Control method of medical sterilization packaging bag sealing machine

A control method and sealing machine technology, which is applied in the field of packaging bag sealing, can solve problems such as unstable temperature control and unreasonable structural layout, and achieve the effects of low temperature control, alleviating temperature overshoot, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

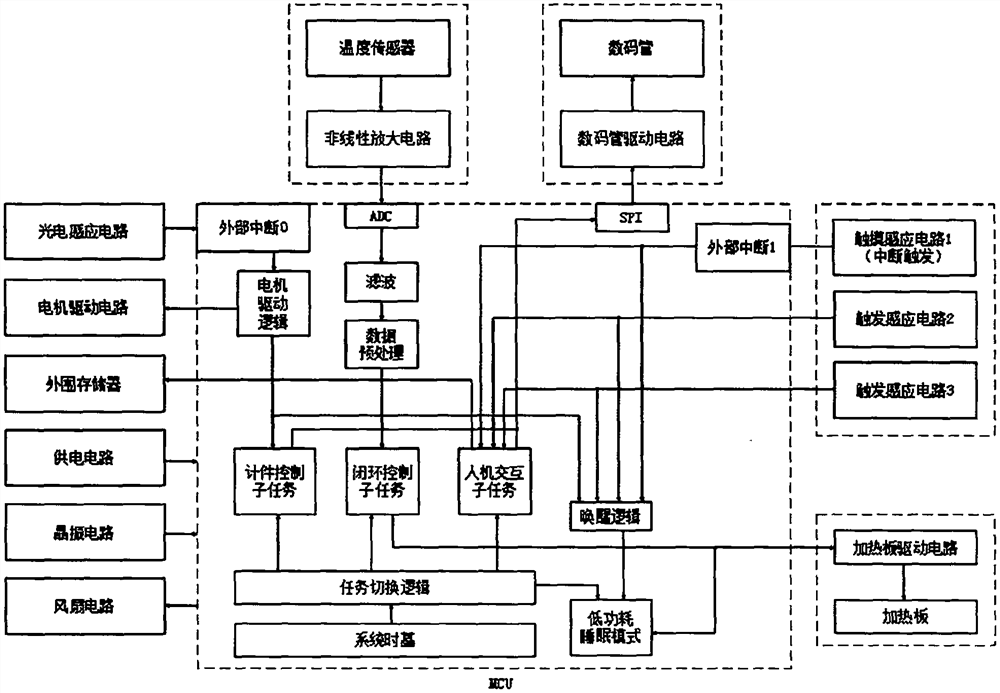

[0041] The control method described in the embodiment of the present invention is: after the power-on self-check, execute the closed-loop control subtask according to the parameters set during the last work, when the photoelectric sensor detects that the sterilized packaging bag passes, refresh the remaining time of the motor operation (If the motor is in a stopped state, start the motor and refresh the remaining time), and at the same time, the piece counting control task is suspended. After the closed-loop control single loop control is completed, jump to execute a piece counting task, and then unconditionally jump to execute the closed-loop control subtask. When the rising edge of the touch sensing circuit 1 arrives, turn off the heating plate and the motor, and jump directly to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com