Atmosphere corrosion resisting steel plate having high strength and excellent bending formability and method for production thereof

A technology for bending workability and high-strength steel plates, applied in the direction of manufacturing tools, furnace types, furnaces, etc., can solve problems such as cracks and failure to meet specifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

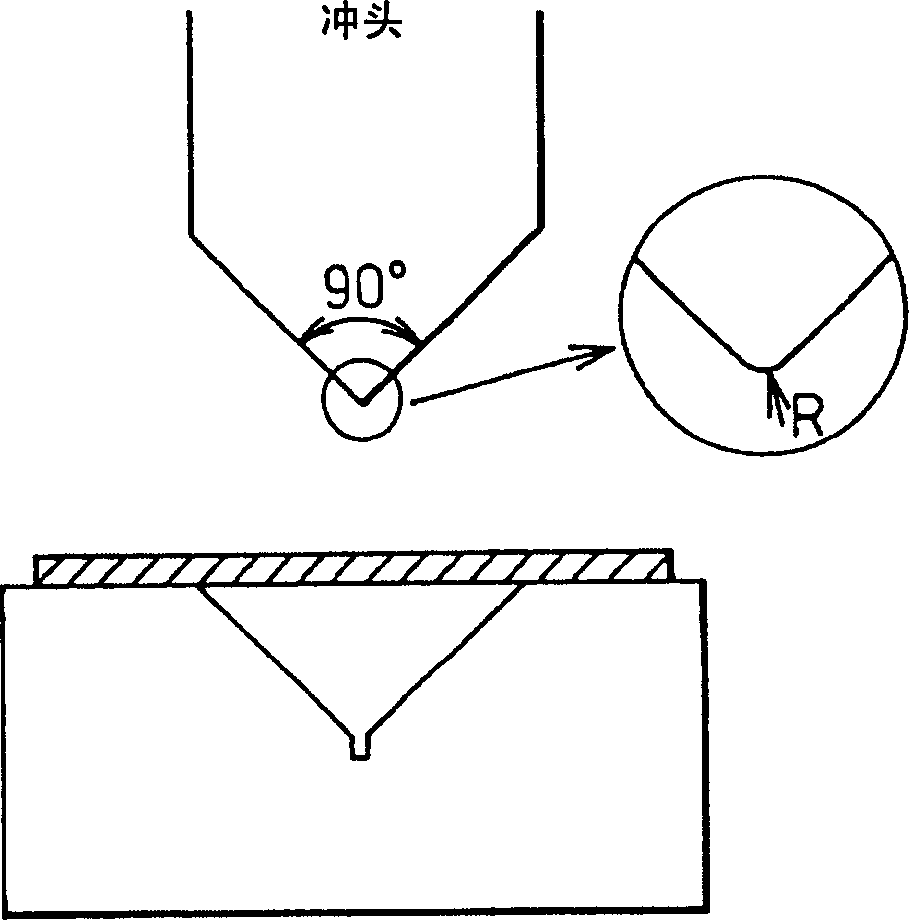

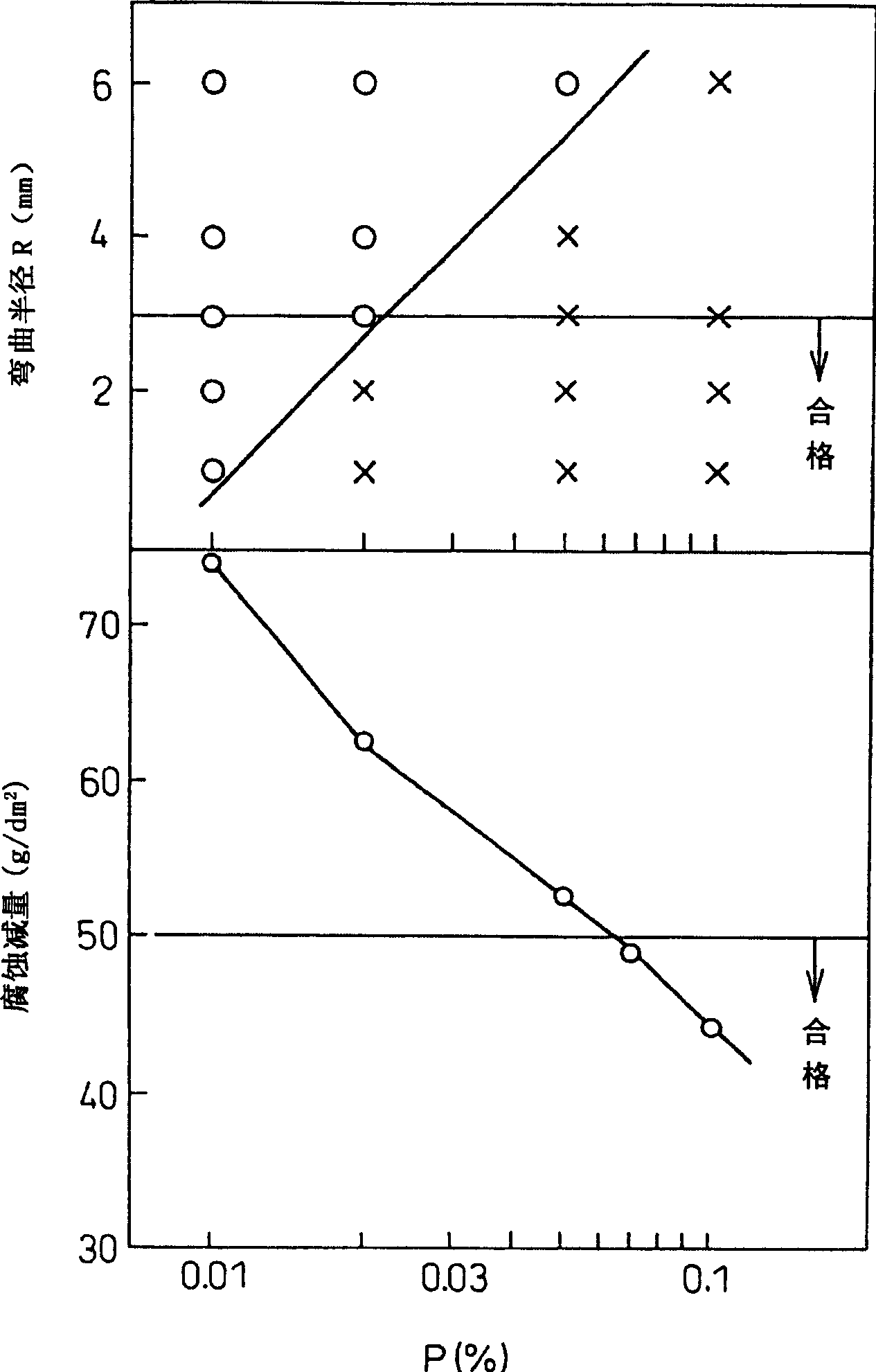

[0045] After tapping steel numbers 1 to 12 with various components shown in Table 1, steel materials were produced under the rolling conditions shown in Table 2, samples were cut out, and the characteristics were evaluated after the surface was shot-peened. The evaluation is to measure yield strength, tensile strength, and total elongation by tensile test. Then, bending was performed using a punch with a bending angle of 90° C. and a bending radius (R) of 3 mm at the end, and the presence or absence of cracks in the bent portion was investigated.

