Combustion light gas gun driven by convergent shock wave reflection induced detonation

A light gas cannon and detonation technology, applied in the field of ultra-high-speed launch, can solve the problems of reduced bottom pressure and unsatisfactory launch speed, and achieve the effects of stable performance, reduced experimental cost, and high operating efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0019] Based on the combustion light gas cannon driven by converging shock wave reflection inducing detonation of the present invention, its preferred embodiment is:

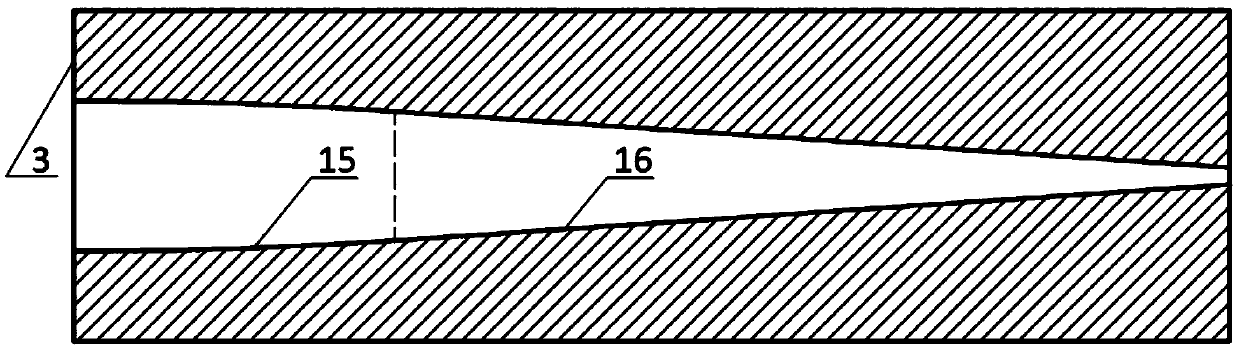

[0020] It includes a driving section, a driven section, a converging section, and a launch tube sequentially connected from back to front, and a target chamber is arranged at the front end of the launch tube;

