Controllable temperature and humidity environment box and control circuit

A technology of humidity control and environmental chamber, which is applied in the direction of non-electric variable control, control/regulation system, and simultaneous control of multiple variables, etc., and can solve problems such as single working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

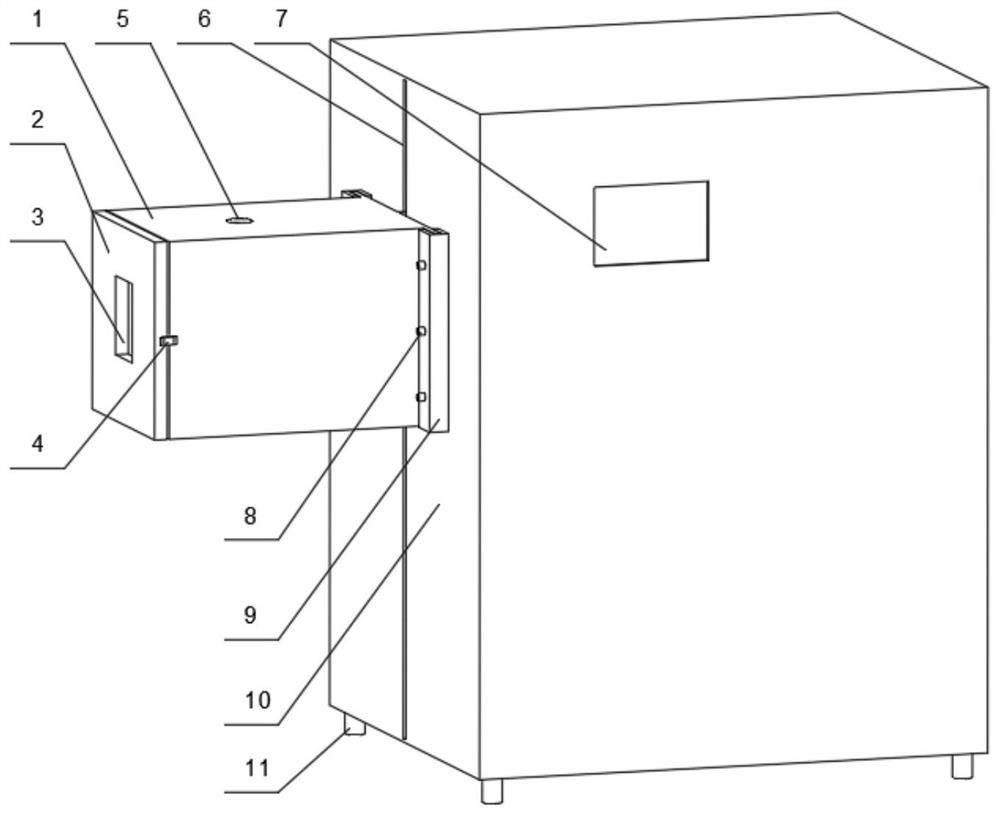

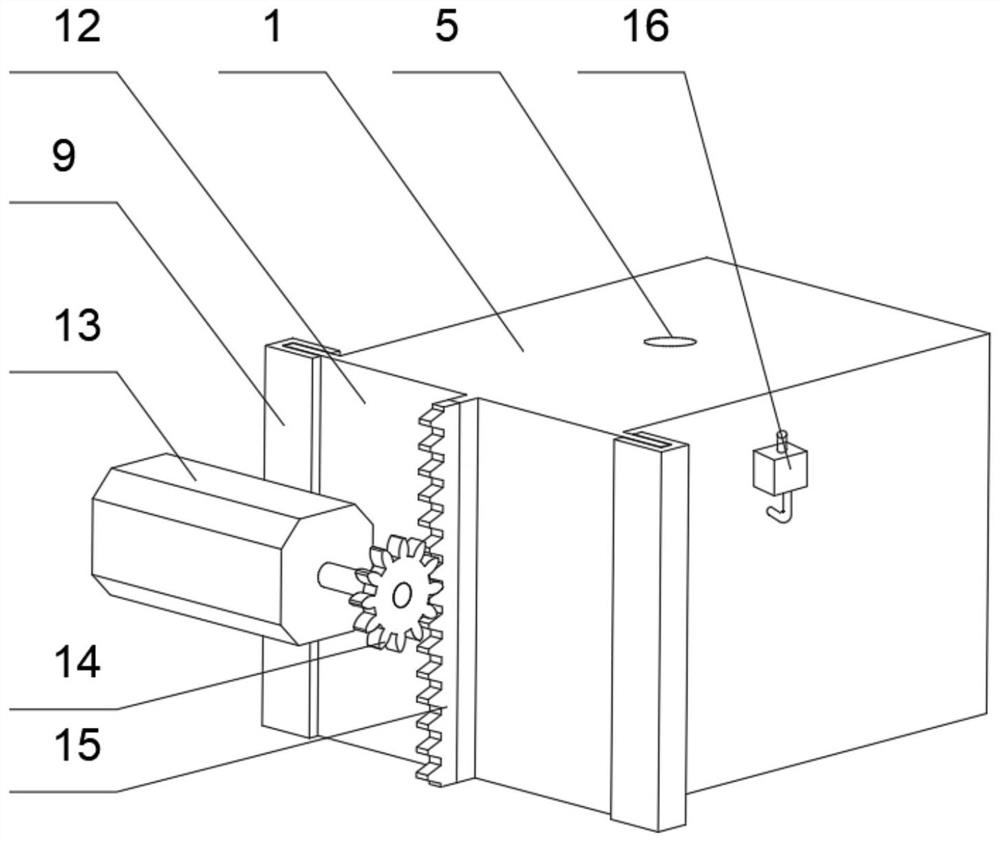

[0067] Such as figure 1 and figure 2 As shown, a controllable temperature and humidity environment box includes: a main environment box 1, a fixed support box 10, a motor 13, a high temperature control unit, a low temperature control unit, a humidity control unit, a control instrument panel 7, and a temperature and humidity meter 24 And fan 22; one side of the main environment box 1 is connected to the side of the fixed support box 10, and the fixed support box 10 is installed with a motor 13 near the inner wall of the main environment box 1 side, and the fixed support box 10 is connected to the motor 13 and passed through the motor 13 Adjust the height; install the high temperature control unit on the inner wall of the main environment box 1 close to the side of the fixed support box 10, install the low temperature control unit on the side of the main environment box 1 perpendicular to the fixed support box 10, and install the humidity control unit inside the fixed support b...

