Light gas gun launcher for simulating explosive shock wave and high speed fragment coupling load

An explosion shock wave and coupling load technology, applied in the field of simulating light gas guns, can solve the problems of unpopularity, uncertainty of effectiveness, and high qualification requirements, and achieve easy operation and cost, accurate data of damage and response characteristic parameters, and experimental qualifications low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

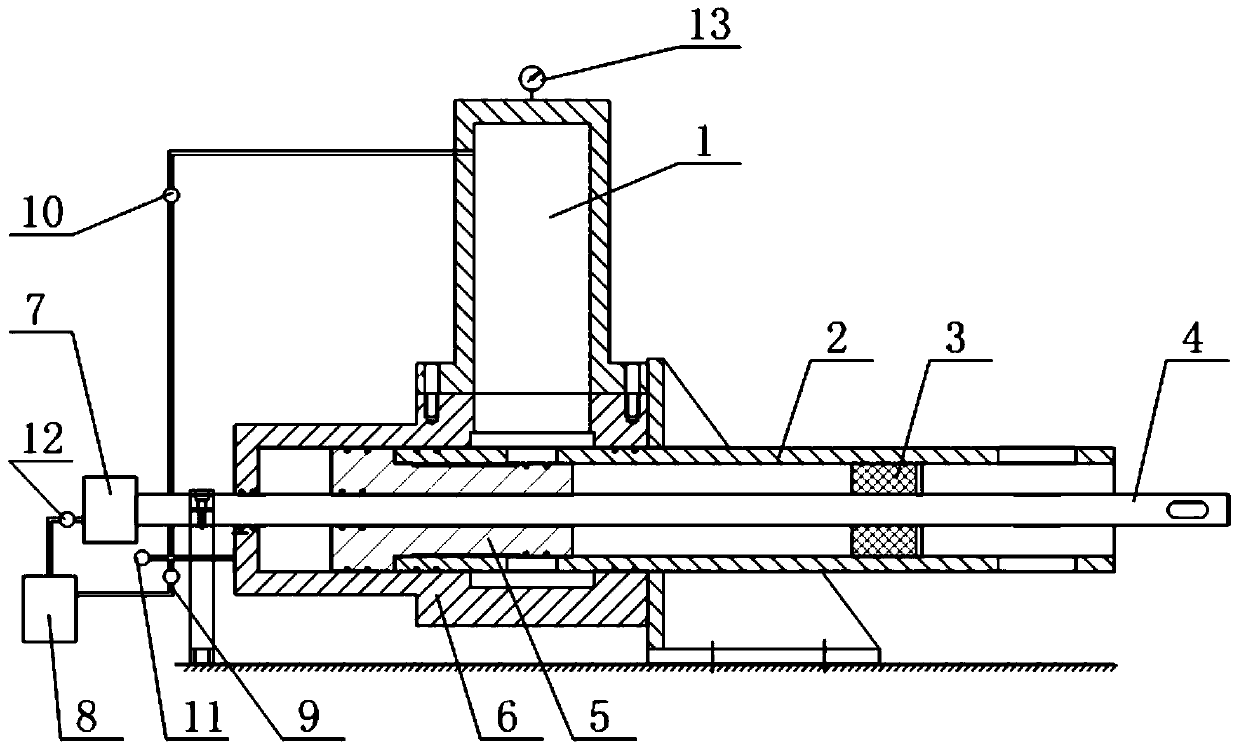

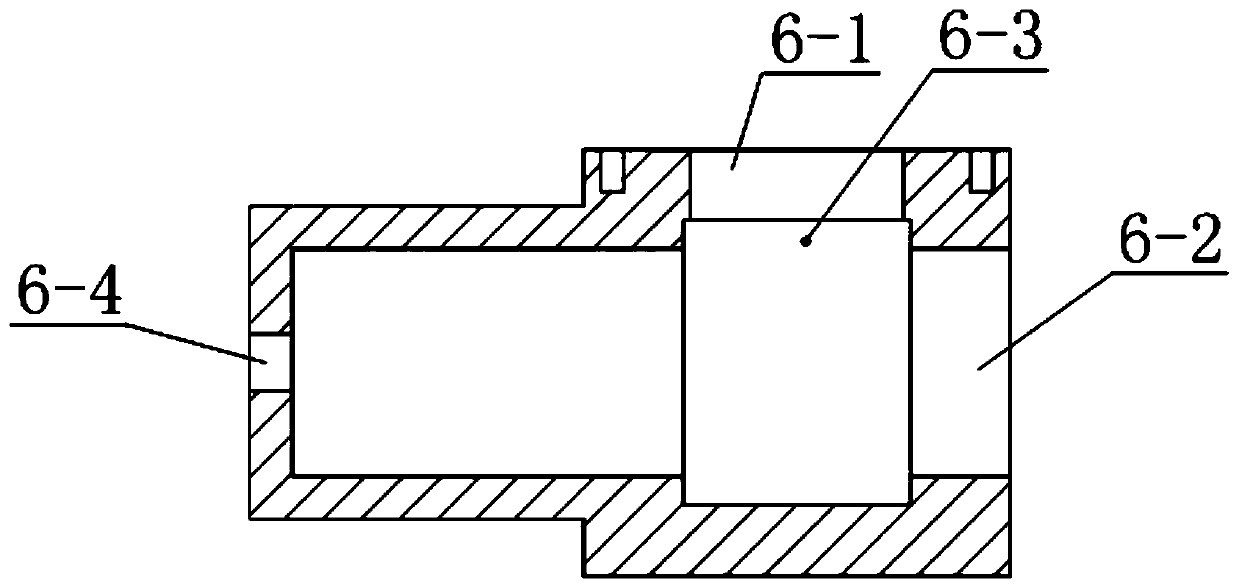

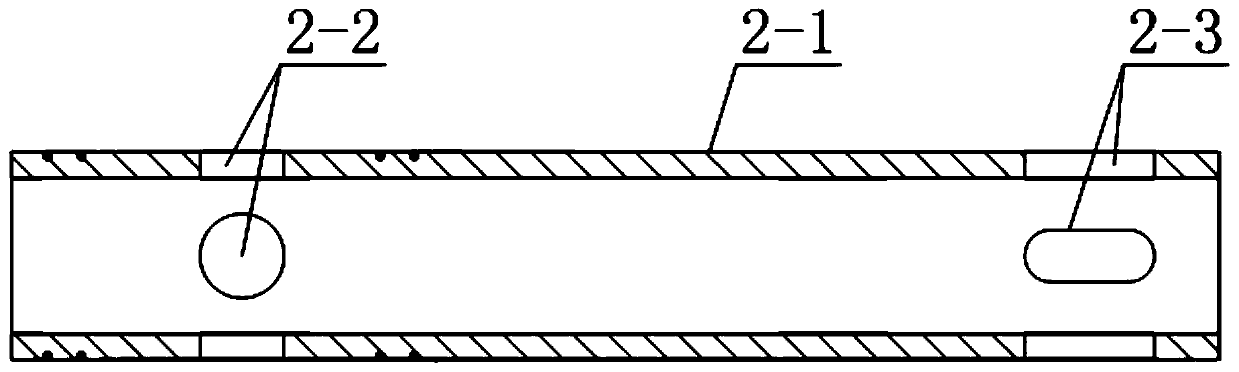

[0027] Specific implementation mode one, see figure 1 In the shown light gas cannon launching device, the high-pressure gas chamber 1 of the large-caliber light gas cannon is connected with the upper port 6-1 of the coupling connector 6 through a flange and a sealing O-ring; The left end face position of the light gas cannon launch tube 2 has an annular hole 6-3 through which the high-pressure gas chamber 1, the coupling connector 6 and the large-caliber light gas cannon launch tube 2 inner cavity are communicated with each other, Ensure that the gas pressure of the high-pressure chamber 1 before and after the test is the same as the gas pressure at the small end of the aluminum alloy piston 5; install a pressure gauge or a pressure sensor 13 on the high-pressure chamber 1 to monitor the pressure of the chamber; a large-caliber light gas gun The high-pressure gas chamber 1 is connected with the high-pressure gas storage tank 8 through the pipeline, the four-way and the solenoi...

specific Embodiment approach 2

[0035] Embodiment 2. The difference between this embodiment and Embodiment 1 is that the flying plate 3 is replaced by a foam (such as aluminum alloy foam) projectile, and the target structure to be studied is used for the underwater explosion equivalent loading simulator. By replacing it, the laboratory simulation test research on the structural damage characteristics of the explosion shock wave load in the air and the high-speed fragment coupling effect can be realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com