Boron carbide-titanium boride multiphase ceramic material and pressureless sintering preparation method thereof

A technology of composite ceramics and titanium boride, applied in the field of structural ceramics, can solve the problems that restrict the popularization and application of boron carbide ceramic materials, complex production equipment, and little improvement in toughness, so as to improve the degree of densification, reduce the cost of raw materials, and promote The effect of the sintering process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] a B 4 C-TiB 2 A pressureless sintering preparation method of a multiphase ceramic material, the method steps are as follows:

[0039] (1) 50g of boron carbide powder (purity ≥ 90%, D 50 10μm), titanium boride powder 10g (purity ≥ 99%, D 50 10μm), amorphous carbon powder 10g (purity ≥ 99%, D 50 500nm), silicon powder 30g (purity ≥ 96%, D 50 1 μm), 200ml of dehydrated ethanol; put it into a nylon tank, ball mill on a planetary ball mill (ball-to-material ratio 1:1), ball mill speed 450r / min, ball milling time 48h; get mixed slurry;

[0040] (2) Dry the mixed slurry on a rotary evaporator, then dry in an oven for 12 hours; grind in a mortar, pass through a 100-mesh sieve to obtain a powder;

[0041] (3) The powder is dry-pressed into a graphite mold, and subjected to cold isostatic pressing, with a pressure of 500 MPa and a holding time of 5 minutes to obtain a green body;

