Experimental system of coupling loading of non-drug underwater explosion shock wave and high-speed fragmentation

A technology of underwater explosion and experimental system, which is applied in the direction of impact test, machine/structural component test, measuring device, etc. It can solve the problems of inaccurate results, lack of experimental verification, uncertainty of validity, etc., and achieve high repeatability , complete data and low risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

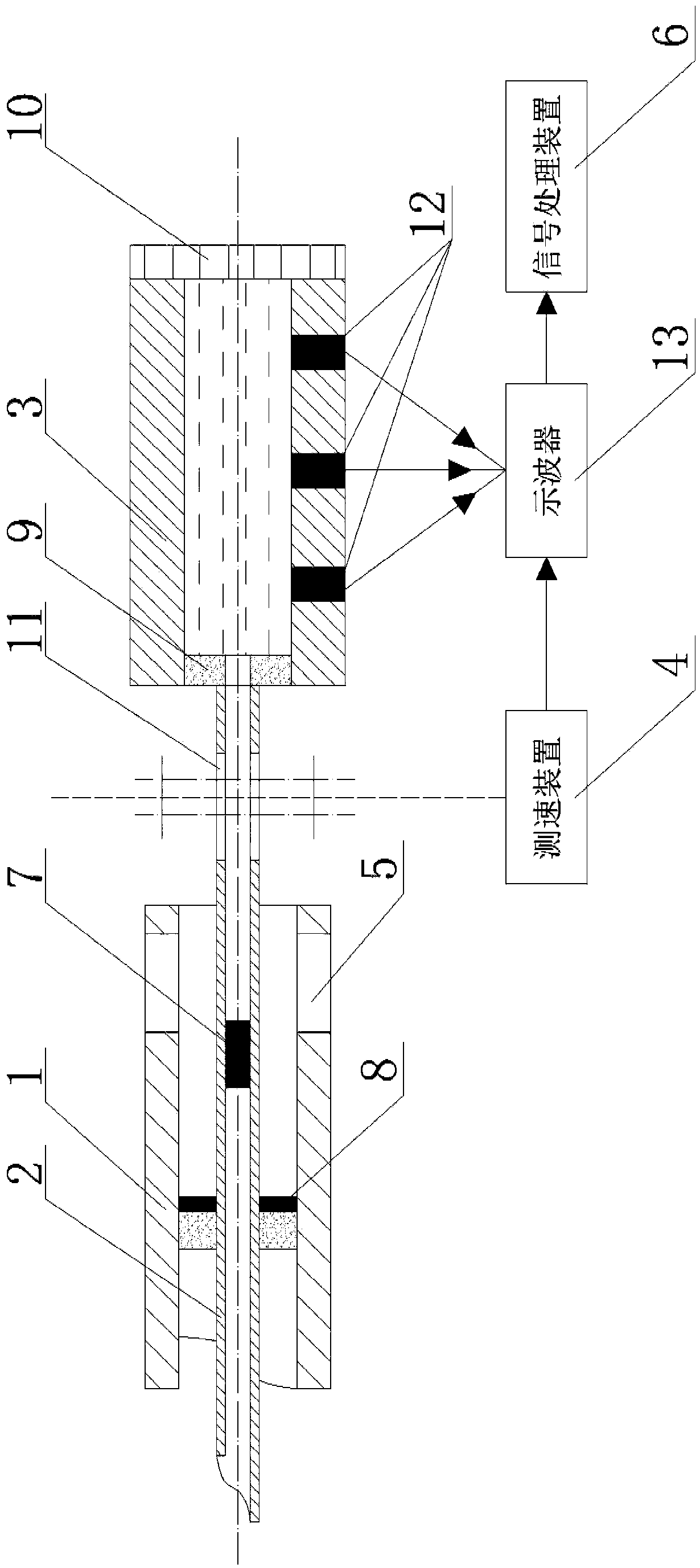

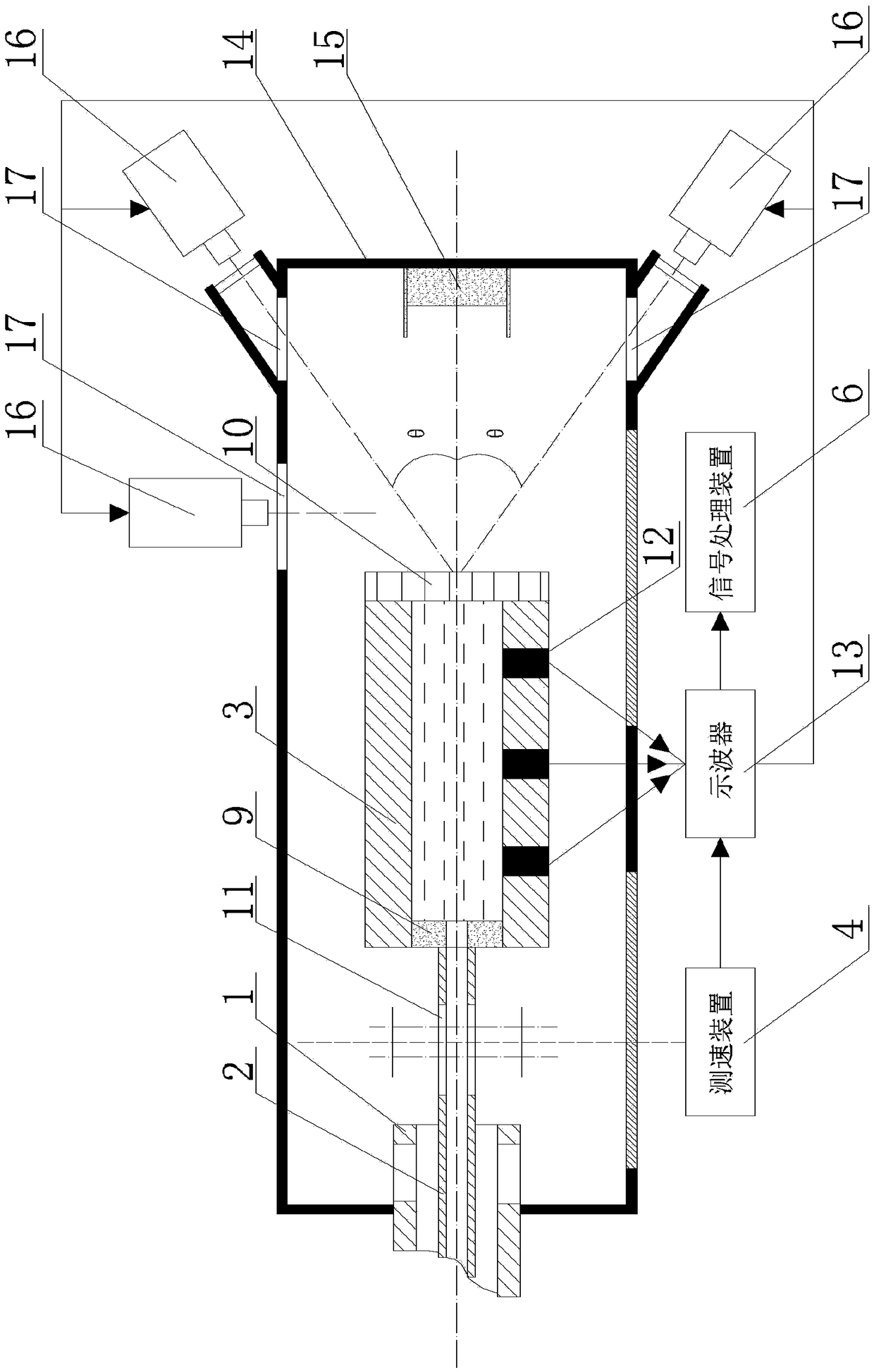

[0023] The non-drug type underwater explosion shock wave and high-speed fragment coupling loading experiment system of the present invention, such as figure 1 and figure 2 As shown, it includes a large-caliber light gas cannon launch tube 1, a small-caliber light gas cannon launch tube 2, an equivalent loading simulator 3, a velocity measuring device 4, a shock wave measuring device and a signal processing device 6;

[0024] like figure 1 As shown, the small-caliber light gas cannon launch tube 2 is coaxially sleeved in the large-caliber light gas cannon launch tube 1; The high-pressure air chamber of the light gas gun is connected;

