Small two-stage light-gas gun

A light air gun, small technology, applied in the types of weapons, compressed air guns, weapons without explosives, etc., can solve the problems of inability to increase the projectile launching speed, occupy a large space, and cannot be sealed, so as to improve safety and environmental protection, The effect of small footprint and reduced test cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

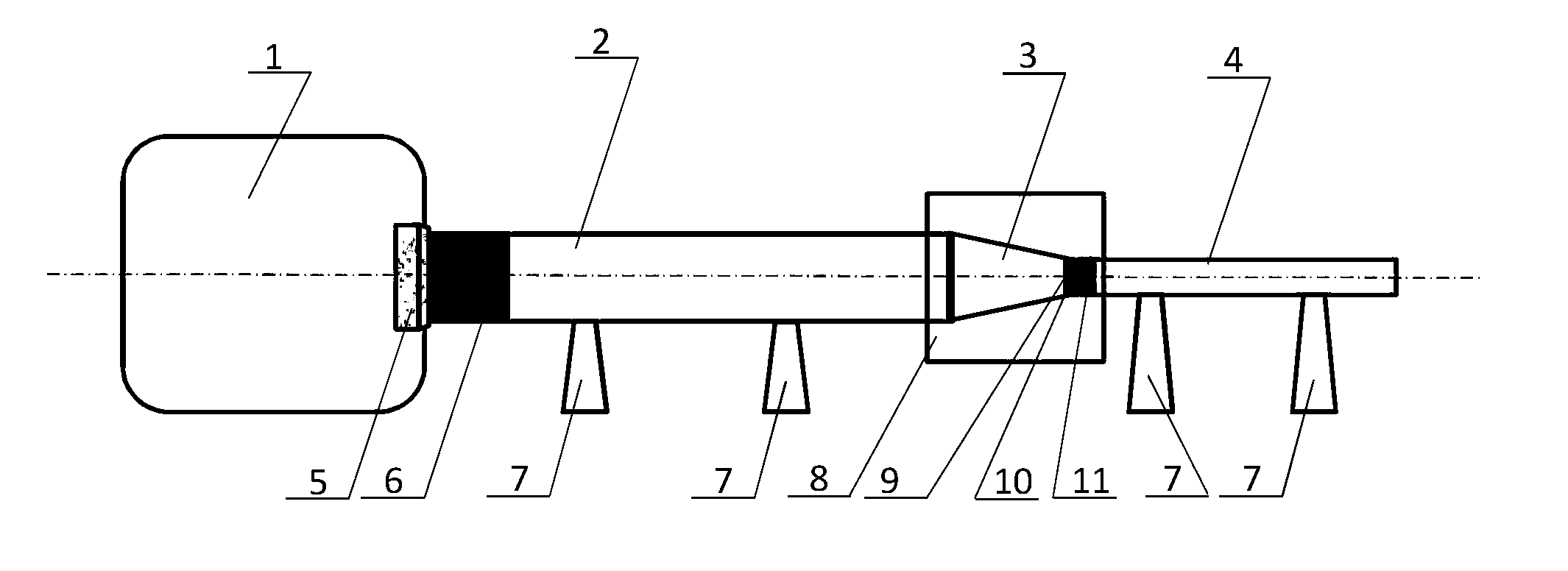

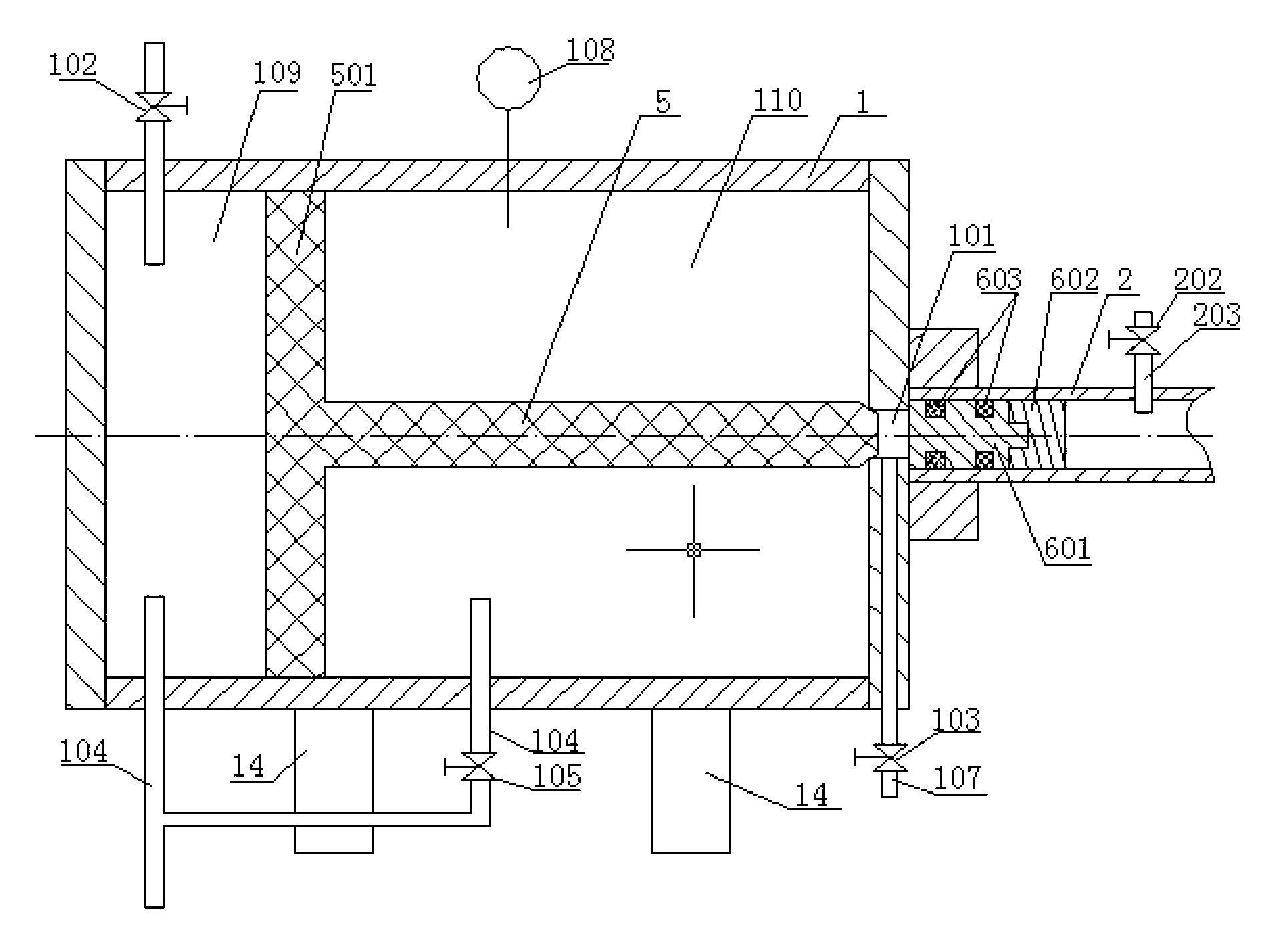

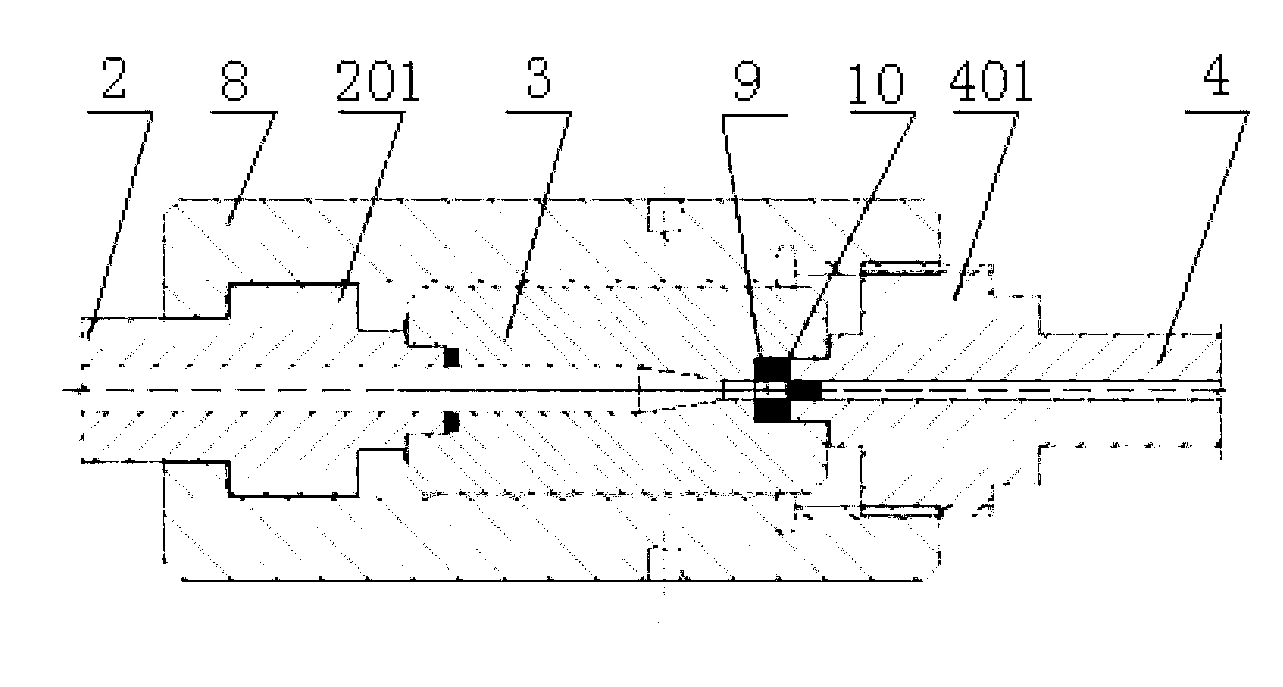

[0014] Specific implementation mode one: combine Figure 1-Figure 6 Describe this embodiment, a small two-stage light gas gun in this embodiment includes a cylinder 1, a pressure guide tube 2, a stamping column 3, a launch tube 4, a piston handle 5, a pressure guide body 6, a diaphragm 9, a ruptured membrane Device 10, first sealing ring 12, metal sealing ring 13, support 14 and a plurality of support seats 7; the cylinder 1 is a cylinder with