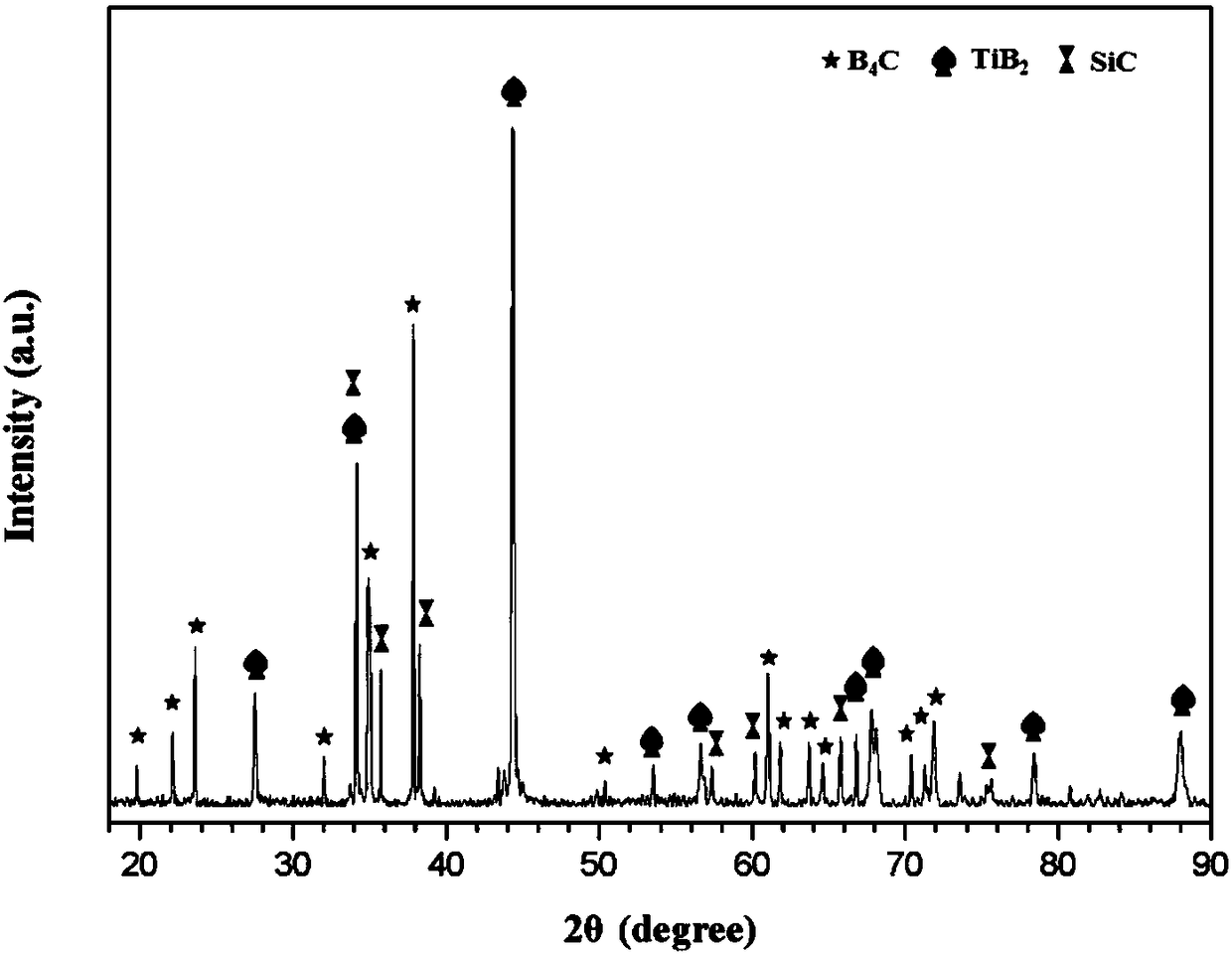

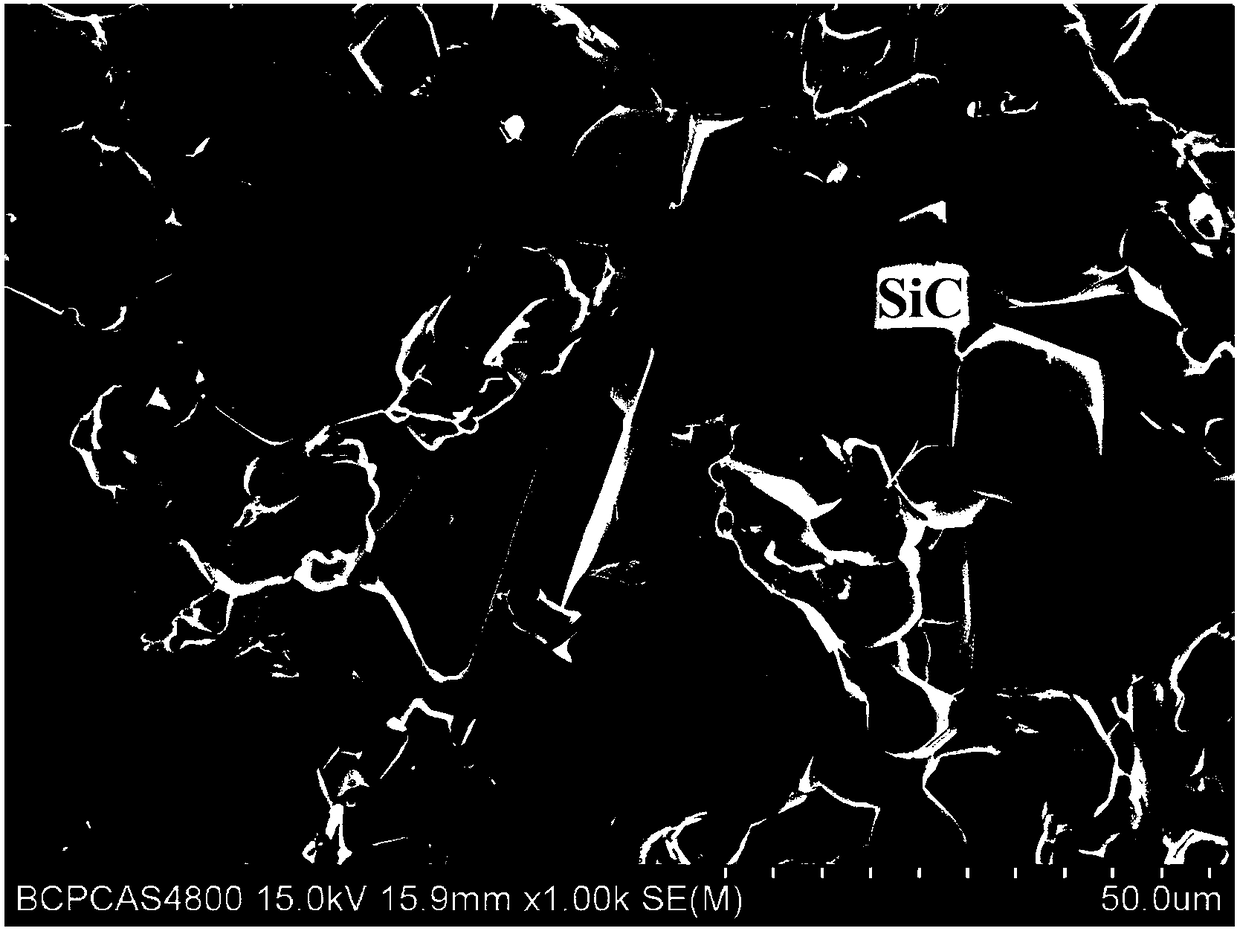

[0042] (4) Put the green body into a graphite vacuum sintering furnace for sintering at a sin...

Embodiment 2

[0047] a B 4 C-TiB 2 A pressureless sintering preparation method of a multiphase ceramic material, the method steps are as follows:

[0048] (1) 80g of boron carbide powder (purity ≥ 99%, D 50 3μm), titanium boride powder 10g (purity ≥ 95%, D 50 10μm), amorphous carbon powder 5g (purity ≥ 96%, D 50 3μm), silicon powder 5g (purity ≥ 96%, D 50 3 μm), 30 ml of absolute ethanol; put it into a nylon tank, and ball mill on a planetary ball mill (ball-to-material ratio 10:1), ball mill speed 80r / min, ball milling time is 12h; obtain mixed slurry;

[0049] (2) Dry the mixed slurry on a rotary evaporator, then dry in an oven for 36 hours; grind in a mortar, pass through a 60-mesh sieve to obtain a powder;

[0050] (3) The powder is dry-pressed into a graphite mold, and subjected to cold isostatic pressing, with a pressure of 100 MPa and a holding time of 30 minutes to obtain a green body;

[0051] (4) Put the green body into a graphite vacuum sintering furnace for sintering at a ...

