Anode material of lithium-ion battery

A sodium ion battery and negative electrode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low sodium intercalation capacity and poor cycle performance, and achieve high reversible capacity, good cycle performance, and good intercalation and desorption The effect of sodium capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The preparation of embodiment 1.Sn / acetylene black and electrochemical sodium storage performance

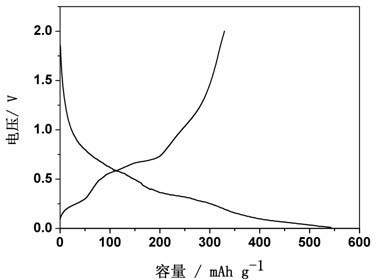

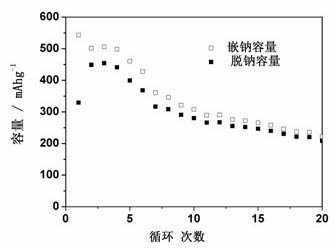

[0024] The commercialized Sn powder and acetylene black were mixed evenly according to the weight ratio of 70:30, and placed in a ball mill jar for ball milling for 8 hours to obtain the Sn / acetylene black composite material. With this material as the active material, the metal sodium sheet is the counter electrode, 1mol L -1 NaPF 6 (EC-DEC=1:1) Assembled the battery with the electrolyte to test its electrochemical performance, figure 1 is the first-cycle galvanostatic charge-discharge curve of the Sn / acetylene black composite, such as figure 1 shown at 100 mA g -1 Under the current density, the reversible capacity of the material is 329mAh g -1 , after 20 cycles, the capacity reached 221mAh g -1 (Such as figure 2 ).

[0025]

Embodiment 2

[0026] Embodiment 2. Preparation and electrochemical sodium storage performance of SbFe / acetylene black

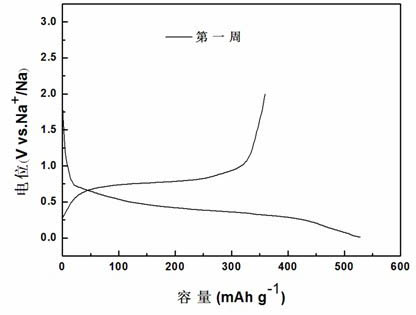

[0027] The commercial Sb powder, Fe powder and acetylene black were mixed evenly according to the weight ratio of 70:5:25, and placed in a ball mill jar for ball milling for 8 hours to obtain the SbFe / acetylene black composite material. With this material as the active material, the metal sodium sheet is the counter electrode, 1mol L -1 NaPF 6 (EC-DEC=1:1) Assembled the battery with the electrolyte to test its electrochemical performance, image 3 The first-cycle galvanostatic charge-discharge curves for the SbFe / acetylene black composite, as image 3 shown at 100 mA g -1 Under the current density, the reversible capacity of the material is 350mAh g -1 , after 90 cycles, the capacity reached 410mAh g -1 (Such as Figure 4 ).

[0028]

Embodiment 3

[0029] Embodiment 3. Preparation and sodium storage performance of SnSb / polypyrrole

[0030] Weigh Sn powder and Sb powder according to the mass ratio of 1:1 and mix them evenly, heat them at 500°C for 2 hours in a high-purity argon atmosphere to form a SnSb alloy, then weigh the SnSb alloy and polypyrrole according to the mass ratio of 7:3, and planetary ball mill for 60 minutes Get the required materials. A battery was assembled according to the method in Example 1 for electrochemical testing. at 100mAg -1 Current density, charging and discharging in the range of 0-2.0V, the measured reversible capacity in the first week is 450mAhg -1 , 82% of the initial capacity was still maintained after 20 weeks of circulation.

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com