High-hardness ceramic composite material of boron carbide-titanium boride-silicon carbide and preparation method thereof

A ceramic composite material and silicon carbide technology are applied in the field of boron carbide-titanium boride-silicon carbide high-hardness ceramic composite materials and their preparation, which can solve the problems that the hardness and toughness are difficult to improve at the same time, and the sintering temperature is high, and achieve fine grain size. , The effect of low sintering temperature and stable product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

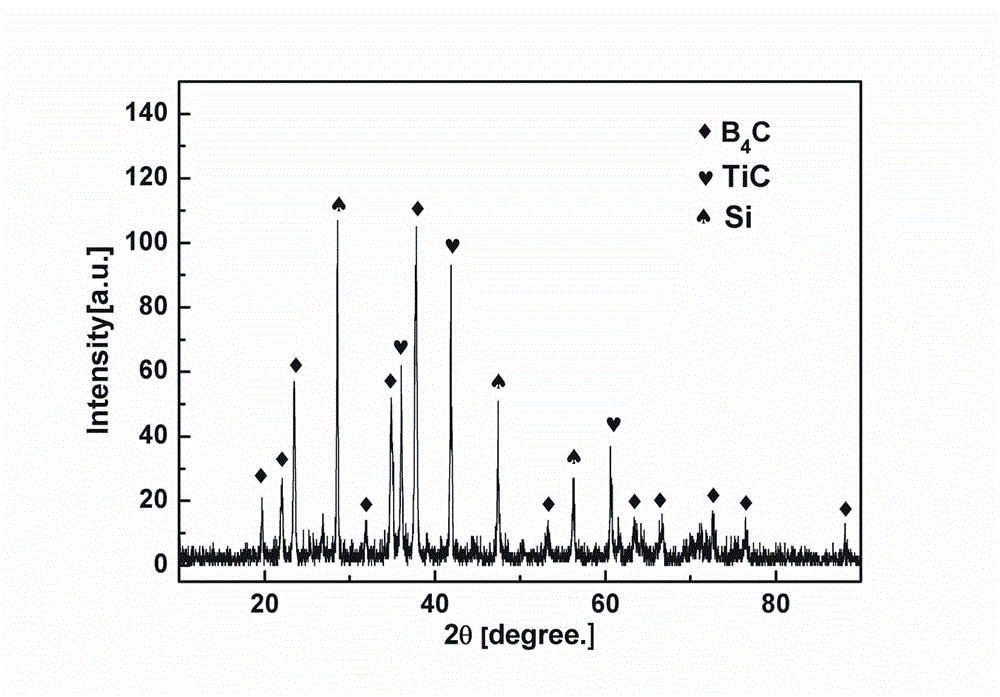

Embodiment 1

[0035]A boron carbide-titanium boride-silicon carbide high-hardness ceramic composite material is composed of 85%, 8.1% and 6.9% by mass of boron carbide, titanium boride and silicon carbide. It is sintered by ternary mixed powder of boron carbide, titanium carbide and silicon powder through reaction hot pressing technology. The ternary mixed powder includes 88.2% boron carbide powder (purity is 98% , with an average particle size of 0.8 μm), titanium carbide 6.9% (purity 97%, average particle size 1 μm), silicon powder 4.9% (purity 99%, average particle size 0.6 μm).

[0036] The preparation method of boron carbide-titanium boride-silicon carbide high-hardness ceramic composite material described in this embodiment, the specific steps include:

[0037] ①Weigh 88.2% of boron carbide powder, 6.9% of titanium carbide, and 4.9% of silicon powder by weight percentage;

[0038] ② Put the weighed powder into the ball mill tank of the planetary ball mill, add ethanol as the dispersi...

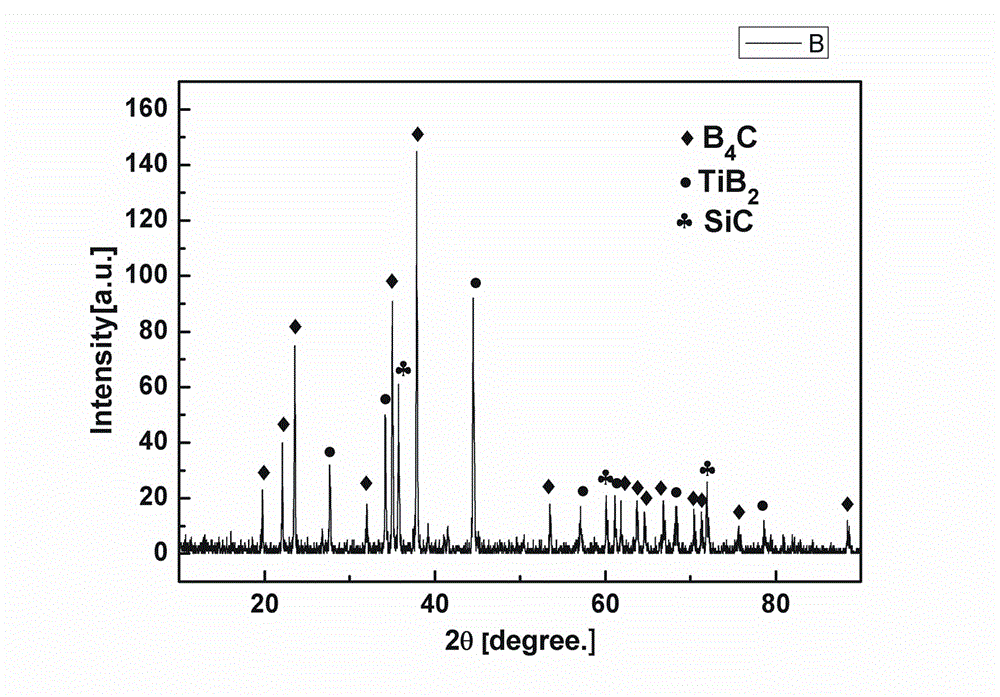

Embodiment 2

[0044] A boron carbide-titanium boride-silicon carbide high-hardness ceramic composite material is composed of boron carbide, titanium boride and silicon carbide with mass percentages of 90%, 5.4% and 4.6%. It is sintered by ternary mixed powder of boron carbide, titanium boride and silicon powder through reaction hot pressing technology. The ternary mixed powder of raw materials is calculated by weight percentage, including boron carbide powder 92.2% 96%, the average particle size is 3μm), titanium carbide 4.6% (purity is 97%, average particle size is 1μm), silicon powder is 3.2% (purity is 99%, average particle size is 2μm).

[0045] The preparation method of boron carbide-titanium boride-silicon carbide high-hardness ceramic composite material described in this embodiment, the specific steps include:

[0046] ① Weigh 92.2% of boron carbide powder, 4.6% of titanium carbide, and 3.2% of silicon powder by weight percentage;

[0047] ② Put the weighed powder into the ball mill...

Embodiment 3

[0052] The difference between this example and Example 2 is that the mass percentages of boron carbide, titanium boride and silicon carbide in the boron carbide-titanium boride-silicon carbide high-hardness ceramic composite material are 80%, 10.8%, 9.2% %.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com