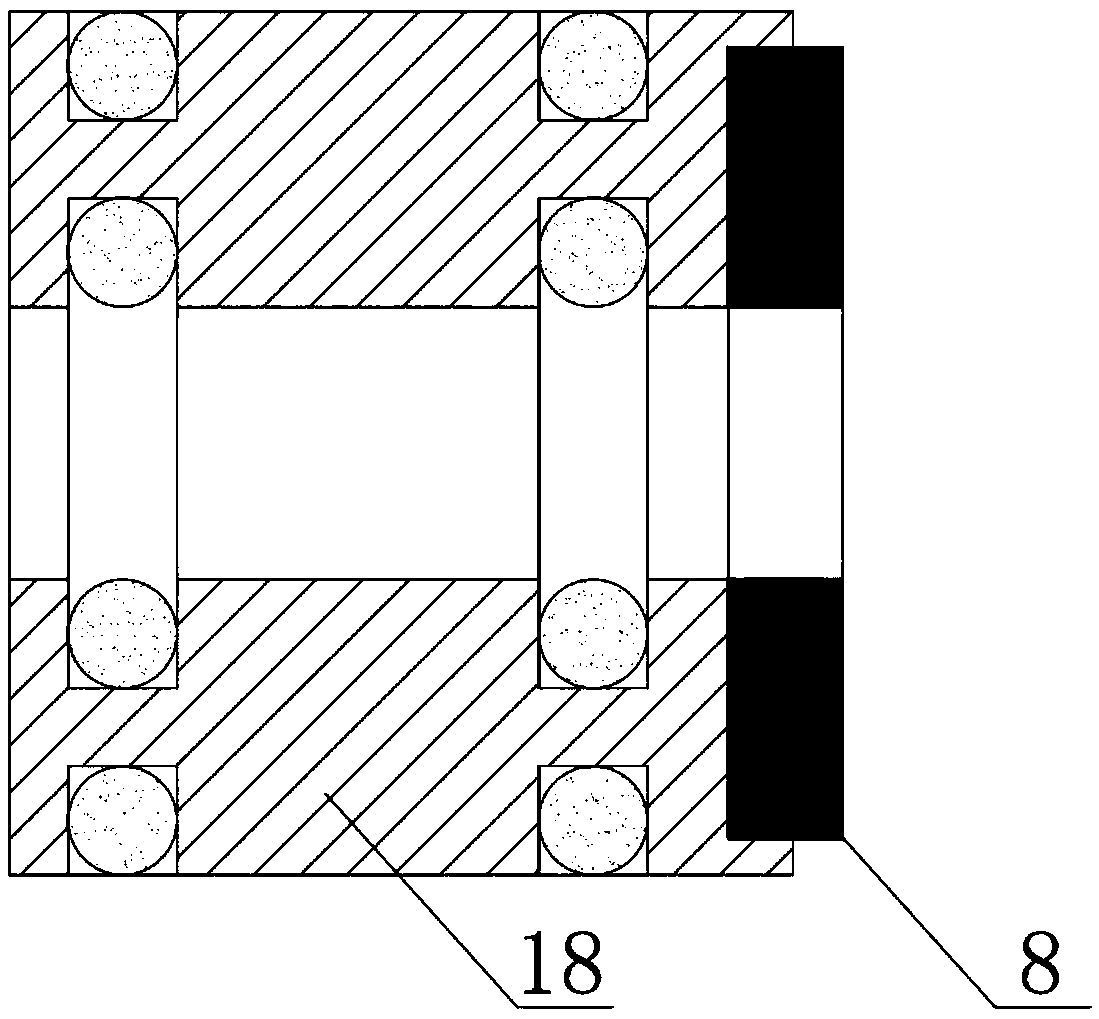

[0025] High-speed fragments 7 are filled in the small-caliber light gas cannon launch tube 2, and an annular high-speed flying plate 8 is filled between the inwall of the large-caliber light gas cannon launch tube 1 and the outer wall of the small-caliber light gas cannon launch tube 2. When the large-caliber light gas cannon launch tube 1 is...

specific Embodiment approach 2

[0036] The difference between the second embodiment and the first embodiment is that, as figure 1 and figure 2 As shown, there is an interval between the other end of the large-caliber light gas cannon launch tube 1 and the equivalent loading simulator 3; Port 11, and the small-caliber light gas cannon launch tube vent 11 is located at the interval between the large-caliber light gas cannon launch tube 1 and the equivalent loading simulator 3;

[0037] Velocimeter 4 comprises two-way laser velocity-measuring device, and the laser light path of these two-way laser velocity-measuring device can pass through small-caliber light gas cannon launch tube vent 11, and optical path and the main shaft of small-caliber light gas cannon launch tube 2 are perpendicular to each other.

[0038] When the high-speed fragment 7 passes through the vent 11 of the small-caliber light gas cannon launch tube, the velocity of the high-speed fragment 7 is measured by two-way laser velocity measuring...

specific Embodiment approach 3

[0039] The difference between the third embodiment and the first or second embodiment is that, as figure 1 and figure 2The shown shock wave measuring device includes a plurality of pressure sensors 12 , which are arranged on the side wall of the equivalent loading simulator 3 and arranged at intervals along the axis of the equivalent loading simulator 3 .

[0040] A plurality of pressure sensors 12 are respectively used to measure the pressure of the shock wave in water at different positions of the equivalent loading simulator 3, and the pressure parameters are sent to the signal processing device 6, and the attenuation characteristics and velocity characteristics of the shock wave pressure in the water are calculated by the signal processing device 6 and the shock wave pressure acting on the structural target 10 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com