Titanium boride-zirconium boride-silicon carbide self-lubricating composite ceramic material and preparation method thereof

A composite ceramic and zirconium boride technology, applied in the field of engineering materials, can solve the problems of low fracture toughness, low atomic self-diffusion coefficient, poor sintering performance, etc. The effect of increasing the number of worlds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

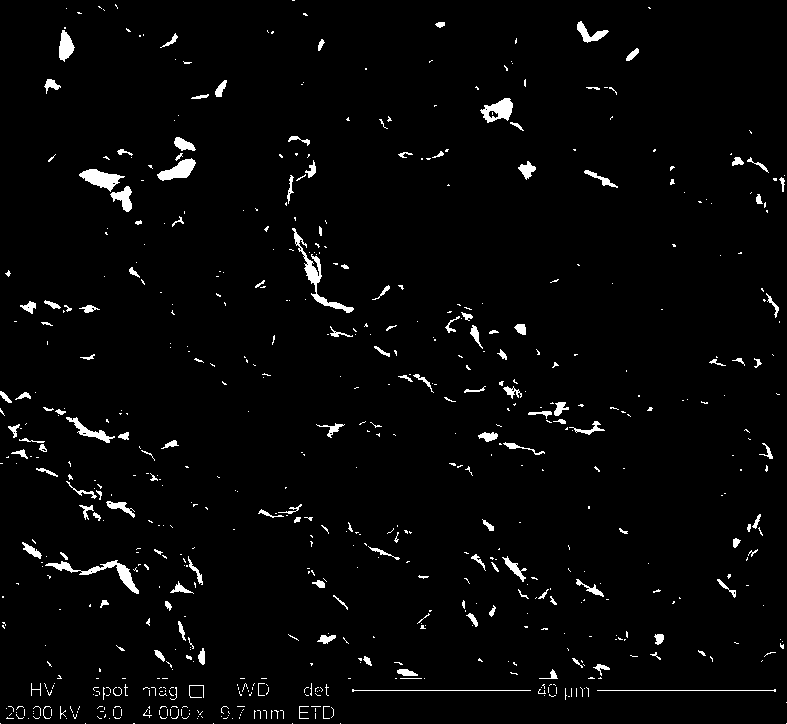

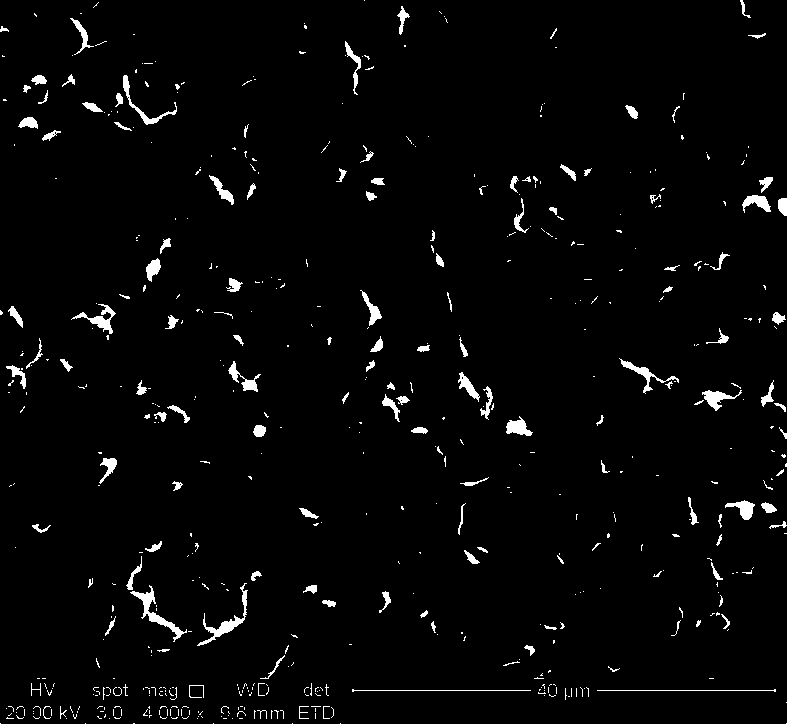

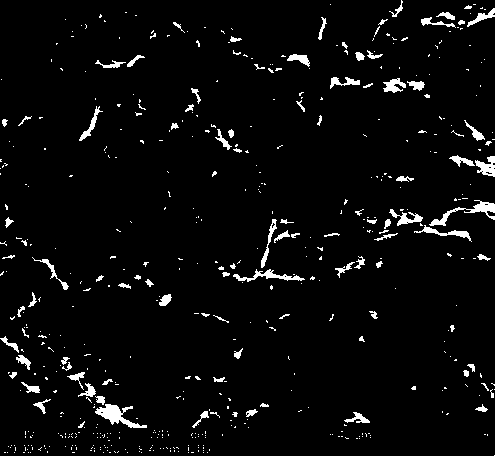

Image

Examples

Embodiment 1

[0033] A titanium boride-zirconium boride-silicon carbide self-lubricating composite ceramic material, the ceramic material is powdered TiB 2 As a matrix material, ZrB 2 It is the strengthening phase, SiC is the toughening phase ingredient, and the volume percentage of each component is: TiB 2 65.0%, ZrB 2 30.0%, SiC 5.0%.

[0034] A method for preparing the above-mentioned titanium boride-zirconium boride-silicon carbide self-lubricating composite ceramic material, comprising the following steps:

[0035] Step 1: Initial Ball Grinding

[0036] TiB 2 , ZrB 2 and SiC raw materials were put into ball milling tanks respectively, using absolute ethanol as the medium, ball milling for 90 hours, and then dried at 160°C for 22 hours and then sieved to obtain fine powder for later use;

[0037] Step 2: Batching, stirring and secondary ball milling

[0038] in TiB 2 65.0%, ZrB 2 30.0% and SiC 5.0% by volume, take the refined powder obtained in step 1 for preparation, pour ...

Embodiment 2

[0043] A titanium boride-zirconium boride-silicon carbide self-lubricating composite ceramic material, the ceramic material is powdered TiB 2 As a matrix material, ZrB 2 It is the strengthening phase, SiC is the toughening phase ingredient, and the volume percentage of each component is: TiB 2 55.0%, ZrB 2 40.0%, SiC 5.0%.

