Fast checking method for pipe defect and nondestructive testing apparatus

A non-destructive testing and pipeline technology, applied in the direction of ultrasonic/sonic/infrasonic generation, etc., can solve the problems of inability to judge the type, distribution, size of defects, poor quantitative detection effect, unsuitable for online detection, etc., and achieve a wide range of detection capabilities , reduce the intensity of manual inspection, and reduce the effect of maintenance scope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

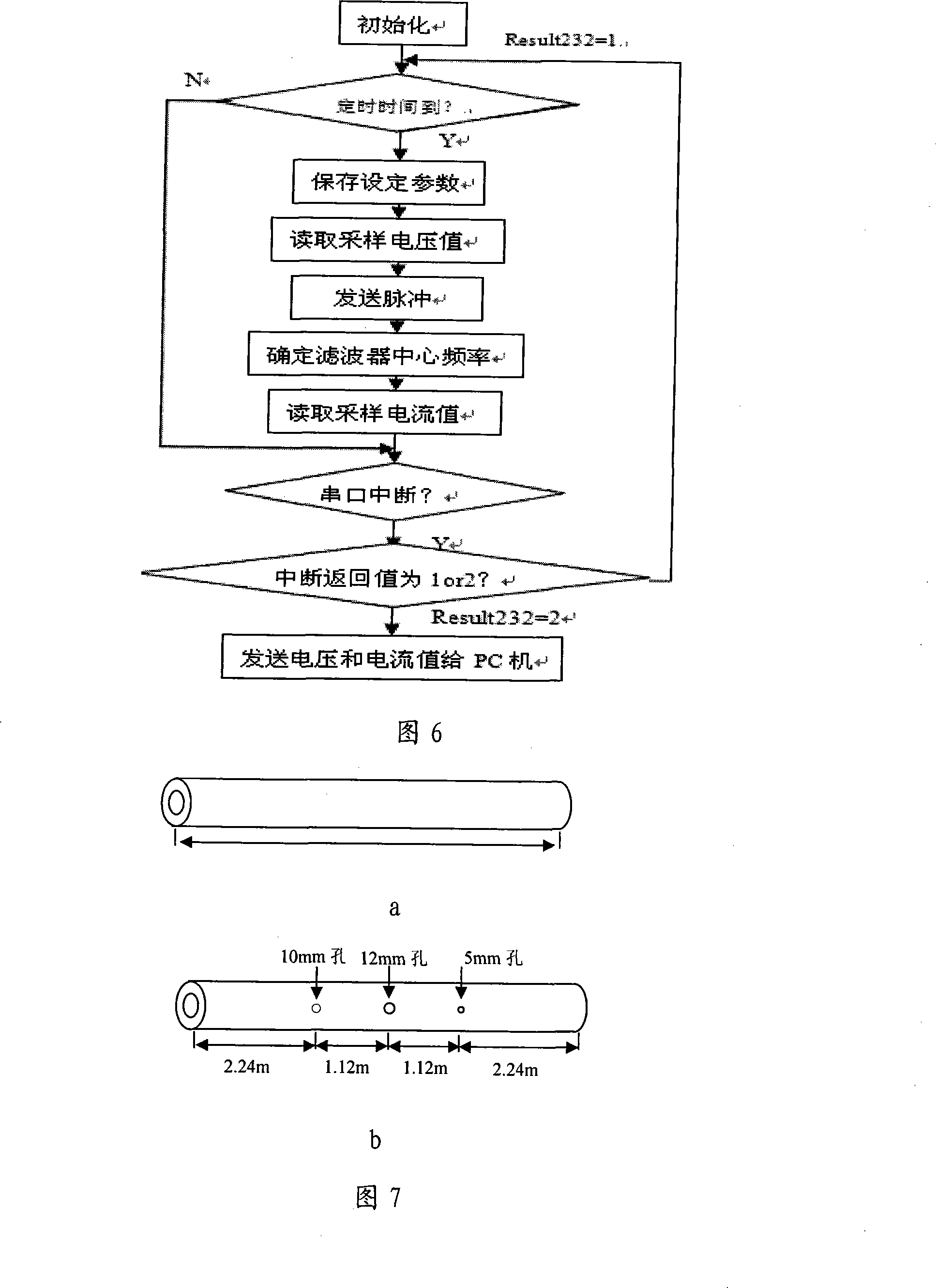

[0044] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

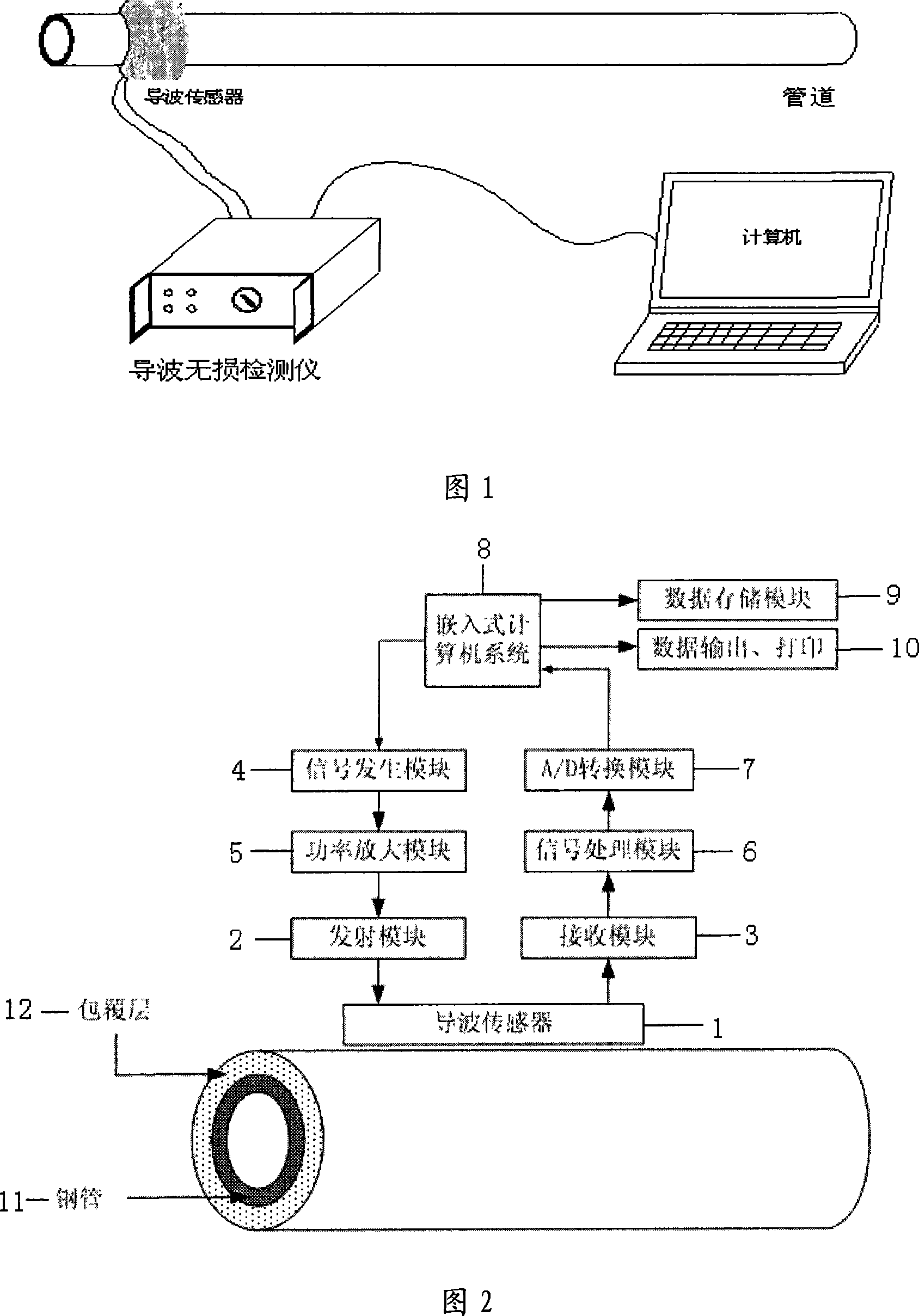

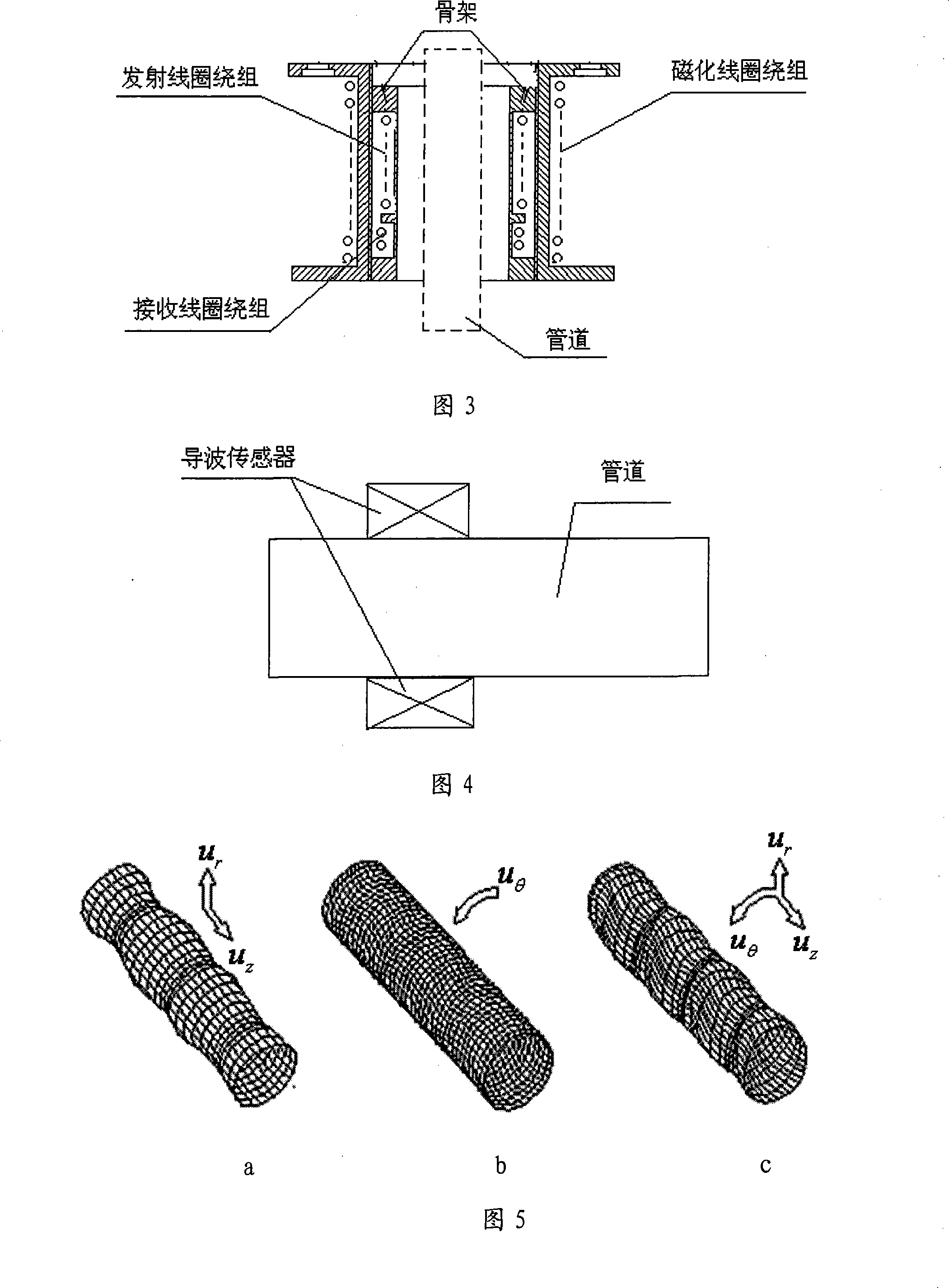

[0045] The present invention includes: guided wave sensor 1, transmitting module 2, receiving module 3, signal generating module 4, power amplifier module 5, signal processing module 6, A / D conversion module 7, and embedded computer system 8 (Figure 2). The input end of the transmitting module 2 is connected to the power amplifier module 5, the output end of the receiving module 3 is connected to the signal processing module 6, the output end of the transmitting module 2 and the input end of the receiving module 3 are both connected to the guided wave sensor 1, and the signal generation module The output end of 4 is connected to the power amplifier module 5, and the input end of the A / D conversion module 7 is connected to the signal processing module 6. In addition, the input end of the signal generation module 4 and the output end of the A / D conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com