Embodiment 3

[0056] a B 4 C-TiB 2 A pressureless sintering preparation method of a multiphase ceramic material, the method steps are as follows:

[0057] (1) 60g of boron carbide powder (purity ≥ 96%, D 50 5μm), titanium boride powder 30g (purity ≥ 95%, D 50 3μm), amorphous carbon powder 3g (purity ≥ 99%, D 50 300nm), silicon powder 7g (purity ≥ 99%, D 50 500nm), dehydrated ethanol 200ml; put it into a nylon tank, ball mill on a planetary ball mill (ball-to-material ratio 1:1), ball mill speed 300r / min, ball milling time 8h; obtain mixed slurry;

[0058] (2) Dry the mixed slurry on a rotary evaporator, and then dry it in an oven for 24 hours; grind it in a mortar, and pass through an 80-mesh sieve to obtain a powder;

[0059] (3) The powder is dry-pressed into a graphite mold, and subjected to cold isostatic pressing, with a pressure of 300 MPa and a holding time of 20 minutes to obtain a green body;

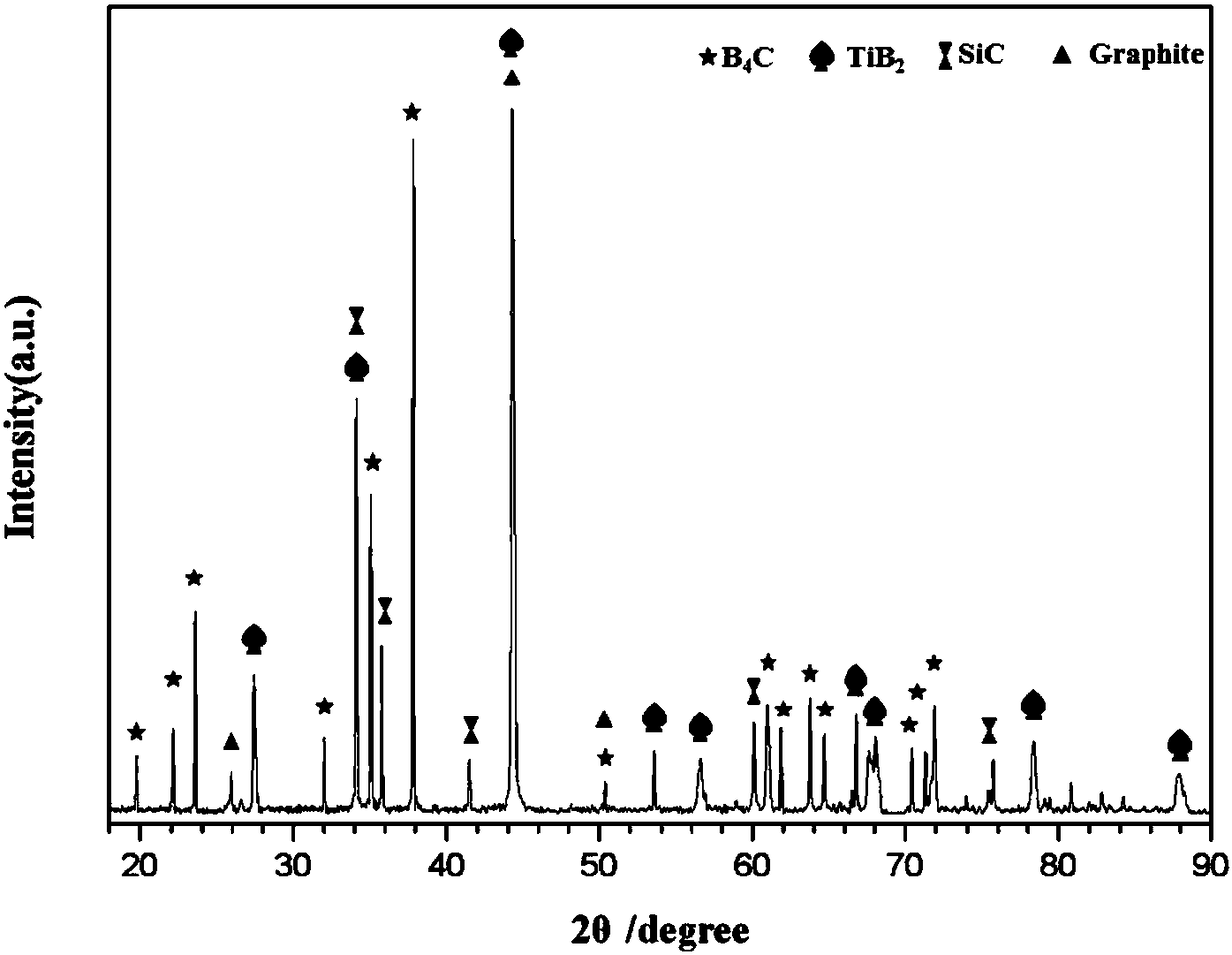

[0060] (4) Put the green body into a graphite vacuum sintering furnace for sinteri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com