[0044] A method for preparing the above-mentioned titanium boride-zirconium boride-silicon carbide self-lubricating composite ceramic material, comprising the following steps:

[0045] Step 1: Initial Ball Grinding

[0046] TiB 2 , ZrB 2 and SiC raw materials were put into ball milling tanks respectively, using absolute ethanol as the medium, ball milling for 100 hours, and then dried at 150°C for 24 hours and then sieved to obtain fine powder for later use;

[0047] Step 2: Batching, stirring and secondary ball milling

[0048] in TiB 2 55.0%, ZrB 2 The volume percentage of 40.0%, SiC 5.0% is prepared by taking the refined powder obtained in ...

Embodiment 3

[0053] A titanium boride-zirconium boride-silicon carbide self-lubricating composite ceramic material, the ceramic material is powdered TiB 2 As a matrix material, ZrB 2 It is the strengthening phase, SiC is the toughening phase ingredient, and the volume percentage of each component is: TiB 2 85.0%, ZrB 2 10.0%, SiC 5.0%.

[0054] A method for preparing the above-mentioned titanium boride-zirconium boride-silicon carbide self-lubricating composite ceramic material, comprising the following steps:

[0055] Step 1: Initial Ball Grinding

[0056] TiB 2 , ZrB 2 and SiC raw materials were put into ball milling tanks respectively, using absolute ethanol as the medium, ball milling for 110 hours, then dried at 140°C for 26 hours, and then sieved to obtain fine powder, which was set aside;

[0057] Step 2: Batching, stirring and secondary ball milling

[0058] in TiB 2 85.0%, ZrB 2 10.0% and SiC 5.0% by volume, take the refined powder obtained in step 1 for preparation, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com