Control method and control circuit of rotary anode X-ray tube

A technology of X-ray tube and control method, which is applied in the control field of Xuanyang X-ray tube, can solve the problems of rising, consuming electric energy, and reducing the X-ray output rate of Xuanyang X-ray tube, so as to improve the tube X-ray Line emission efficiency, improve emission efficiency, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

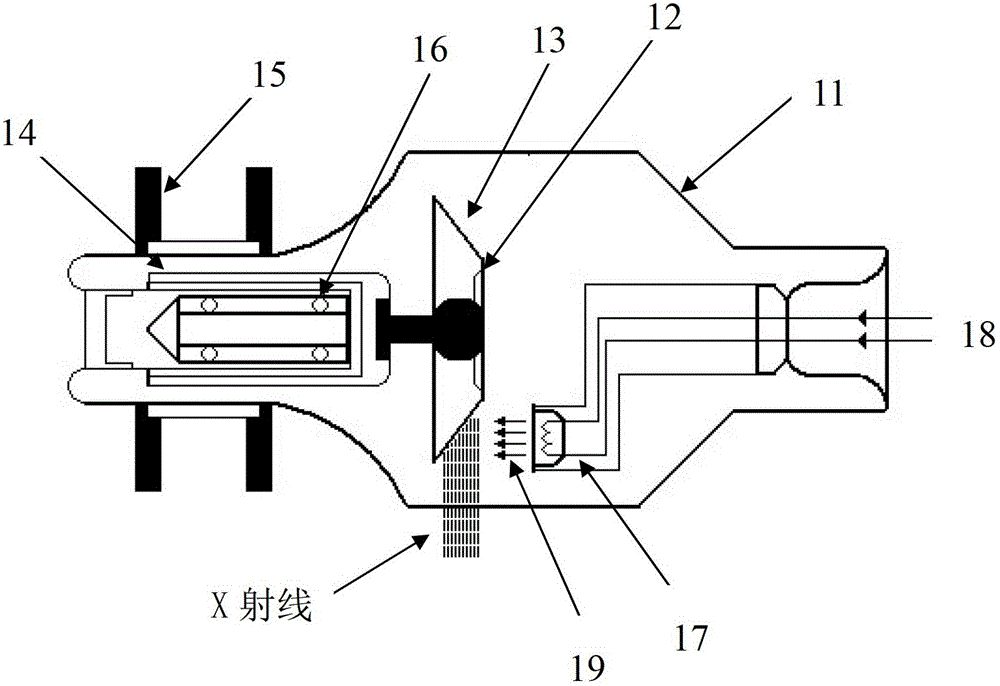

[0038] refer to figure 2 and Figure 5A sun-rotating X-ray tube provided in the first embodiment includes a vacuum tube 11 made of glass and an AC motor connected to the vacuum tube 11; the AC motor includes an electromagnetic stator 15, a rotor 14 and a bearing 16; An anode target 12 and a cathode 17 are arranged oppositely. The anode target 12 is made of tungsten metal and is in the shape of a trapezoidal disc. The cathode 17 is a filament. The slope 13 (also known as the waist surface) of the anode target 12 is the target surface; the anode The center of the target 12 is fixed on the rotor 14 of the AC motor, wherein, the connection relationship between the AC motor and the vacuum tube 11 (this connection relationship can realize that the rotor 14 of the AC motor is connected with the anode target 12 in the vacuum tube 11 while not affecting the connection of the vacuum tube 11 Vacuum state) belongs to the prior art, and will not be cumbersome here; the cathode 17 is faci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com