NiZn soft magnetic ferrite and preparation method thereof

A technology of soft magnetic ferrite and soft ferrite, which is applied in the field of nickel-zinc ferrite with high thermal shock resistance and its preparation, to achieve the effects of reducing material stress, increasing anisotropy constant, and optimizing crystal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

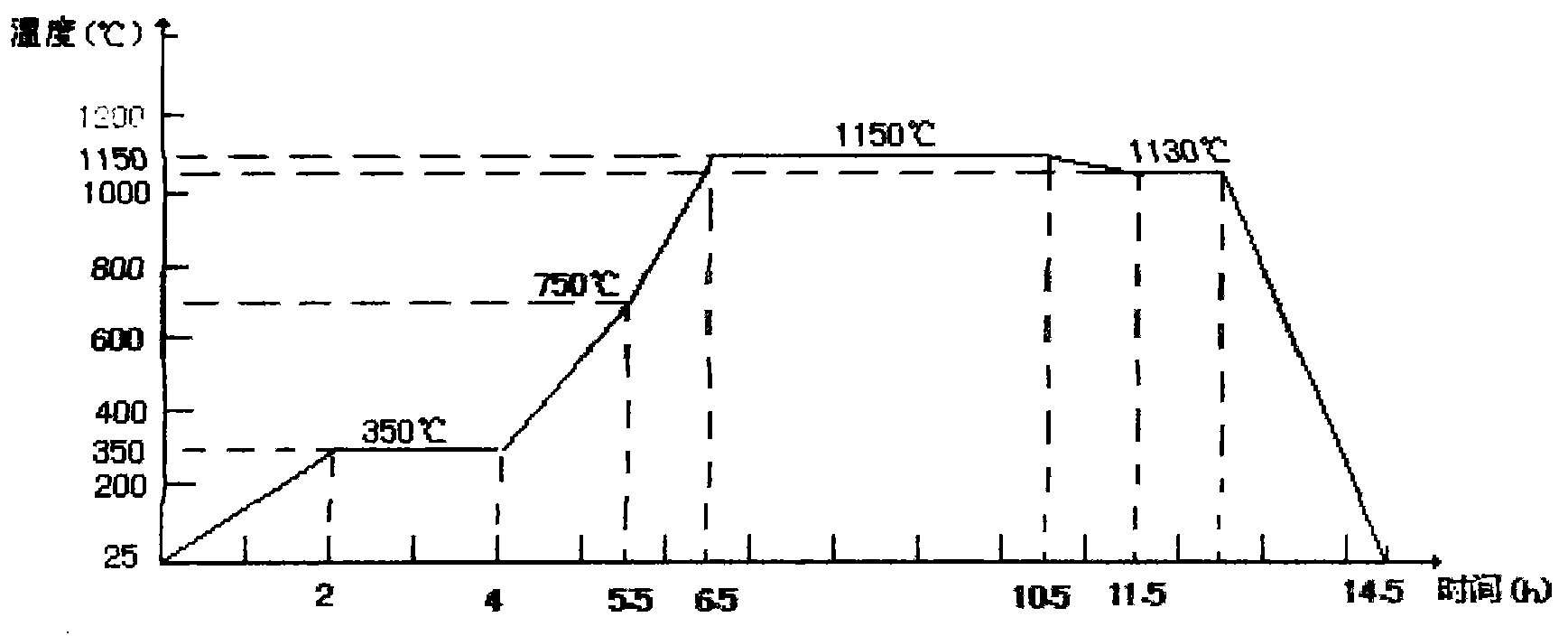

[0022] According to the invention figure 1 The shown sintering temperature curves embody the present invention, but the present invention is not limited to these examples.

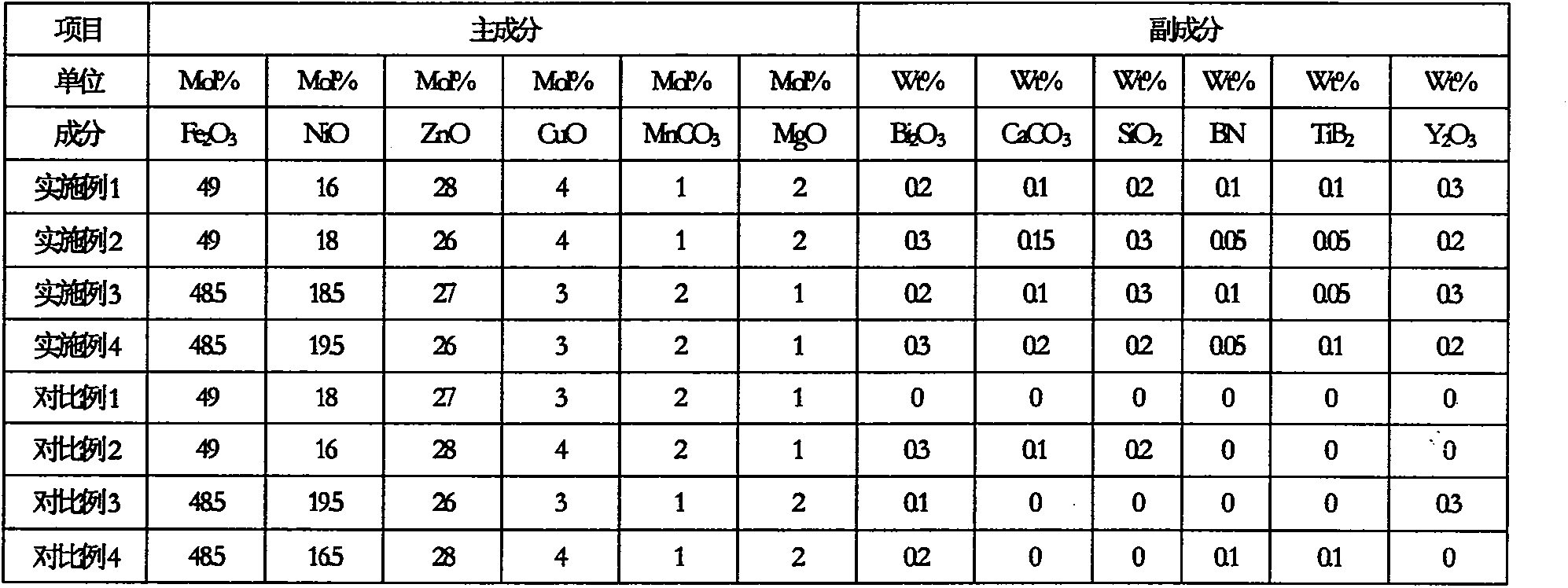

[0023] (1) Primary batching: take the raw material by weighing the composition ratio described in Table 1, the secondary component Bi 2 o 3 It is also added at the time of batching.

[0024] (2) Primary ball milling: dry milling in a vibration ball mill for 60-120 minutes.

[0025] (3) Pre-burning: The powder after primary ball milling is pre-fired in a pusher kiln at a temperature of 940±20°C and a holding time of 120-180 minutes.

[0026] (4) Secondary ingredients: add the selected de-Bi according to the ratio of the auxiliary ingredients 2 o 3 Other trace modifying elements.

[0027] (5) Secondary ball milling: The powder after secondary batching is subjected to wet ball milling for 5-8 hours, and the particle size of the slurry is controlled at 1-1.5 μm.

[0028] (6) Spray-drying granulation: ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com