Ball mill impact collision simulation test bed and ball mill impact collision simulation method

A technology for simulating test benches and ball mills, applied in the direction of applying repeated force/pulsation force to test material strength, instruments, measuring devices, etc., which can solve the problems that the impact simulation test of steel balls, rocks and liners cannot be applied, and achieve reliable High-speed pulse impact, strong adaptability, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

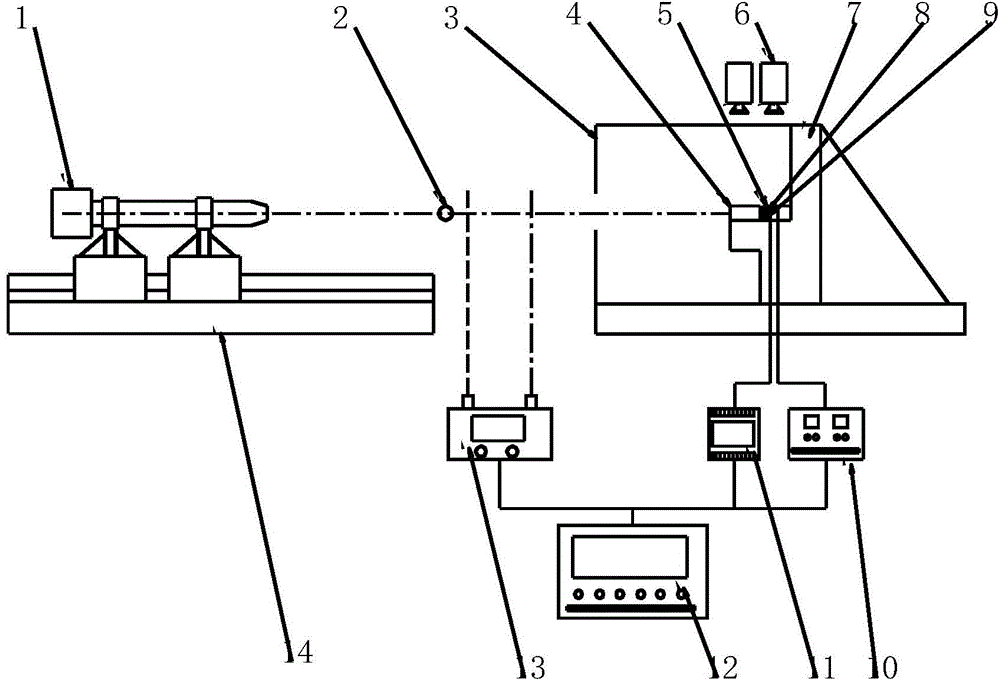

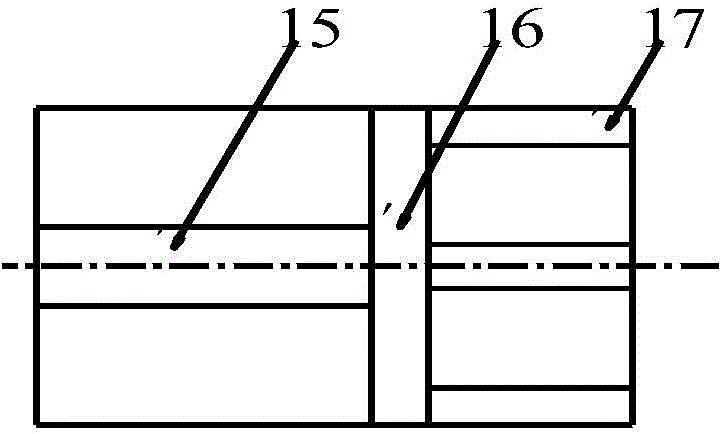

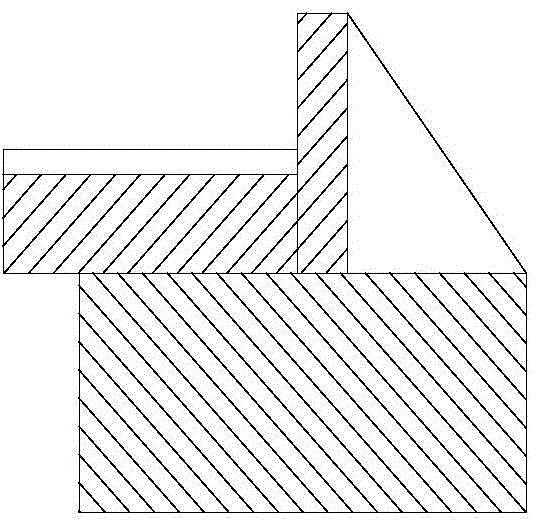

[0017] The ball mill impact collision simulation test bench of the present invention mainly consists of a light gas gun 1, a steel ball 2, a test chamber 3, a strain gauge 8, an impact acceleration sensor 9, a data acquisition system and a processing system, and the data acquisition system consists of a high-speed camera 6. It consists of a dynamic strain gauge 10 and a data acquisition card 11, and the processing system is composed of a computer processing system 12 and a photoelectric speed measuring device 13. The test box 3 is successively provided with a test box frame 7 for placing the cylindrical rock sample 4 and the cylindrical liner plate sample 5. The test box frame 7 includes a slide block 15 with an arc groove in the middle, and a slide block 15 arranged on the slide block. The baffle plate 16 of the slider 15 on the 15 side is symmetrically pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com