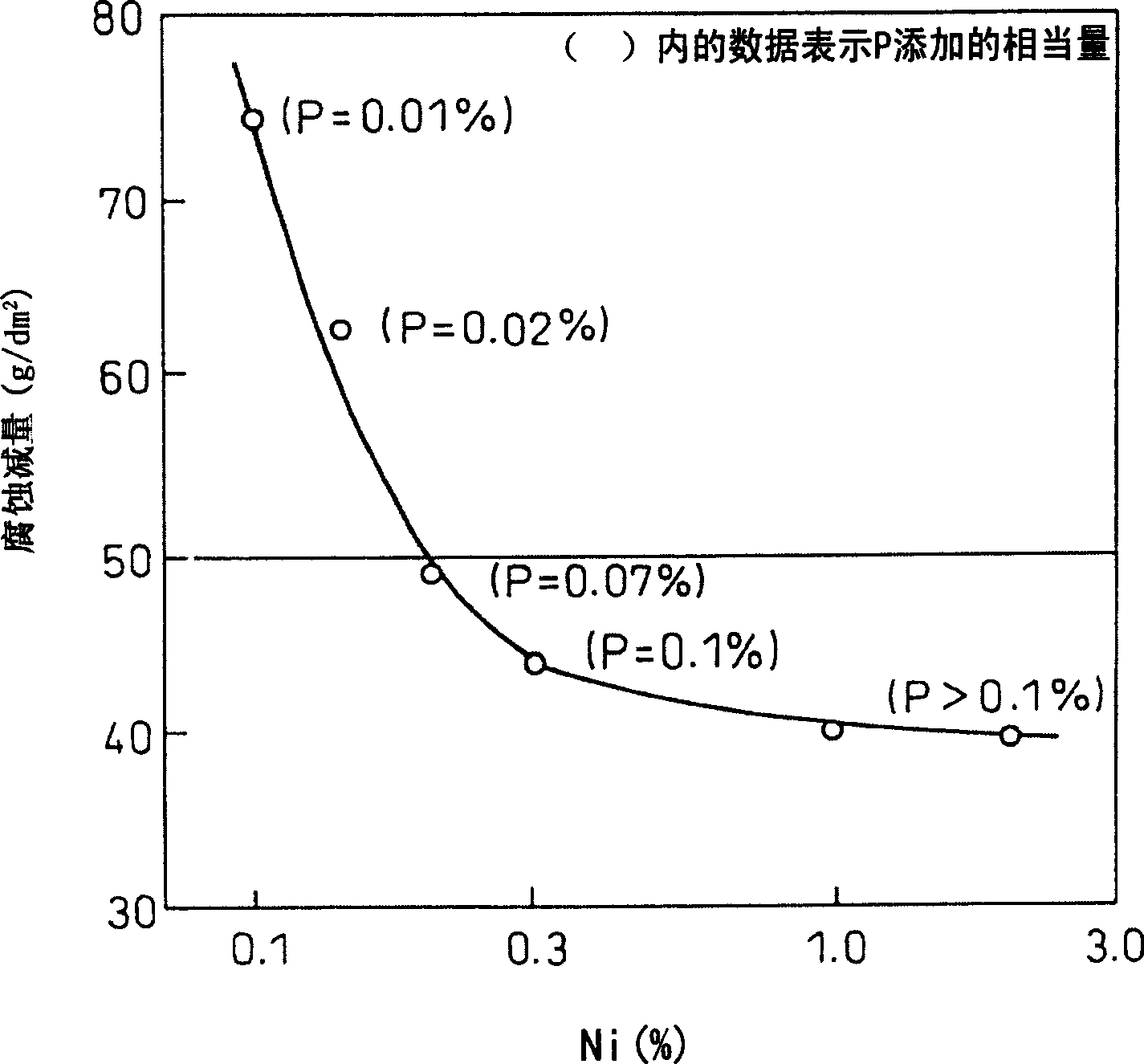

[0046] Weldability was judged by the presence or absence of cracks in the welded portion after arc welding. Weather resistance is a corrosion-promoting test in which wetting and drying are repeated after salt spray treatment, and the weight of the sample before the test and the weight of the sample after the test with rust removed are measured to obtain the corrosion loss. As a comparison, based on the data of commercially availabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com