Double-control ventilation hood for oxidation desulfurization draught fan

A technology for oxidation fans and ventilation hoods, which is applied in the fields of sound insulation devices, fan noise reduction, and dual-control ventilation hoods. It can solve the problems of high temperature inside the hood, inconvenient maintenance, and poor sound insulation and noise reduction efficiency of the anechoic hood, so as to reduce noise. , The effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

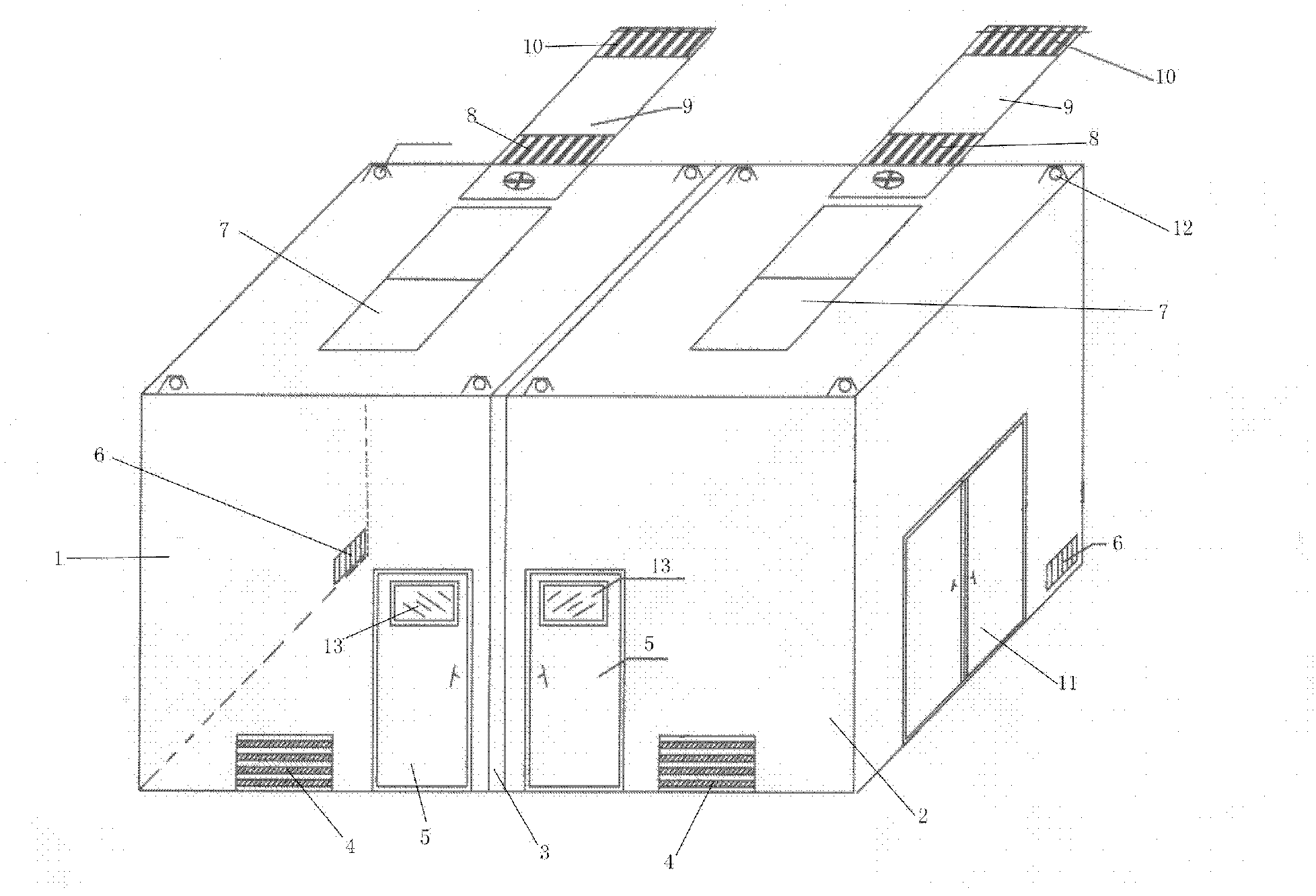

[0015] Such as figure 1 and figure 2 As shown, a double-control ventilation hood for desulfurization and oxidation fans of the present invention includes a first cover 1 and a second cover 2, wherein the first cover 1 and the second cover 2 Both are rectangular parallelepiped, the first cover body 1 and the second cover body 2 are arranged side by side, the opposite sides of the first cover body 1 and the second cover body 2 are open and communicated with each other, and the opposite sides of the first cover body 1 and the second cover body 2 The spacer bar 3 that is arranged between the front side wall of the first cover body 1 and the second cover body 2, the rear side wall and the top plate is connected, the rear side wall of the first cover body 1 and the rear side of the second cover body 2 The walls are respectively provided with a rear inlet muffler 4 and a single fan suction sound insulation door 5, and the left side wall of the first cover body 1 and the right side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com