Airbag-type grinding-polishing device based on control corrosion

A control device and airbag technology, applied in the direction of grinding automatic control devices, manufacturing tools, grinding machine parts, etc., can solve the problems of high cost and low processing efficiency, and achieve low cost, no astigmatism and With poor, fast polishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

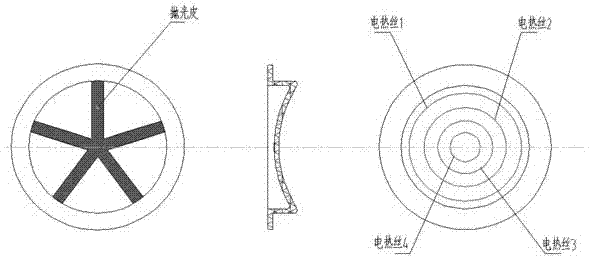

[0019] The invention is based on the principle of chemical corrosion, through the application of the temperature field to achieve the increase of corrosion rate and the removal of materials in different rings; different from the sub-aperture principle commonly used in aspheric surface processing, this invention is a conformal polishing technology, so that the aspheric surface The difficulty of processing is reduced to the difficulty of spherical processing; chemical corrosion will cause the surface roughness of the workpiece to deteriorate, and the present invention adds an airbag-type mechanical polishing device to obtain a smooth surface.

[0020] The invention is suitable for rapid grinding and polishing of plane, spherical and aspheric optical elements.

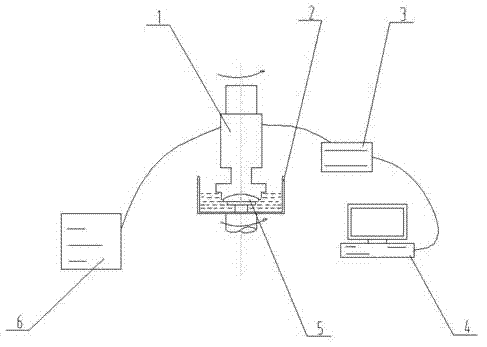

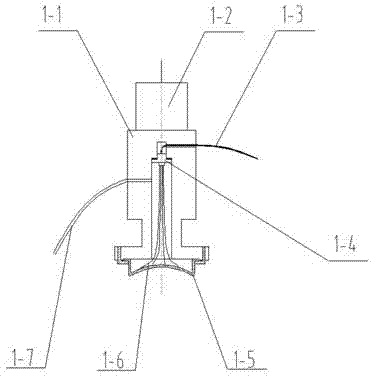

[0021] The airbag polishing device based on corrosion control includes an airbag polishing head 1, a corrosion liquid tank 2 installed on a single-axis machine, a temperature-controlled single-chip microcomputer 3, a compu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com