Grading crushing machine

A pulverizer and pulverizing cavity technology, applied in grain processing and other directions, can solve the problems of large installation space, large volume, unsuitable for small and medium-sized laboratories, etc., and achieve the effect of small installation space and small volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

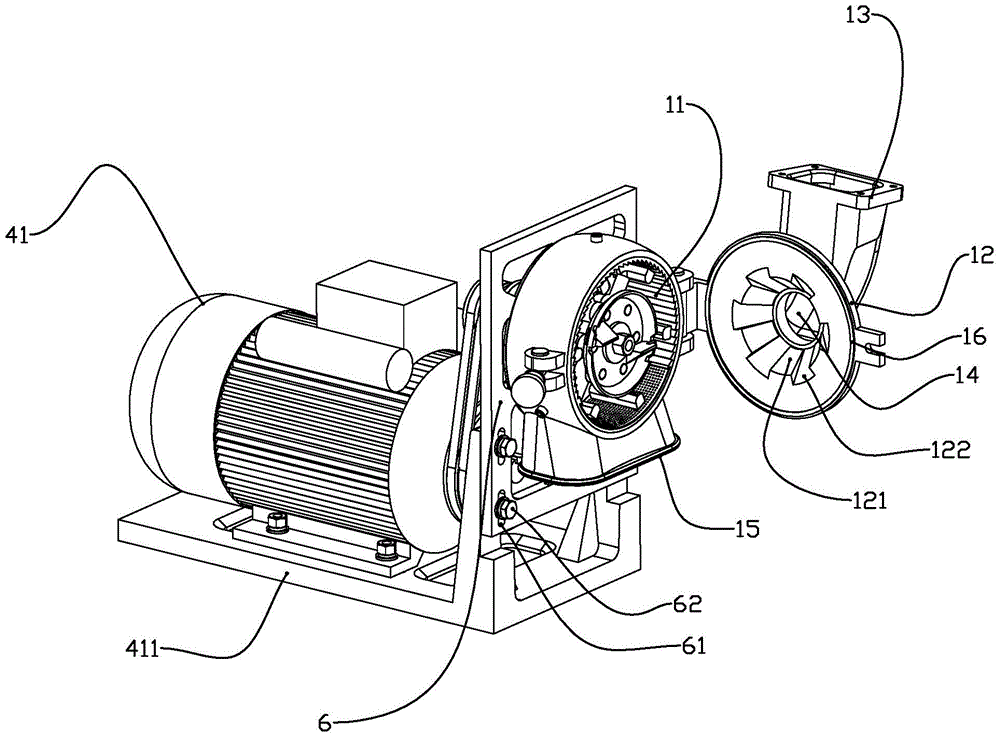

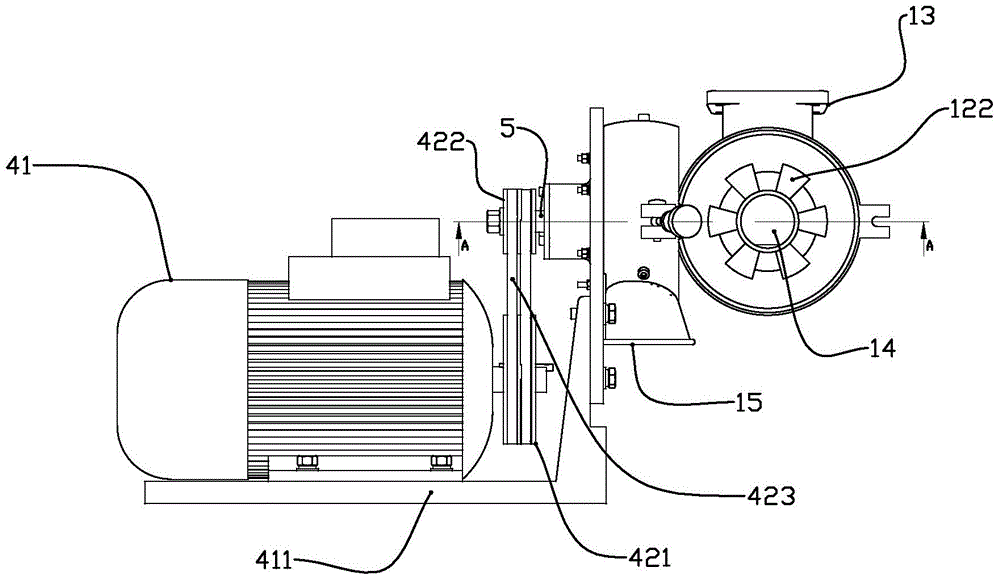

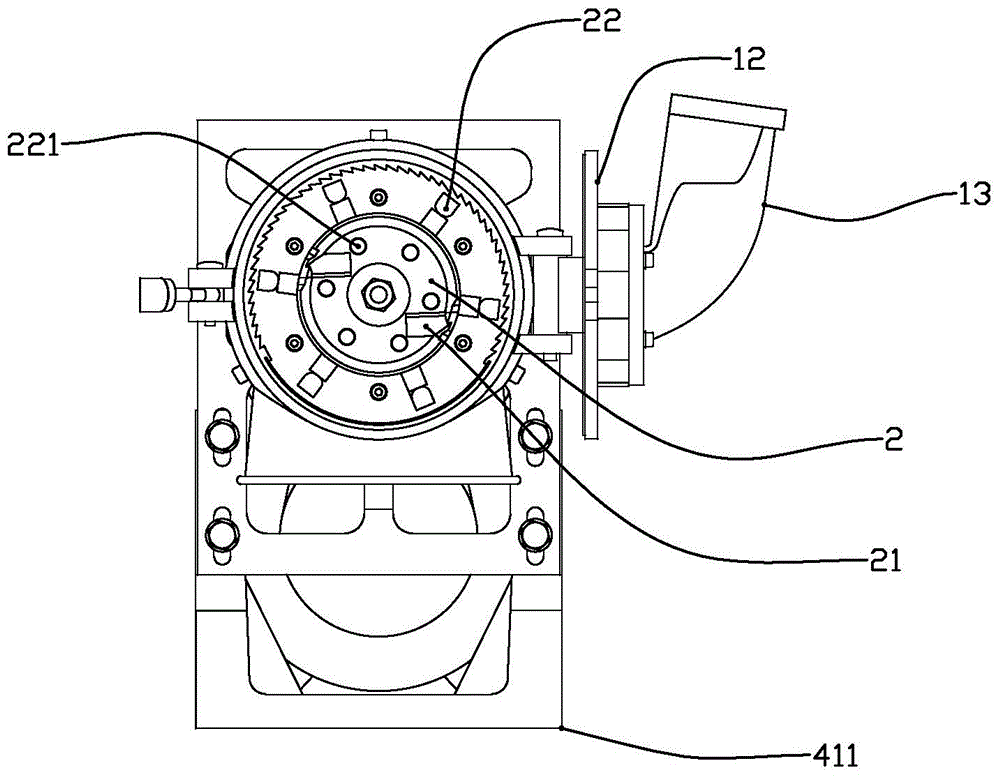

[0036] Specific embodiments of the present invention such as Figure 1-11 Shown is a classifier, comprising a crushing chamber 11, a crushing assembly and a power unit, the crushing chamber 11 is provided with a feed port 14, a discharge port 15 and a screen 3, and the crushing assembly includes a rotary table 2 provided with a hammer head 22, and the hammer The head 22 is installed on the turntable 2 through the fixed shaft 221, and the turntable 2 is connected to the power unit in transmission. The power unit includes a motor 41, and the motor 41 is fixed on the motor seat 411. The motor 41 is connected to the turntable 2 through a belt transmission assembly. The transmission assembly includes a main pulley 421, a slave pulley 422 and a transmission belt 423. The above-mentioned turntable 2 is arranged on the transmission shaft 5, the main pulley 421 is arranged on the motor 41 shaft, and the slave pulley 422 is located at the end of the transmission shaft 5. The transmission...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com