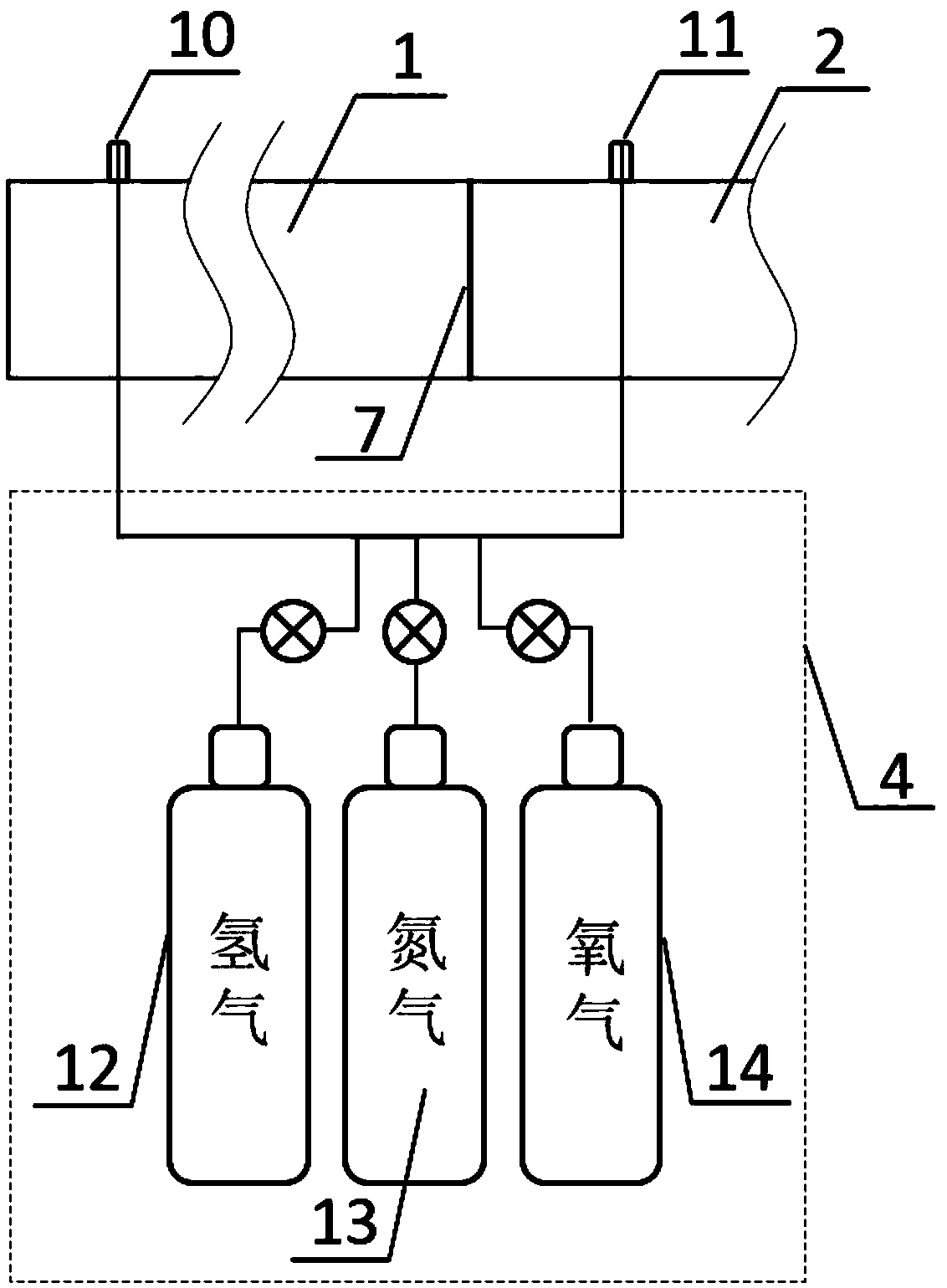

[0021] The driving section is a straight cylindrical structure with a constant circular inner section, its rear end is closed, and the pipe body is provided with a driving section gas injection hole, and the driving section gas injection hole is connected to the hydrogen and nitrogen high-pressure mixed gas injection pipe of the gas injection device ;

[0022] The driven section is a straight cylindrical structure with a constant circular inner section, a driven section diaphragm is provided at the connection between the driven section and the driving section, and the driven section tube body is provided ...

specific Embodiment

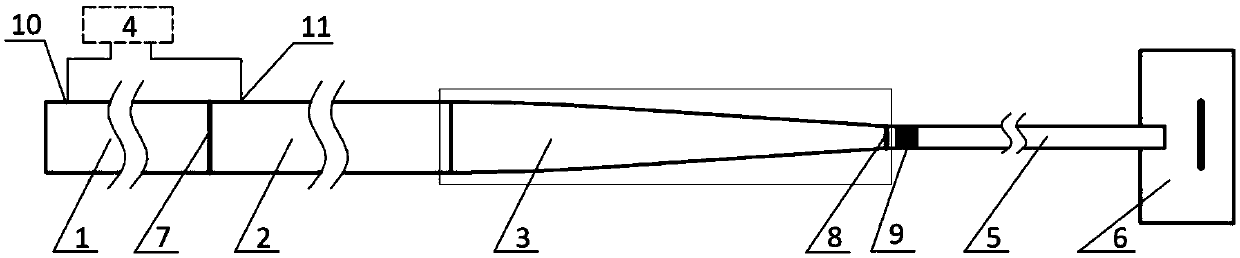

[0041] See attached figure 1 , a combustion light gas cannon driven by converging shock wave reflection induced detonation, which includes: a driving section 1, a driven section 2, a converging section 3, a gas injection device 4, a launch tube 5, and a target chamber 6, which are arranged in the driving section and The driven section diaphragm 7 at the joint of the driven section, the launching tube diaphragm 8 arranged at the joint of the converging section and the launching tube, the projectile 9 , the driving section gas injection hole 10 , and the driven section gas injection hole 11 .

[0042] The driving section 1 is a straight cylindrical structure with a constant circular inner section, one end is closed and the other end is open; the pipe body is provided with a driving section gas injection hole 10 to realize communication with the gas injection device 4, and the gas injection device 4 passes through the driving section gas injection hole 10 Fill the driving section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com