Optical element processing method based on thermal accelerated corrosion

A technology for accelerating corrosion and optical components, applied in the polishing mechanism and grinding field, can solve the problems of high cost and low processing efficiency, and achieve the effects of low cost, high efficiency and improved material removal ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

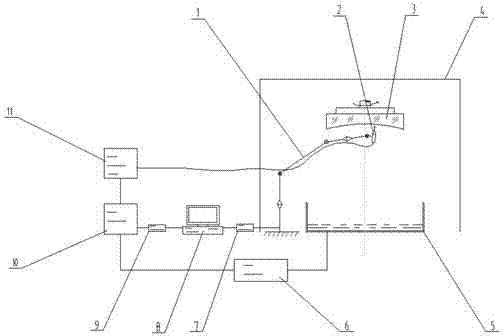

[0023] Such as figure 1 Shown: Jet polishing method based on thermally accelerated corrosion

[0024] Among them: 1 is the 6-axis industrial robot, 2 is the nozzle, 3 is the workpiece, 4 is the airtight chamber, 5 is the liquid storage device, 6 is the filter, 7 is the industrial robot controller, 8 is the industrial PC, 9 is the temperature Controller, 10 is a heating device, and 11 is a pump.

[0025] refer to figure 1 , the jet polishing method based on thermally accelerated corrosion adopts the method of turning the workpiece upside down and connecting it to the fixture. The workpiece is set on one side of the fixture, and the other side is fixedly connected to the rotating spindle; the corrosive liquid can realize closed-loop recycling. Pour the corrosive liquid suitable for the workpiece into the liquid storage device, pass through the filter, heating device and pump, and act on the workpiece through the nozzle, and then the corrosive liquid and the corroded workpiece ...

Embodiment 2

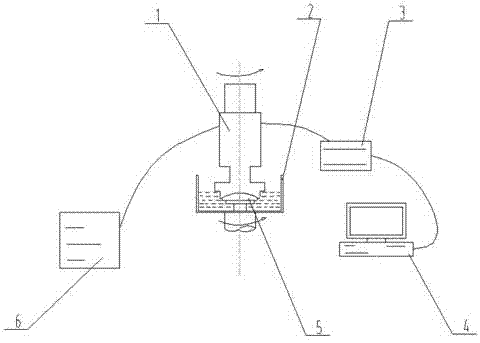

[0029] Such as figure 2 Shown: Corrosion Control Based Bladder Polishing Method

[0030] Among them: 1 airbag type polishing head, 2 corrosion liquid tank, 3 temperature control single chip microcomputer, 4 computer, 5 processed workpiece, 6 air pump.

[0031] refer to figure 2 , The airbag polishing method based on corrosion control uses an airbag polishing head, which is composed of a corrosion liquid tank installed on a single-axis machine, a temperature-controlled single-chip microcomputer, a computer, a workpiece to be processed, and an air pump. According to the different sizes and shapes of workpieces to be processed, select the corresponding air bag, install it on the polishing head, and start the air pump to the required pressure, so that the air bag can be in good contact with the workpiece. Pour the corrosive solution that matches the workpiece material to be processed into the corrosive solution tank. A ring-shaped heating wire is distributed on the inner surf...

Embodiment 3

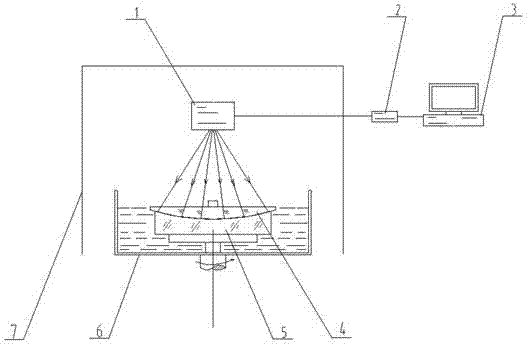

[0037] Such as image 3 Shown: Polishing method based on accelerated corrosion by radiation temperature field

[0038] Among them: 1 temperature field generating equipment, 2 controller, 3 computer, 4 transparent abrasive tool, 5 workpiece to be processed, 6 corrosive liquid storage tank, 7 closed environment.

[0039] refer to image 3 , the carrying mechanism makes all the processed components soaked in the corrosive liquid storage tank, the carrying mechanism is also equipped with a transparent abrasive, the polishing mold is made of transparent material, which is equivalent to the size of the workpiece to be processed; the temperature field generating device is connected with the control mechanism; the carrying Both the mechanism and the corrosive liquid storage tank are fixedly arranged on the rotating shaft. The temperature distribution radiation is determined by the temperature field generating equipment; the required balanced temperature field is realized by controll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com