Non-contact ultrasonic thermal-excitation infrared imaging nondestructive detection method and system

A technology of infrared thermal imaging and non-contact ultrasound, which is applied in the generation of ultrasonic/sonic/infrasonic waves, material defect testing, etc., can solve the problems of low detection success rate, easily damaged test pieces, and large noise, and achieve easy interpretation, The effect of low noise and high energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to better understand the shape, structure, and features of the present invention, preferred embodiments are listed below and described in detail with reference to the accompanying drawings.

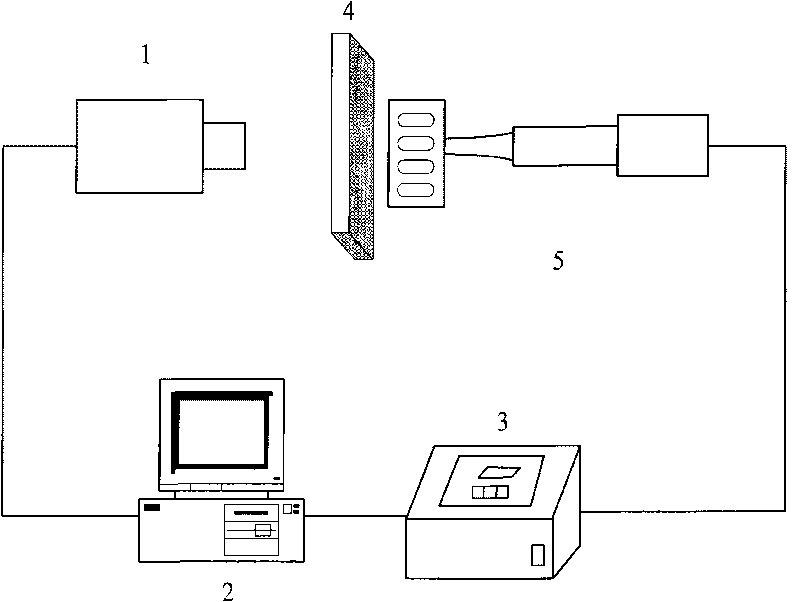

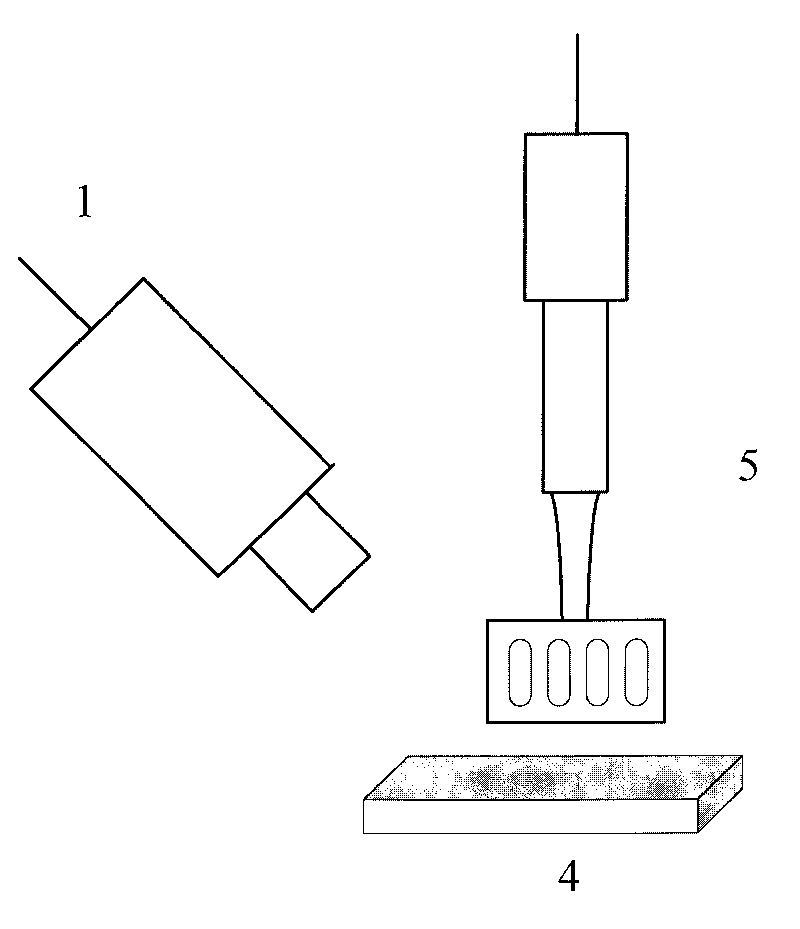

[0035] In the non-contact ultrasonic thermal excitation infrared thermal imaging non-destructive testing system and testing method of the present invention, the inspection principle is that the ultrasonic controller 3 controls the ultrasonic transmitter 5 to emit ultrasonic waves with a preset frequency, and the ultrasonic gun of the ultrasonic transmitter 5 Air is used as the coupling medium between the head and the test piece 4 to implement non-contact coupling, and short ultrasonic pulses are applied to the surface of the test piece 4.

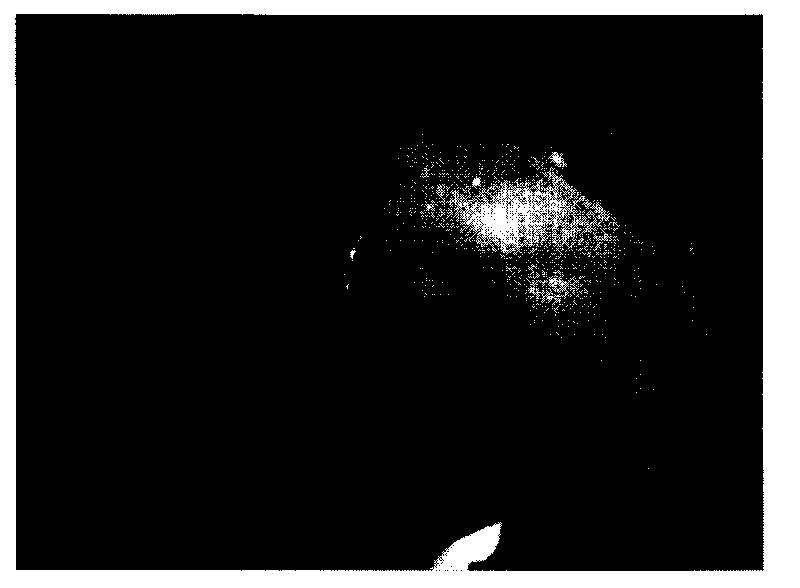

[0036] After the sound wave propagates to the test piece 4, if the test piece 4 has defects such as cracks, lack of fusion, delamination, etc., due to the friction, thermoelastic effect, and hysteresis effect at the defect site, the mechanica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com