Three-level light-gas gun driven by compressed nitrogen

A technology for compressing nitrogen and light gas guns, applied in compressed air guns, weapons without explosives, weapon types, etc., can solve problems such as endangering the health of operators, increasing the difficulty of cleaning gun barrels, reducing experimental efficiency, and reducing experimental costs. , to avoid gun body ablation, the effect of simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

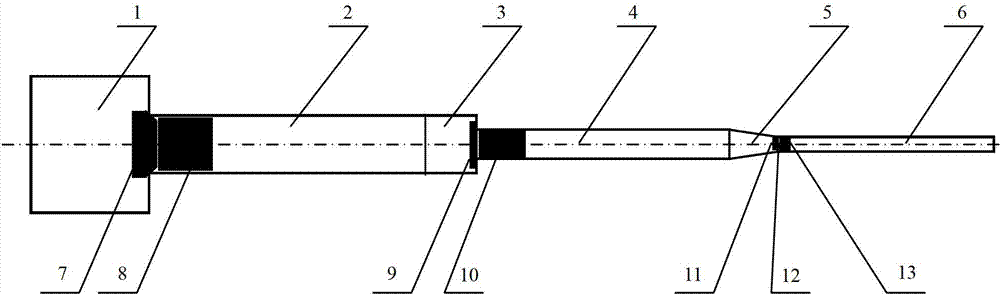

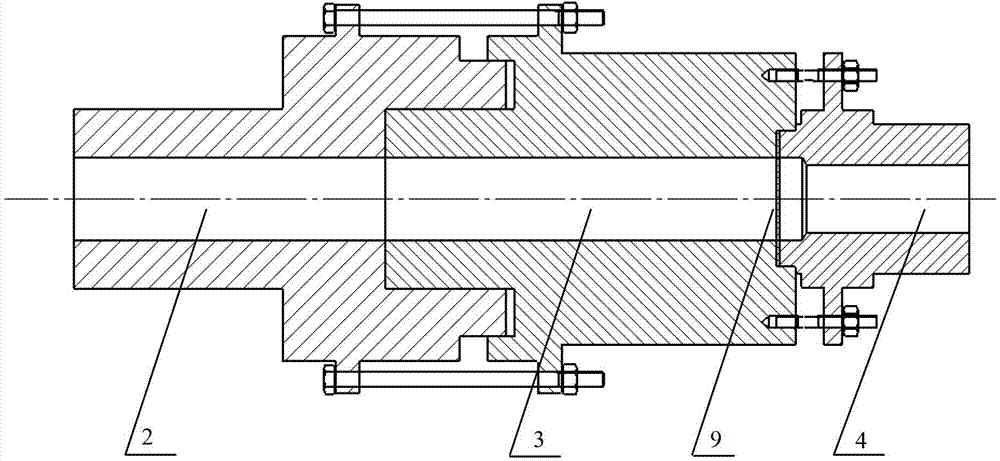

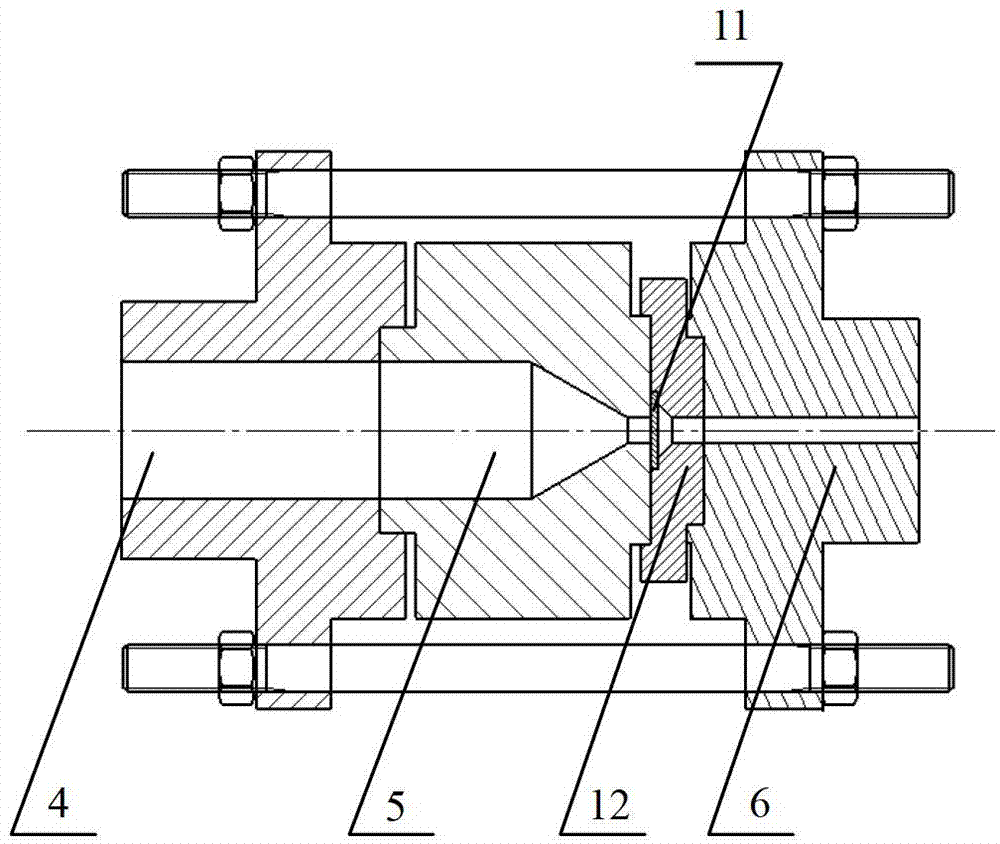

[0025] The basic process of the firing of the third-stage light gas gun: high-pressure nitrogen is stored in the first-stage gas chamber 1, and the high-pressure gas in the first-stage gas chamber 1 is released instantaneously through the quick opening valve 7 during launch, the high-pressure gas drives the first-stage piston 8 to move, and the first-stage piston 8 Compress the gas in the primary pump tube 2 to the secondary gas chamber 3 to a high-pressure state, the secondary diaphragm 9 ruptures under a certain pressure, the primary pump tube 2 gas drives the secondary piston 10 to move, and the secondary piston 10 compresses the secondary The gas in the pump tube 4 reaches the third-stage gas chamber 5 to a high-pressure state, the third-stage diaphragm 11 ruptures under a certain pressure, and the second-stage pump tube 4 gas drives the projectile 13 to accelerate in the launch tube 6, and the projectile 13 accelerates to the target speed.

[0026] The present invention invol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com