Edible fungus drying room

A technology for edible fungi and drying room, which is applied in drying, dryer, lighting and heating equipment, etc., can solve the problems of destroying the application value of edible fungi, difficult and rapid temperature control, and poor thermal insulation effect, saving manpower and material resources. , Reduce heat loss, accurate drying process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further illustrated below in conjunction with the accompanying drawings and specific embodiments. This embodiment is implemented on the premise of the technical solution of the present invention. It should be understood that these embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

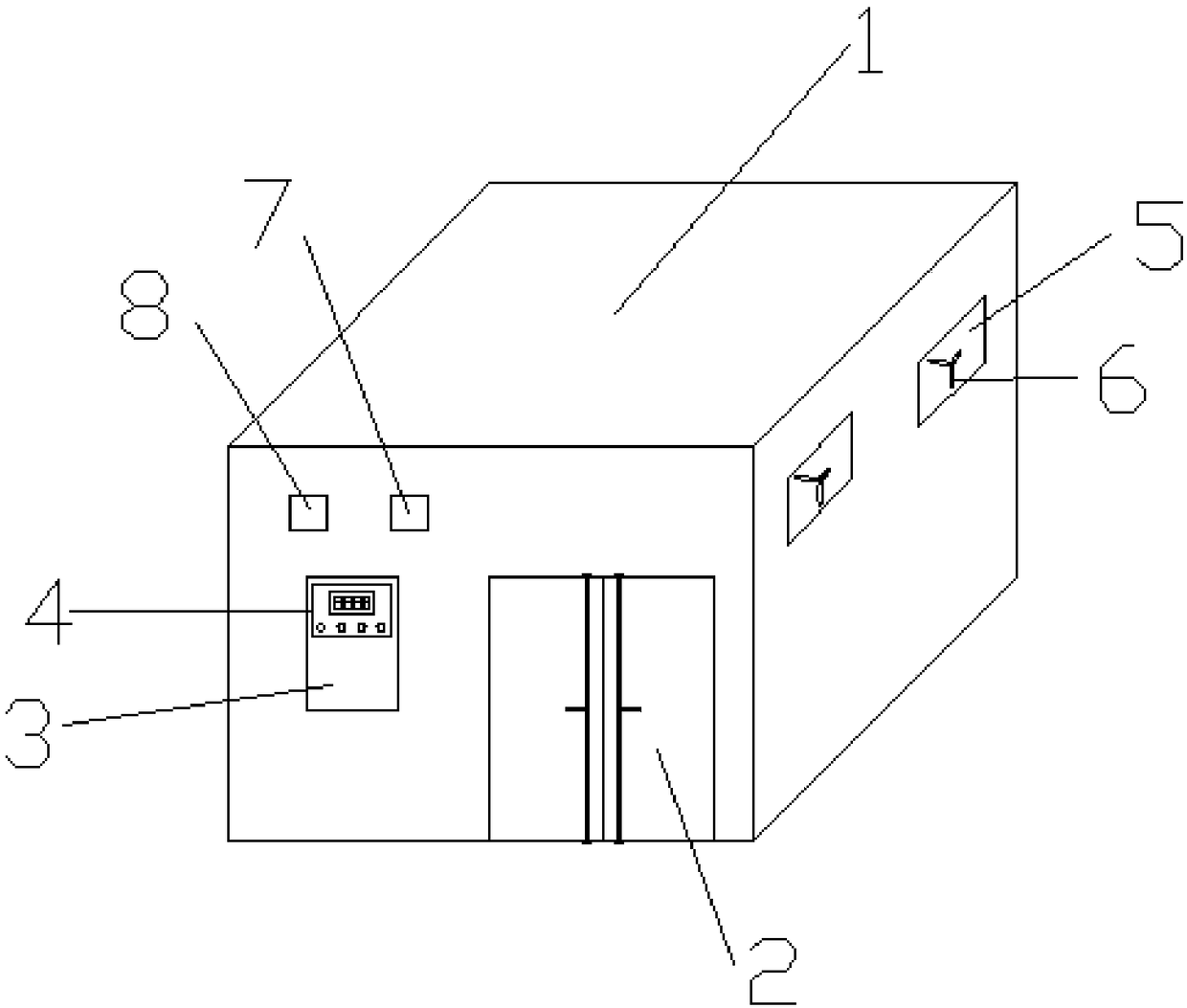

