Battery pack temperature control/power feed system

A temperature control and power supply system technology, applied to secondary batteries, circuits, electrical components, etc., can solve the problems of not having the charging function of the battery itself, poor heating and cooling efficiency, and greatly increased costs to achieve cooling efficiency Excellent, improved battery life, and prevents damage from occurring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0154] Hereinafter, embodiments (examples) of the present invention will be described in more detail with reference to the drawings.

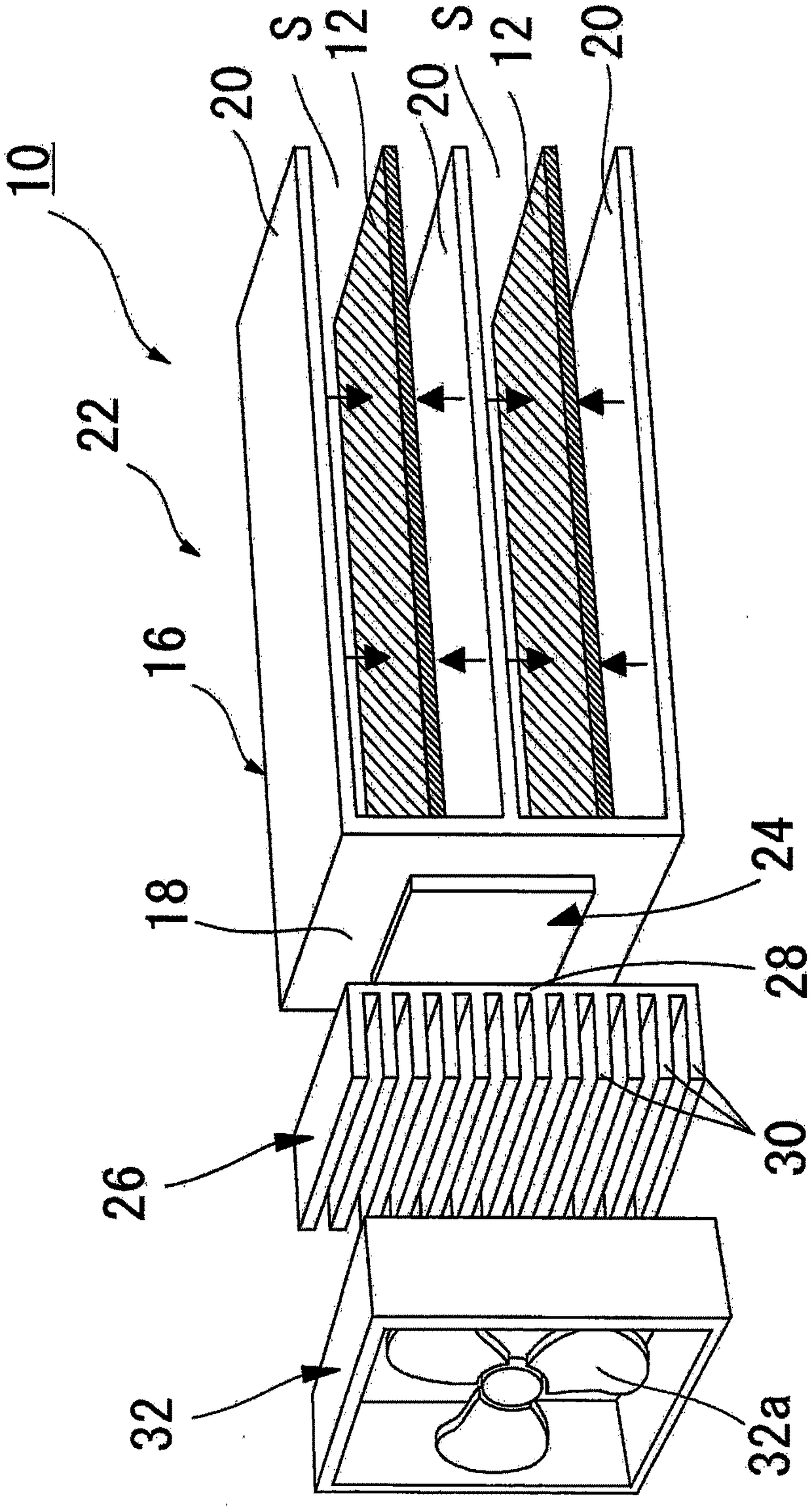

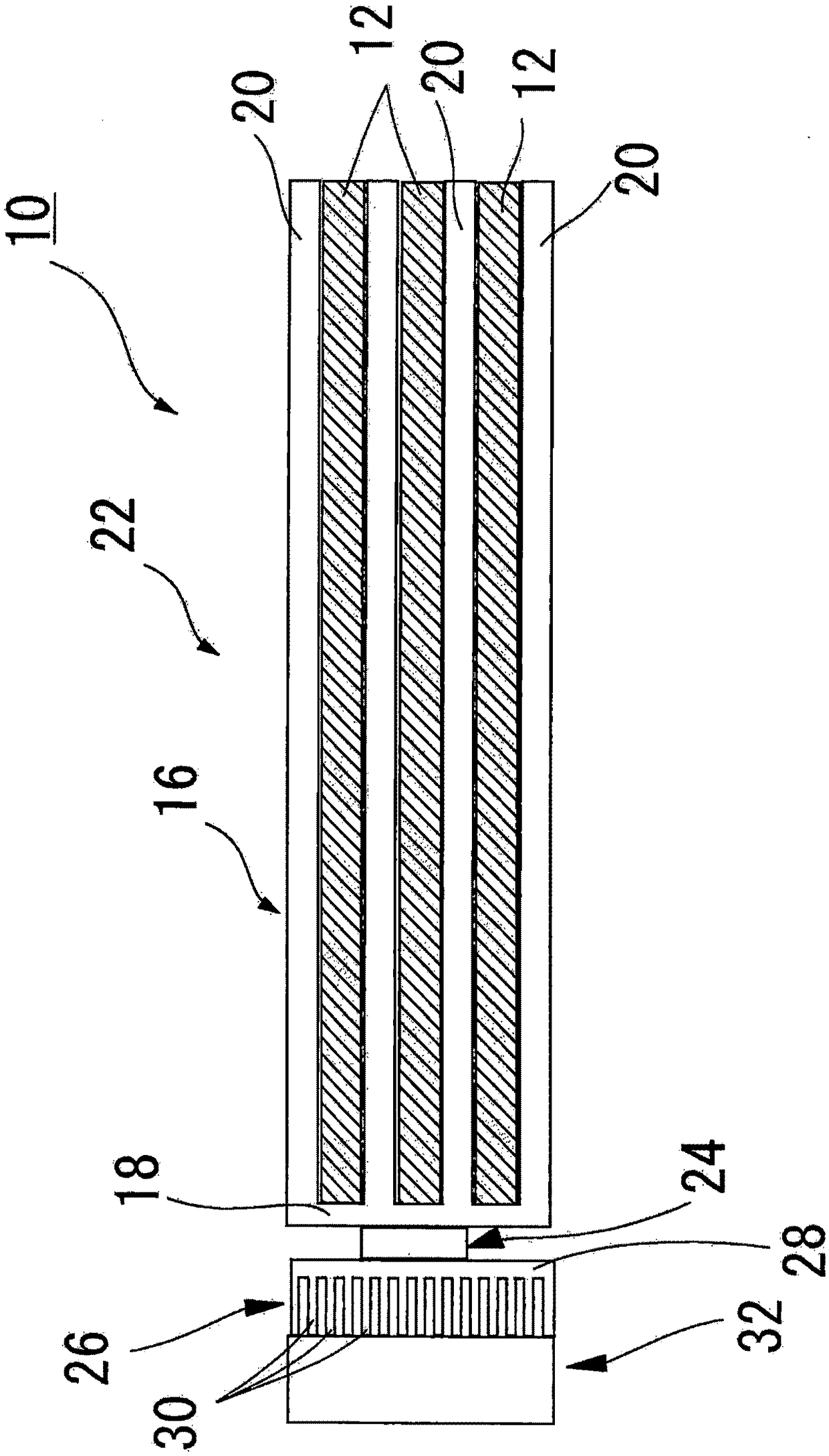

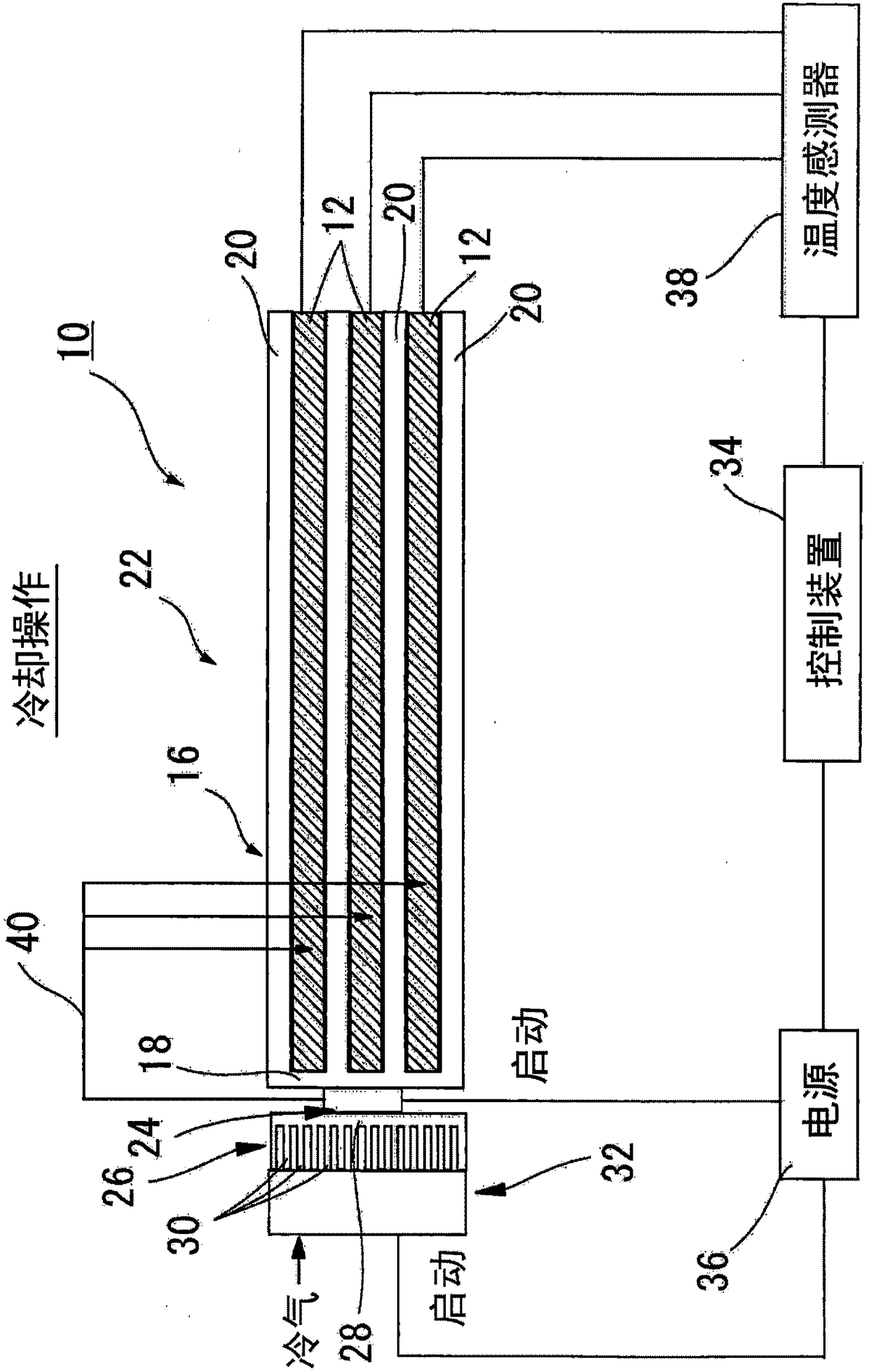

[0155] figure 1 It is a three-dimensional exploded view conceptually showing the battery pack temperature control and power supply system of the present invention, figure 2 for figure 1 The cross-sectional view of the temperature control and power supply system of the battery pack, image 3 A block diagram of the battery pack temperature control and power supply system for explaining the operating state of the battery pack temperature control and power supply system when the battery part is cooled in the present invention, Figure 5 A block diagram of the battery pack temperature control and power supply system for explaining the operating state of the battery pack temperature control and power supply system when the battery part is heated in the present invention, Figure 6 A block diagram of the battery pack temperature control and powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com