both ends closed, and the middle part of one end of the cylinder 1 is provided with an air guide hole 101 , the cylinder 1 is equipped with a piston handle 5, the piston 501 on the piston handle 5 is in sliding contact with the inner peripheral surface of the air chamber 1, the end of the piston handle 5 points to the air guide hole 101 and the two are coaxially arranged, the piston 501 connects the cylinder The cylinder 1 is divided into a balance chamber 109 and an air chamber 110;

[0015] A first cylindrical hole 301 is provided in ...

specific Embodiment approach 2

[0022] Specific implementation mode two: combination Figure 1-Figure 6 Describe this embodiment, the outer wall of the metal cylinder 601 of this embodiment and the inner wall of the pressure guiding tube 2 are sealed by the rubber sealing ring set on the metal cylinder 601; The membrane breaker 10 is sealed, the membrane breaker 10 is sealed and connected to the launch tube 4 through the rubber sealing ring installed on the membrane breaker 10, and the pressure guiding tube 2 is sealed and connected to the punching column 3 through the rubber sealing ring installed on the punching column 3 . Such setting ensures a good seal during the process of compressing hydrogen, effectively ensuring the high-speed launch of projectiles under high pressure or ultra-high pressure. This embodiment solves the problem of effective conversion of high-pressure gas driving energy. Or helium, controlled by multiple factors such as piston, stamping column and diaphragm. Due to the limitation of...

specific Embodiment approach 3

[0023] Specific implementation mode three: combination Figure 4 The present embodiment will be described. The cross sections of the first seal ring 12 and the metal seal ring 13 in this embodiment are both circular. Such an arrangement effectively ensures that the pressure guide body compresses the hydrogen until the membrane ruptures without hydrogen leakage. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com