Machining method of worm gear type pivoting support

A technology for slewing bearings and processing methods, which is applied in the field of slewing bearing processing, can solve the problems of double-raceway slewing bearings that are prone to failure, occupy a large installation space, and have a large volume of slewing bearings, so as to improve transmission efficiency and service life, occupy installation space, etc. Effect of space reduction, improvement of wear resistance and load carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

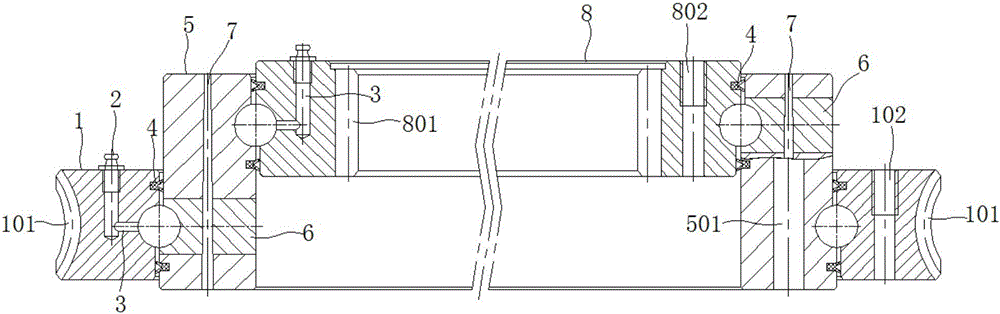

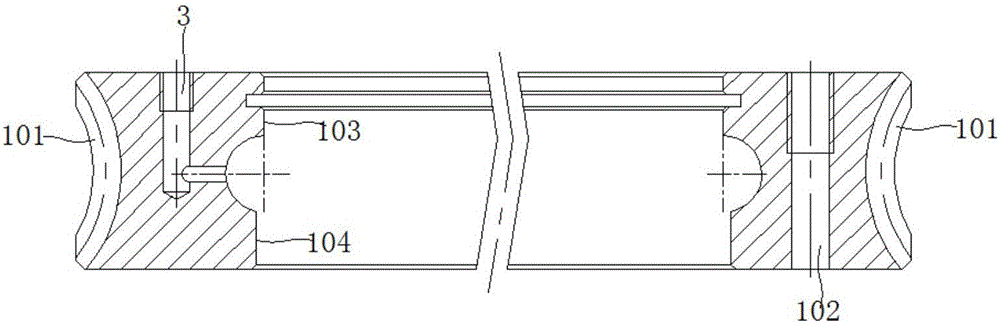

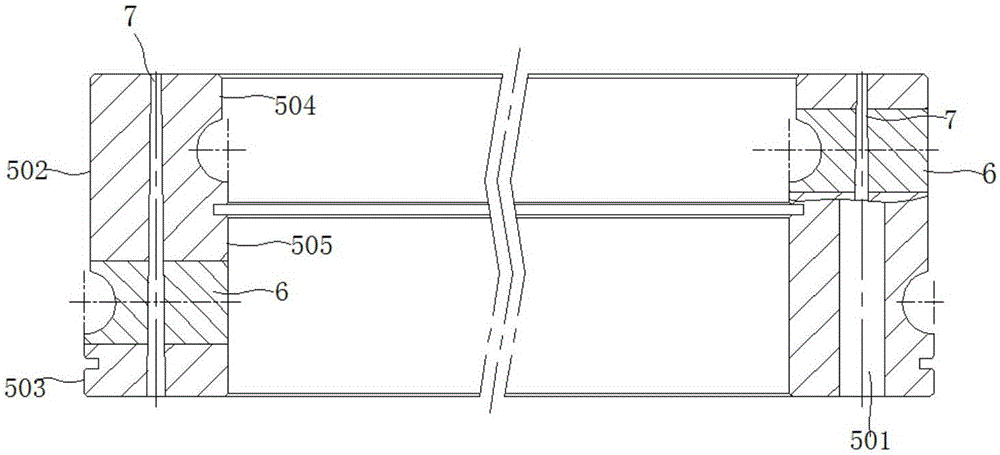

[0066] Such as Figure 1-Figure 4 As shown, a worm wheel type slewing bearing of this embodiment includes an outer ring 1, a middle ring 5 and an inner ring 8, and the rolling between the outer ring 1 and the middle ring 5 and between the inner ring 8 and the middle ring 5 Steel balls and spacers are installed in the track, so as to realize the two-way rotary motion of the slewing bearing. In this embodiment, a plugging hole is processed on the side wall of the middle ring 5, a plugging 6 is assembled in the plugging hole, and a certain number of steel balls and spacers are installed from the plugging hole, so as to align between the middle ring 5 and the outer ring 1 and between the middle ring 5 and the outer ring 1. 5 is connected with the inner ring 8, and the plug 6 and the middle ring 5 are fixed by the conical pin 7, that is, a plug is installed between the outer ring 1 and the middle ring 5 and between the inner ring 8 and the middle ring 5 6 and a tapered pin 7. In ...

Embodiment 2

[0069] Such as figure 1 As shown, a worm wheel type slewing bearing of this embodiment includes an outer ring 1, a middle ring 5 and an inner ring 8, and the rolling between the outer ring 1 and the middle ring 5 and between the inner ring 8 and the middle ring 5 Steel balls and isolation blocks are installed in the channel. Such as image 3 As shown, in this embodiment, the plugging hole is processed on the side wall of the middle ring 5, the plugging hole is assembled with a plug 6, and a certain number of steel balls and spacers are installed from the plugging hole, so as to align the gap between the middle ring 5 and the outer ring 1. And the middle ring 5 is connected with the inner ring 8, and the plug 6 and the middle ring 5 are fixed by the conical pin 7. The above-mentioned steel ball raceways are all processed into eccentric double-arc raceways, and after assembly between the outer ring 1 and the middle ring 5, and between the middle ring 5 and the inner ring 8, th...

Embodiment 3

[0077] The structure of the worm wheel type slewing bearing of this embodiment is the same as that of Embodiment 2, and the process flow chart of the processing method of the slewing bearing is shown in Figure 5 , including the following steps:

[0078] A. The processing procedure of outer ring 1 is: rough turning—semi-finishing turning—heat treatment (raceway quenching)—finishing turning—gear hobbing (worm gear hobbing)—marking—drilling—turning and grinding, and the specific details of each process The processing process is as follows:

[0079] 1. Rough car

[0080] 1. Take the ring-shaped blank as the processing raw material, select a relatively flat plane as the rough reference, clamp the inner hole of the outer ring 1, and process the other plane to the height required by the process; then use the processed surface as the Precise benchmark, after turning over and clamping, process the unprocessed plane to the height required by the process. The plane machining allowanc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com