Supercharger and centrifugal vacuum oil purifier with supercharger

A supercharger and supercharger housing technology, applied in the direction of machines/engines, mechanical equipment, non-volume pumps, etc., can solve the problems of oil discharge pumps not working properly, excessive negative pressure of vacuum tanks, easy wear and tear, etc. , to avoid cavitation, reduce oil suction negative pressure, and reduce wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

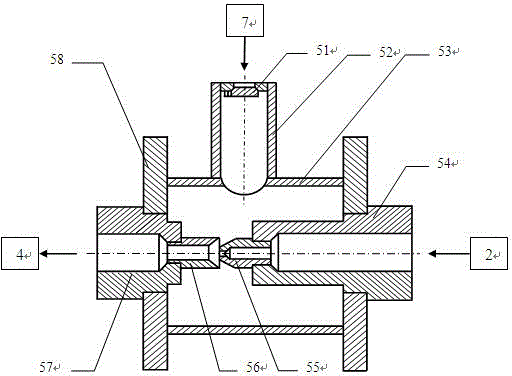

[0016] Supercharger designed by the present invention (see figure 1 ), characterized in that the supercharger 5 includes a check valve 51, a vacuum tank inlet pipe 52, a supercharger housing 53, a high-pressure oil pump connection pipe 54, a high-pressure oil injection pipe 55, a pressure mixing pipe 56, and an oil well pump connection pipe 57 and the flange 58, the two ends of the supercharger housing 53 are hermetically connected to form a closed body by the flange 58, and the high-pressure oil pump connecting pipe 54 is inserted into the supercharger housing 53 through the central seal of the flange 58 at one end , and the end or front end of the high-pressure oil pump connecting pipe 54 is provided with a high-pressure oil injection pipe 55; The end or front end is provided with a pressure mixing pipe 56, and the center lines of the supercharger ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com