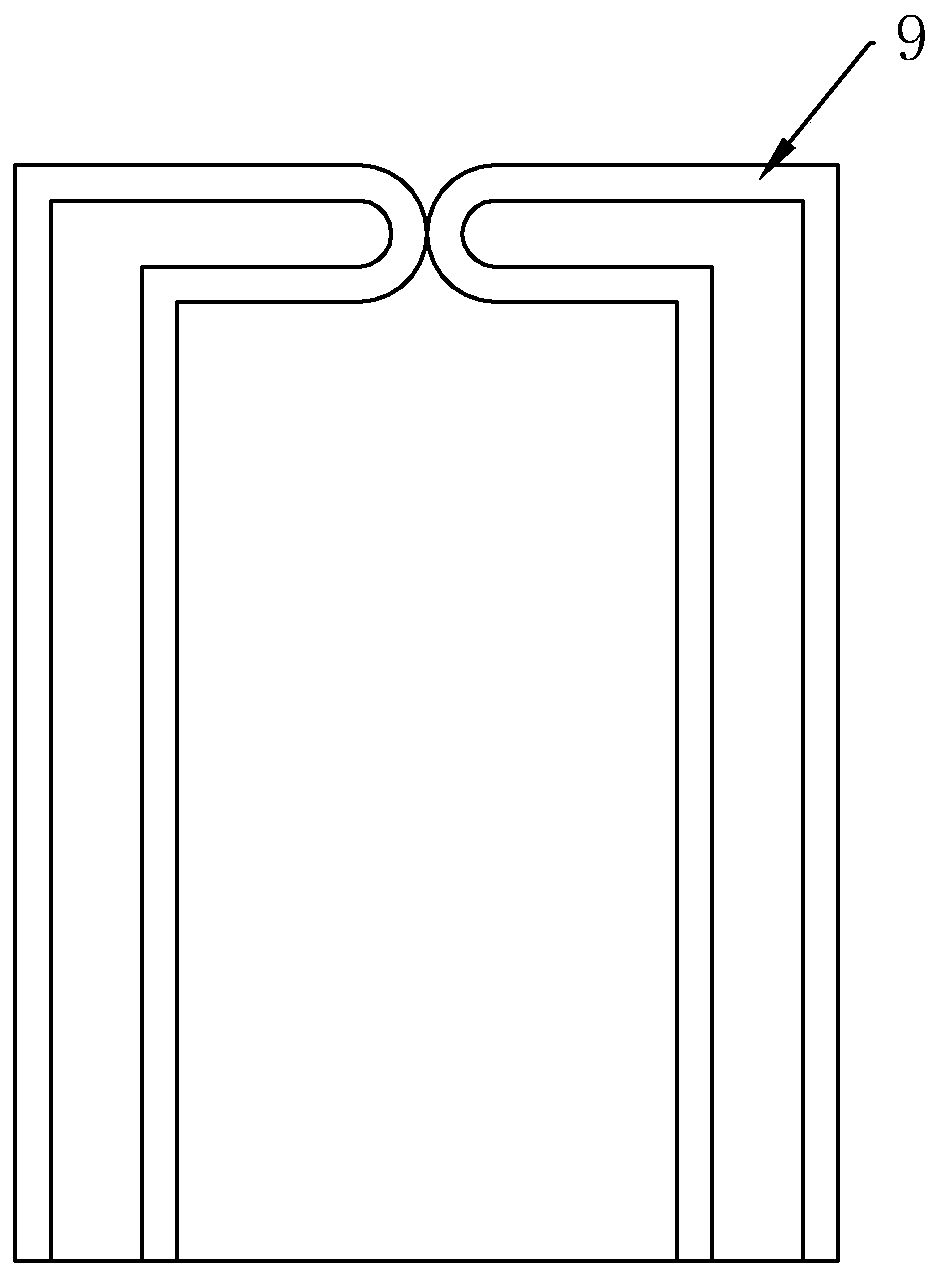

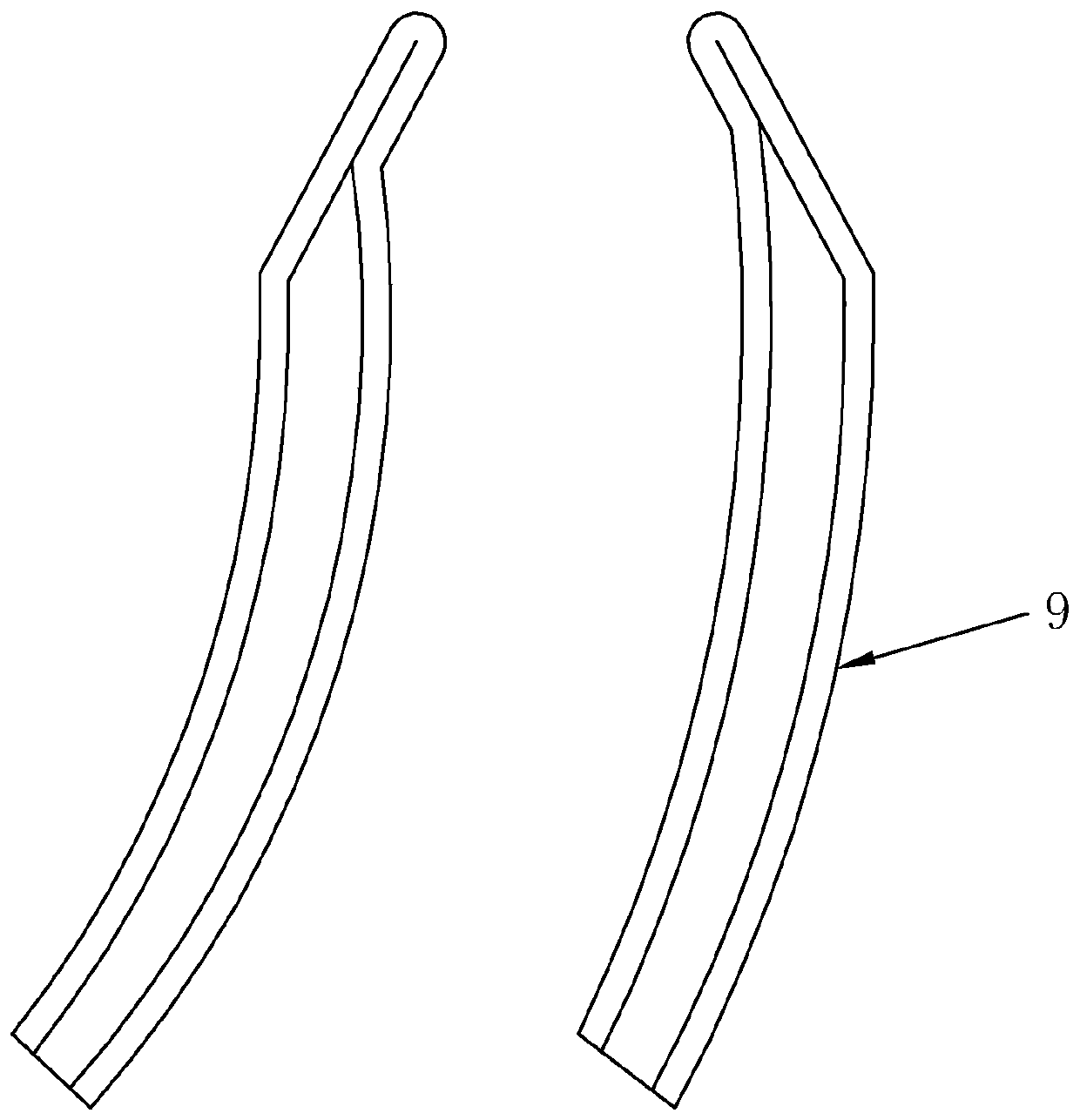

[0023] refer to Figure 1 to Figure 4 The embodiment of the two-way sucker rod of the present invention will be further described.

[0024] A two-way sucker rod, including an outer tube, an inner tube and a sucker rod, the inner tube is placed in the outer tube, the sucker rod is placed in the inner tube, and a vertical partition is connected to the inner tube to separate the inner tube It is the left cavity and the right cavity, the drawer includes the first drawer 1 and the second drawer 2 with the same structure, the partition is divided into a left partition and a right partition, and the left partition is fixed on the first drawer 1 , the right partition is fixed on the second drawer rod 2, moves up and down with the first drawer rod 1, the first drawer rod 1 and the second drawer rod 2 are spliced to form a cylinder, the first drawer rod 1 and the second drawer rod 2 are both It is composed of two semicircular cylinders spliced together, and the straight sides of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com