Preparation process of odorless phosphate flame retardant

A preparation process, a technology for phosphate esters, applied in the directions of phosphorus organic compounds, compounds of elements of Group 5/15 of the periodic table, chemical/physical/physical chemical processes using energy, etc. The aldehyde deodorization process cannot effectively solve the problem of the odor of phosphate ester flame retardants, and achieves the effect of good separation of impurities, avoidance of side reactions and short residence time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

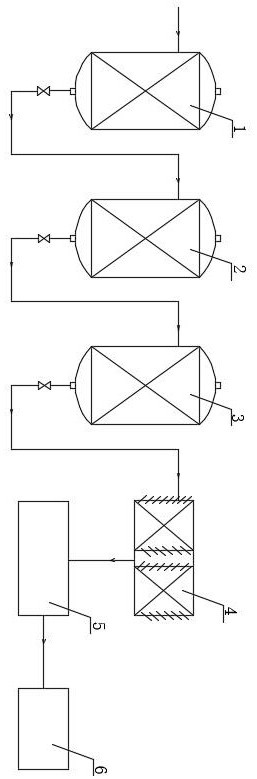

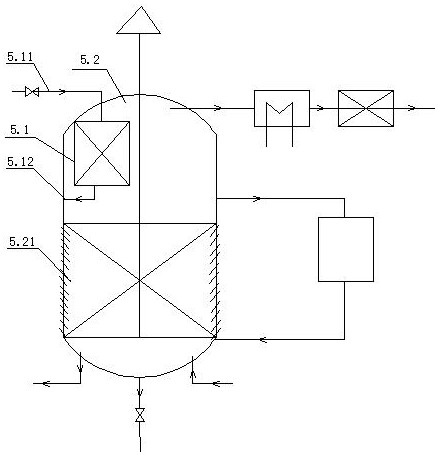

Method used

Image

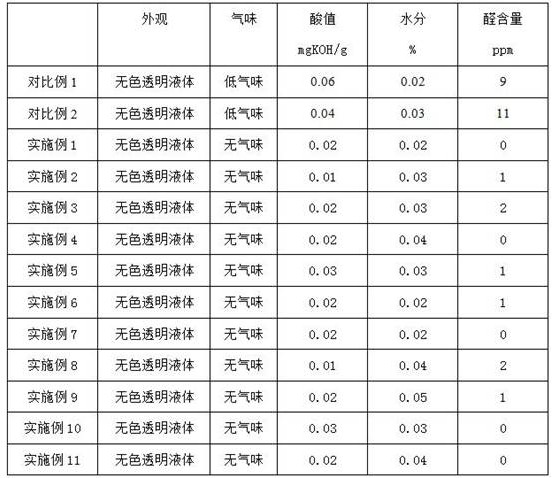

Examples

Embodiment 1

[0035] When working, put 153.33kg of phosphorus oxychloride into the crude product synthesis kettle, add 3.5kg of catalyst titanium tetrachloride after nitrogen replacement, slowly raise the temperature to 42°C and start feeding propylene oxide, and control the reaction temperature at 42±2°C, The input amount of propylene oxide was 179.1kg. After the input of propylene oxide was completed, it was incubated at 42°C for 1 hour, then vacuumed to -0.095mPa and kept at -0.095mPa for 1 hour to obtain the crude product.

[0036] Transport the crude product to the alkaline washing tank and add lye with a mass concentration of 10%. After adjusting the pH of the crude product to 7.5, transport it to the washing tank and add 33.2kg of water. After washing for 1 hour, let it stand for liquid separation once, remove the upper layer of washing liquid, and keep the lower layer product. Then add 33.2kg of water, wash with water for 1 hour, then let stand to separate the liquid, remove the was...

Embodiment 2

[0039] Put 153.33 kg of phosphorus oxychloride into the crude product synthesis kettle, add 3.9 kg of catalyst aluminum trichloride after nitrogen replacement, slowly raise the temperature to 45°C and start feeding propylene oxide, control the reaction temperature at 45±2°C, the input of propylene oxide The volume is 179.1kg. After the input of propylene oxide, heat preservation and aging at 45°C for 1h, then vacuumize to -0.098mPa, and keep the vacuum condition of -0.098mPa for 1h to obtain the crude product.

[0040] The crude product is transported to the caustic washing tank to add lye with a mass concentration of 20%. After the pH of the crude product is adjusted to 7.3, it is transported to the washing tank and added with 33.2 kg of water. Remove the lower layer of product. Then add 66.4kg of water, wash with water for 1 hour, then let stand to separate the liquid, remove the washing liquid in the upper layer, and keep the product in the lower layer. The lower layer pro...

Embodiment 3

[0043] Put 153.33kg of phosphorus oxychloride into the crude product synthesis kettle, add 3.0kg of catalyst boron trifluoride after nitrogen replacement, slowly raise the temperature to 50°C and start feeding propylene oxide, control the reaction temperature at 50±2°C, the input of propylene oxide The weight is 179.1kg. After the propylene oxide input is completed, heat preservation and aging at 50°C for 1h, and then vacuumize to -0.100mPa or MPA, and maintain the vacuum condition of -0.100mPa for 1h to obtain the crude product.

[0044] Transport the crude product to the alkaline washing tank and add lye with a mass concentration of 25%, adjust the pH of the crude product to 7.5, then transport it to the washing tank and add 39.2kg of water, wash for 1 hour and then separate the liquid once, remove the upper layer of washing liquid, and keep the lower layer product. Then add 39.2kg of water, wash with water for 1 hour, then let stand to separate the liquid, remove the washin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com