Rotary type high-speed bump test device for circular test piece

A technology of impact test and test piece, applied in the field of space debris protection test, can solve the problems of inability to complete multi-angle high-speed impact test, difficulty in clamping and fixing, etc., and achieve the effect of convenient clamping and fixing of test piece and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

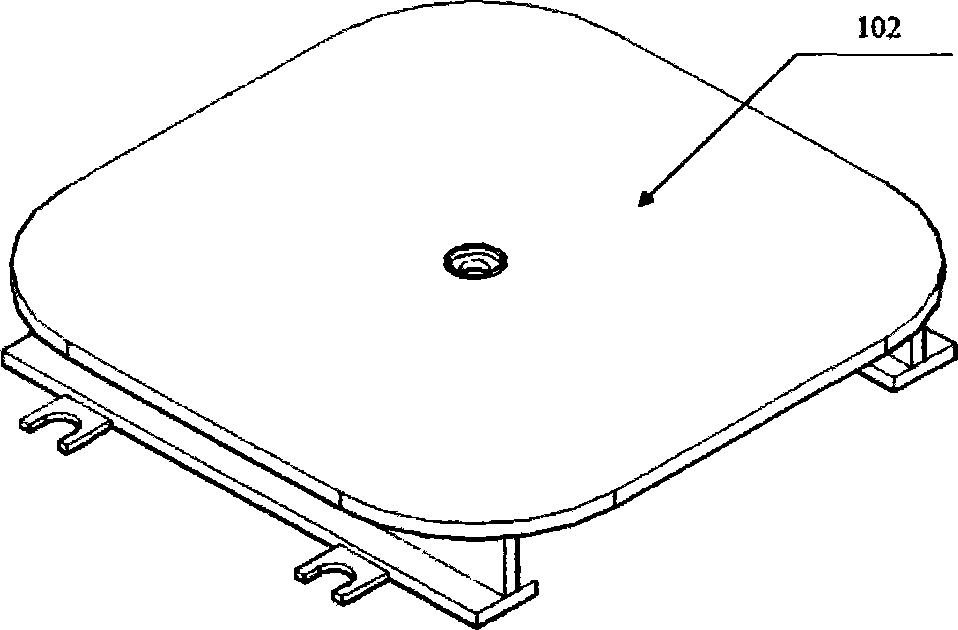

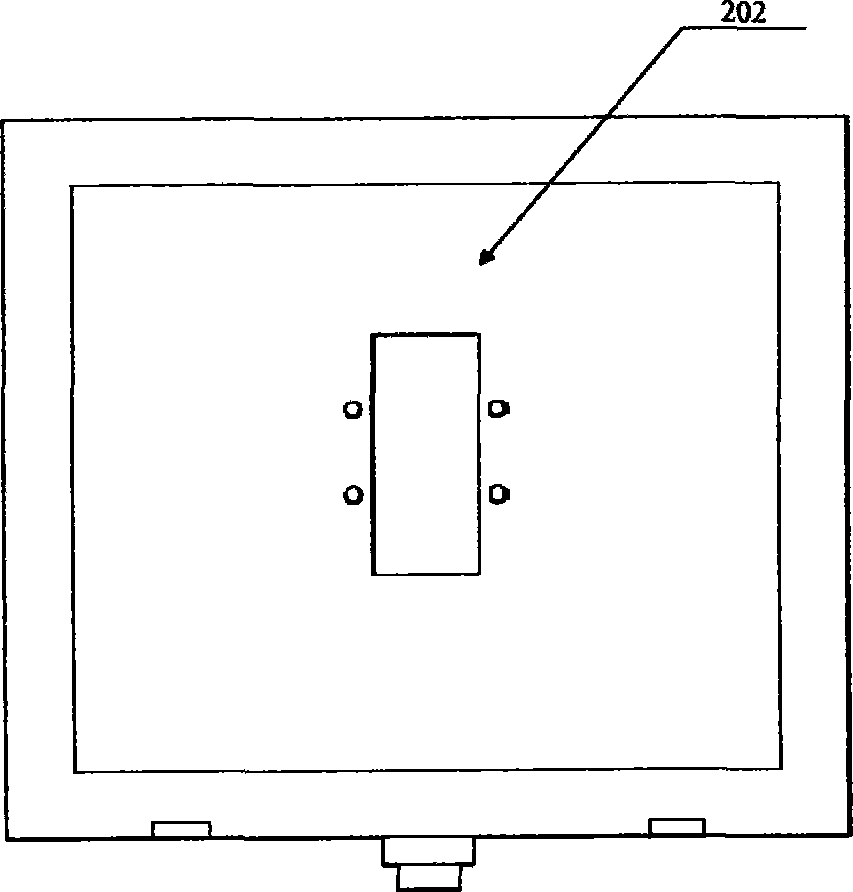

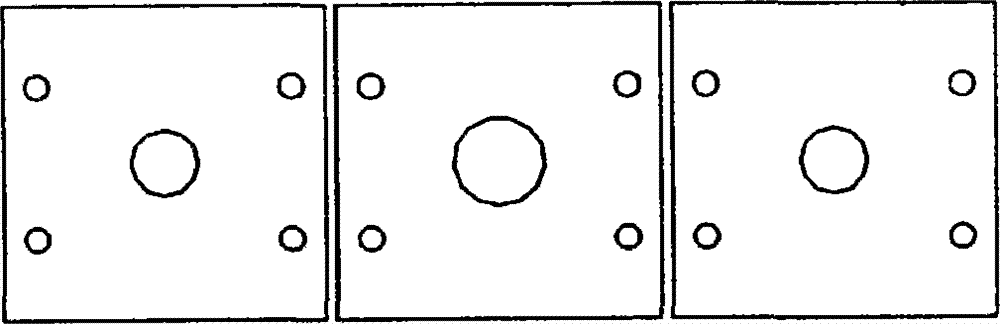

[0023] like figure 1 , figure 2 and Figure 4 As shown, a rotatable high-speed impact test device for a circular test piece includes a rotating base 102, a rotating panel 202, and a circular test piece fixing device 203. The rotating base 102 and the rotating panel 202 are connected through a flange. The multi-angle rotation of the rotating panel can be realized, and the circular test piece fixing device 203 is fixedly connected with the rotating panel 202 to ensure that the impact point is at the center of the plate, and the device is fixed in the target compartment of the secondary light gas gun, and the test piece The circular test piece fixture 203 is used for clamping and fixing. The circular test piece fixture 203 is composed of three flat plates with circular holes of different diameters in the center. The diameter of the hole in the middle plate is larger than the diameter of the plates on both sides. The parts are embedded in the middle plate, and the plates on bo...

Embodiment 2

[0029] like Figure 5 , Image 6 , Figure 7 , Figure 8 As shown, the rotation angles of the rotating panel are 0 degrees, 15 degrees, 30 degrees, and 45 degrees respectively. After adjusting the angle of the test, the rotating panel and the rotating base are effectively fixed by bolts 401. The change of the impact angle of the circular test piece clamped and fixed by the test piece fixture. The device can provide experimental basis for space debris risk assessment and structural optimization design of structural materials in the aerospace field.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com