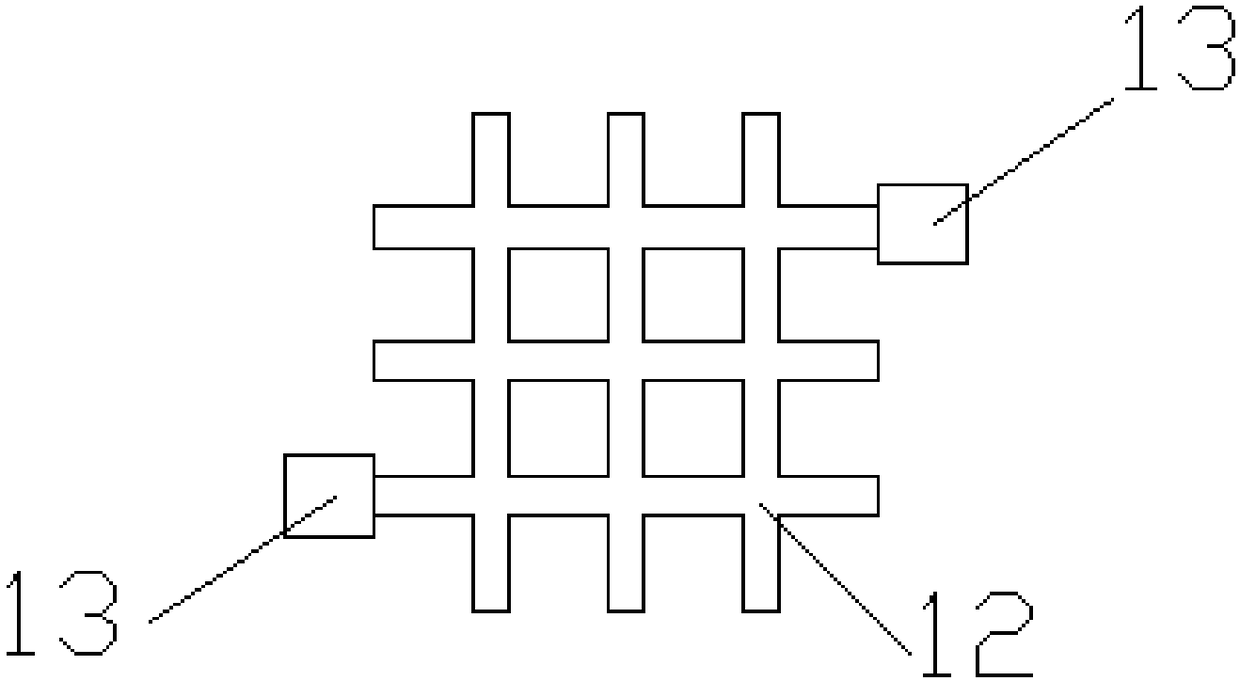

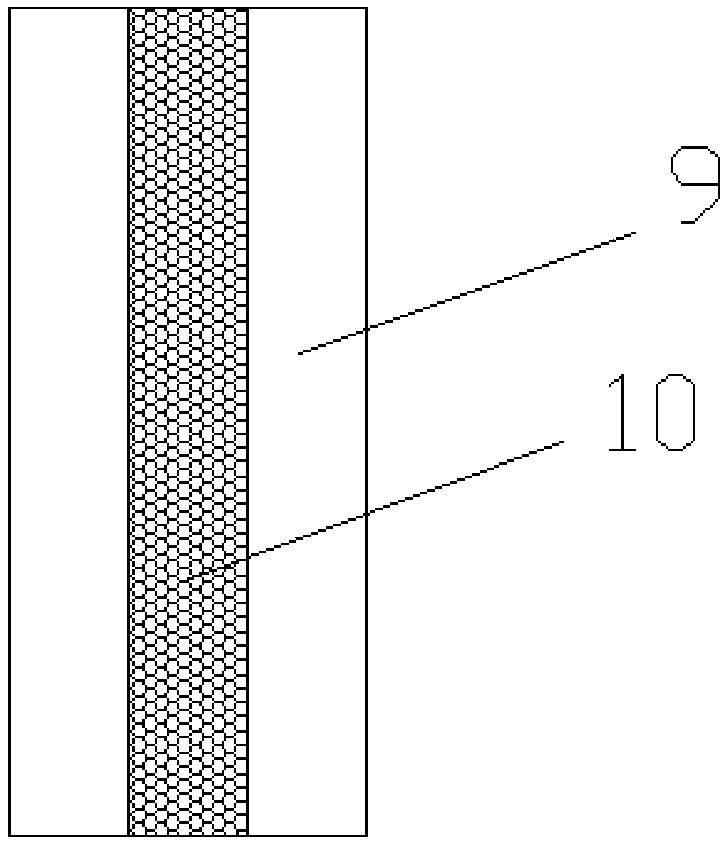

[0015] like figure 1 , figure 2 and image 3 Shown, a kind of edible fungus drying room, comprises house body 1, is provided with insulation layer 10 in the body of wall 9 interlayers of described house body 1; The drying rack is provided with a heating pipe 12, and the two ends of the bottom drying rack are provided with a heating device 13 connected to the heating pipe 12; Fan 6; a temperature sensor 7 and a humidity sensor 8 are arranged in the drying room; a door 2 and a transparent window 3 are provided on the outer wall of the drying room, and a control box 4 is arranged outsid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com