Flow-throttling hole hydraulic buffer

A technology of hydraulic buffers and orifices, applied in the field of hydraulic buffers, can solve the problems of small operating temperature range, impact on buffering performance, and inability to fully exert the buffering effect, and achieve the effect of wide operating temperature range and stable buffering performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

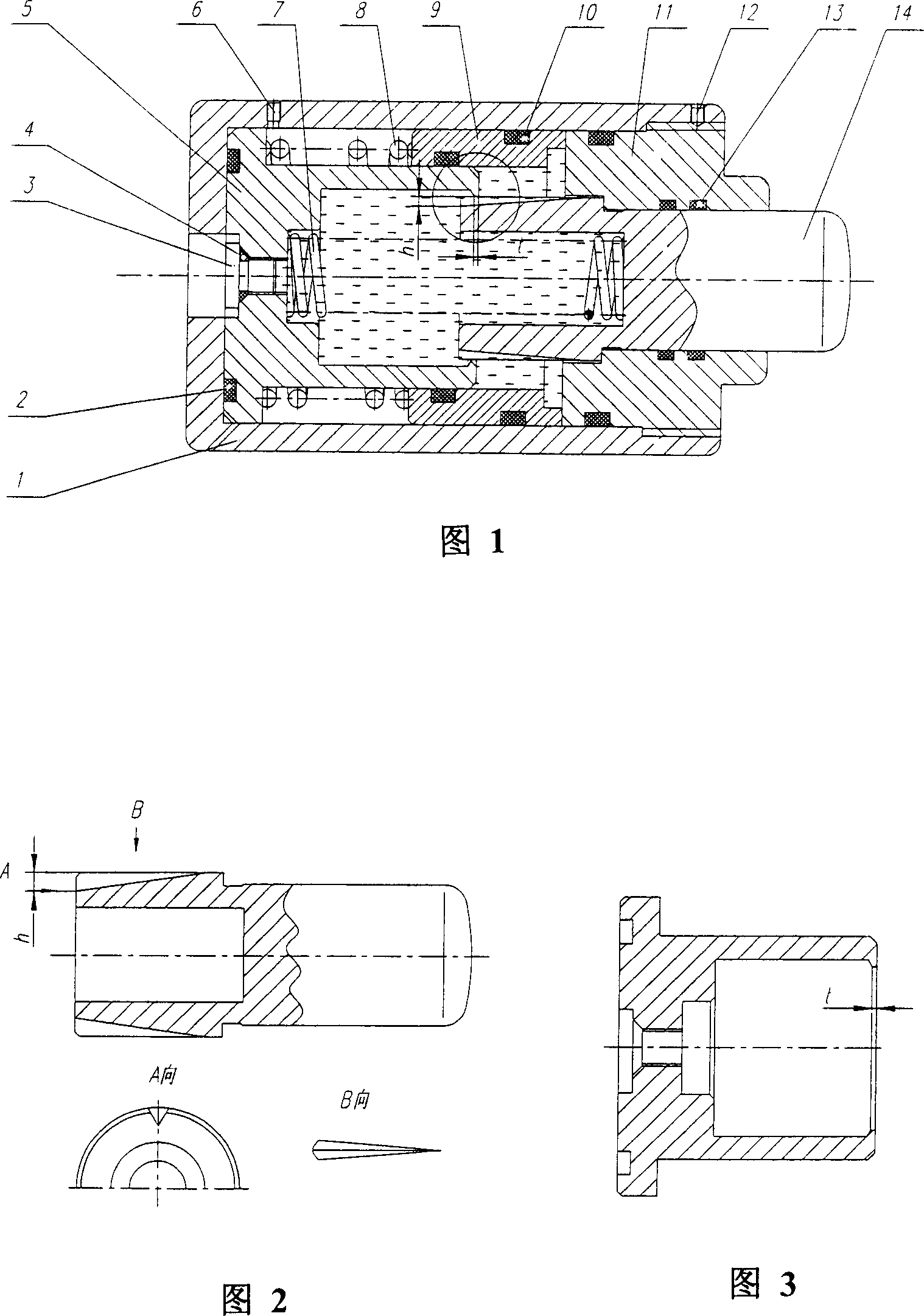

[0012] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

[0013] As shown in Figure 1, serial number 1 is a cylindrical shell, which is equipped with buffer parts, hydraulic oil and seals inside, and equipped with equipment installation interfaces on the outside. Serial numbers 2, 4, 10, and 13 are O-rings to prevent hydraulic oil from leaking. No. 3 is the filling screw plug, which can add or discharge hydraulic oil from the screw hole after unscrewing it. The throttling wall 5 has a cylindrical shape and an inner cavity, the left end of which matches the inner circle of the housing 1, and the outer circle of the right end matches the inner circle of the pressurized sliding sleeve 9, and the thickness of the right end of the inner circle is t (see Figure 3). The throttling wall is thick, and the inner circle of the right end of the throttling wall 5 cooperates with the outer circle of the left end of the buff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com