Manufacturing method of integral herringbone gear shaft

A manufacturing method and gear shaft technology, applied in the field of gear shaft manufacturing, can solve problems such as expensive equipment, difficult maintenance, and precision errors, and achieve the effects of improving bending strength and reducing gear diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

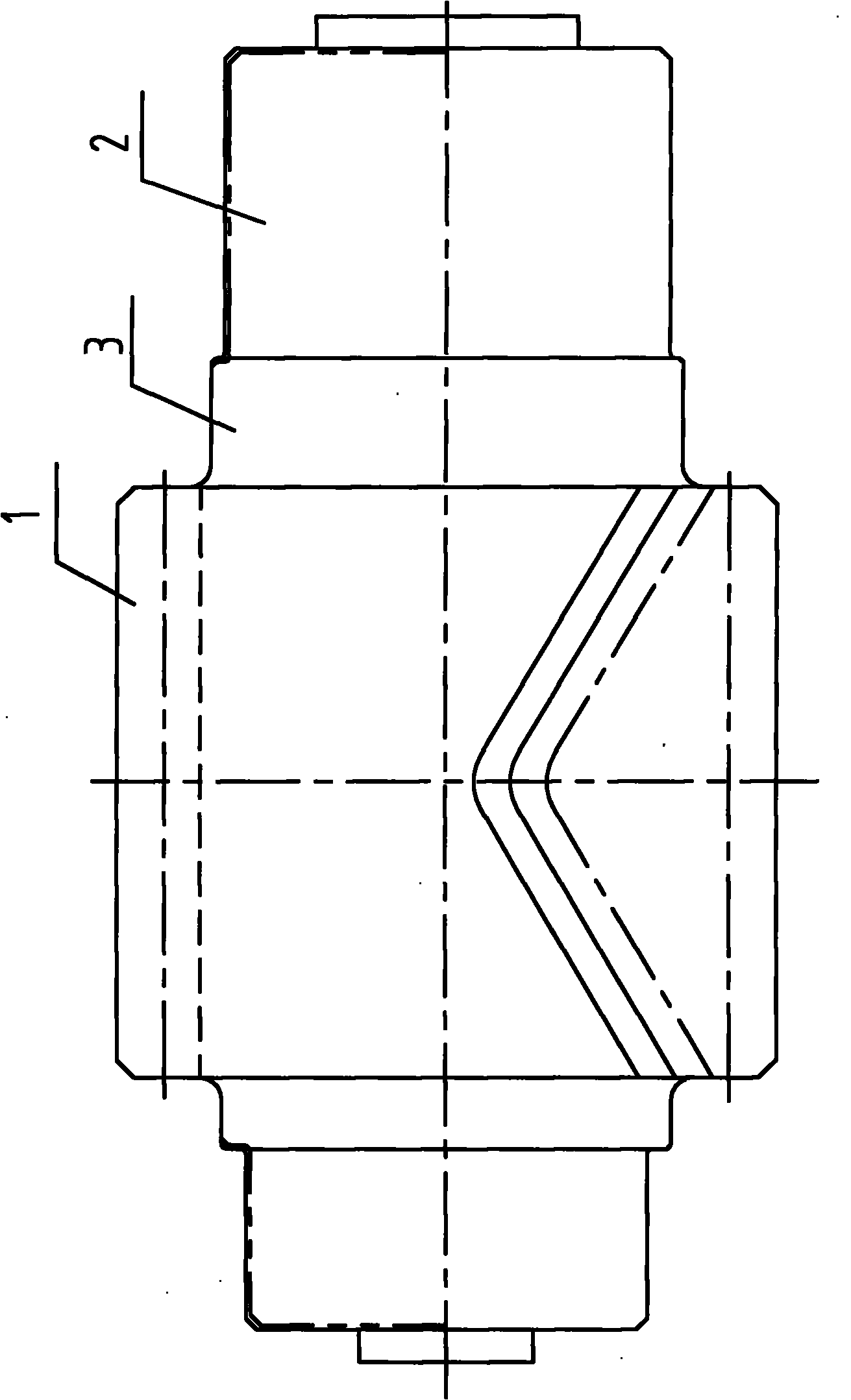

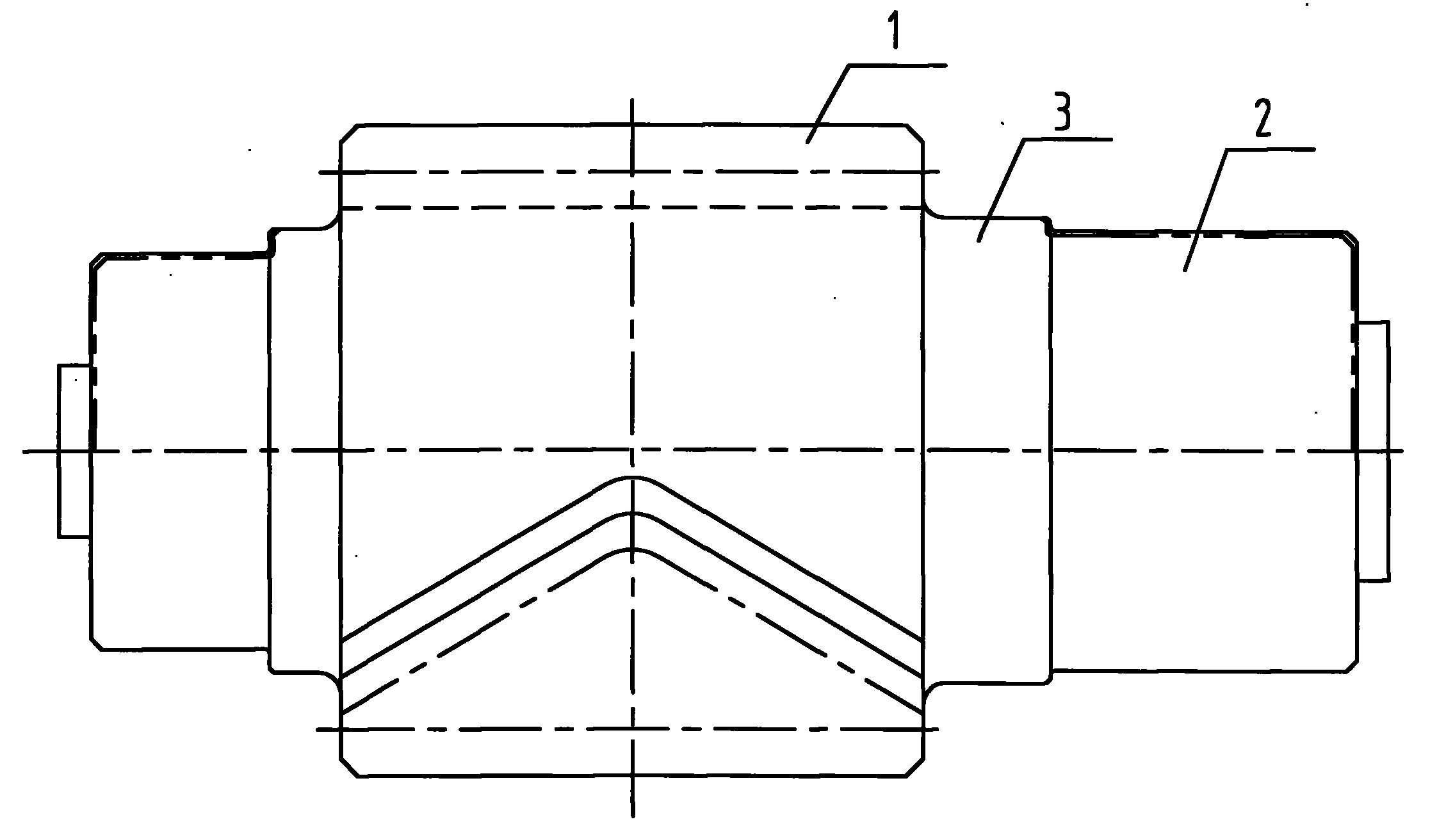

[0025] Such as figure 1 A specific embodiment of a manufacturing method of an integral herringbone gear shaft of the present invention is shown, including the following steps:

[0026] A. Material preparation: forging workpiece;

[0027] B. Use a drill press to drill the center hole at both ends of the workpiece;

[0028] C. The first car: Lathe the outer circle, end face and root R of each block lifting shoulder on the lathe to make the gear shaft 1, and leave a margin of 4mm on one side when turning the outer circle, and leave a margin of 4mm on one side when turning the end face. 24mm, turn the root R to the predetermined size, and chamfer;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brinell hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com