Method of treating hexane diacid preparation waste liquid

An adipic acid and waste liquid technology, applied in natural water treatment, chemical instruments and methods, extraction water/sewage treatment, etc., can solve the problems of large gas discharge, easy coking of products, dark color of products, etc., to reduce losses, Avoid sublimation or decomposition, the effect of low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

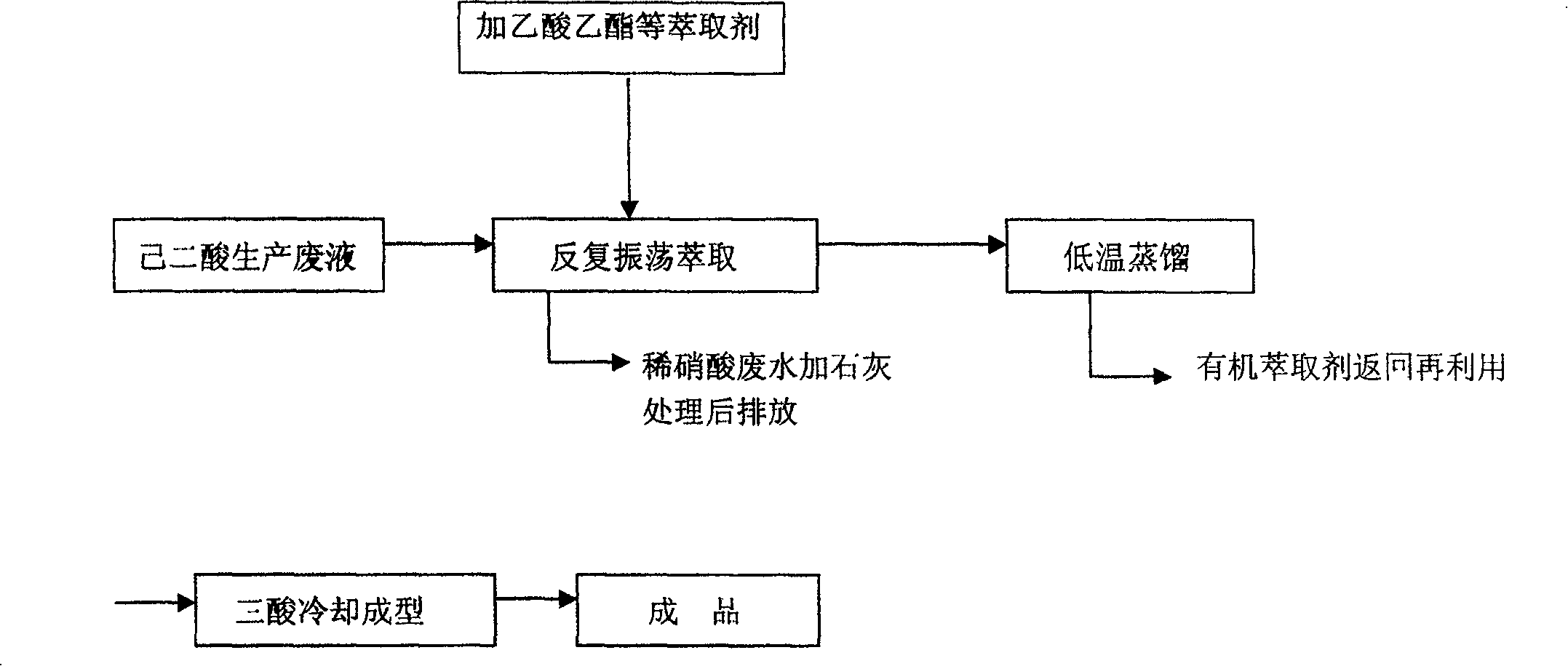

[0029] A method for processing adipic acid production waste liquid, comprising the steps of:

[0030] (1), take the adipic acid production waste liquid of V volume and the ethyl acetate extraction agent of V volume, add in the extraction equipment 1 together, under normal temperature and pressure, carry out vibration extraction, then static, when organic phase and aqueous phase After layering, the aqueous phase flows out from the extraction device 1, which is called 1b, and the remaining extract containing triacids (adipic acid, glutaric acid and succinic acid) is called 1a;

[0031] (2), then weigh V volumes of adipic acid production waste liquid, pour it into the extraction equipment 2, and then pour into the extract 1a containing triacids (adipic acid, glutaric acid and succinic acid) in a certain proportion , under normal temperature and pressure, carry out vibration extraction, then stand still, when the organic phase and the water phase are separated, the water phase flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com