Embodiment 2

[0073] Embodiment 2 is a preferred example of Embodiment 1.

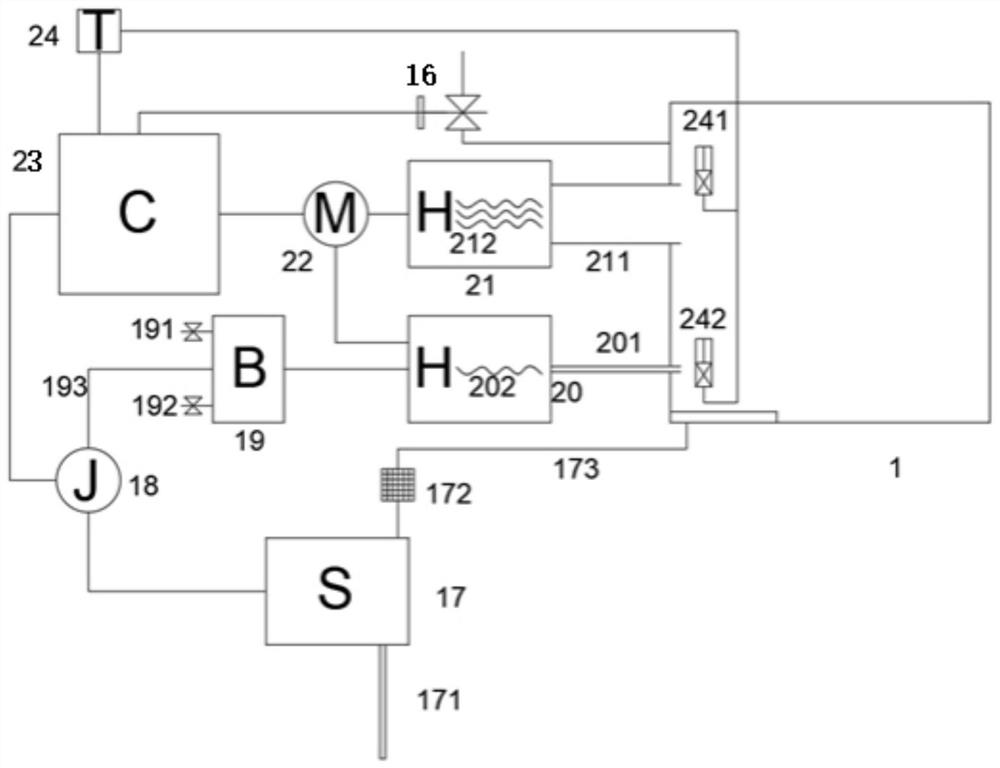

[0074]The high-temperature control unit includes a heater 21, a temperature sensor 241, a temperature-humidity meter 24, and a fan 22; the low-temperature control unit includes a liquid nitrogen inlet and outlet valve 16, a temperature sensor 241, a temperature-humidity meter 24, and a fan 22; Combination, drainage circuit, humidity sensor 242 and temperature and humidity meter 24. The main environmental box 1 has a cubic appearance, including the outer frame of the box, the inner cavity of the box and the switch door 2 of the environmental box. The fixed support box 10 is a floor-standing structure, which is used to fix and support the main environment box 1, and at the same time install the hardware facilities of the electronic control system inside. The electric control system integrates high temperature, low temperature, and humidity signals, and the control instrument panel 7 realizes test environment paramete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com