Novel clamping mechanism for washing machine tripod machining

A clamping mechanism and washing machine technology, applied in metal processing equipment, manufacturing tools, feeding devices, etc., can solve problems such as broken processing drill bits, rotation offset of washing machine tripod, hidden safety hazards, etc., and achieve the effect of guaranteed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

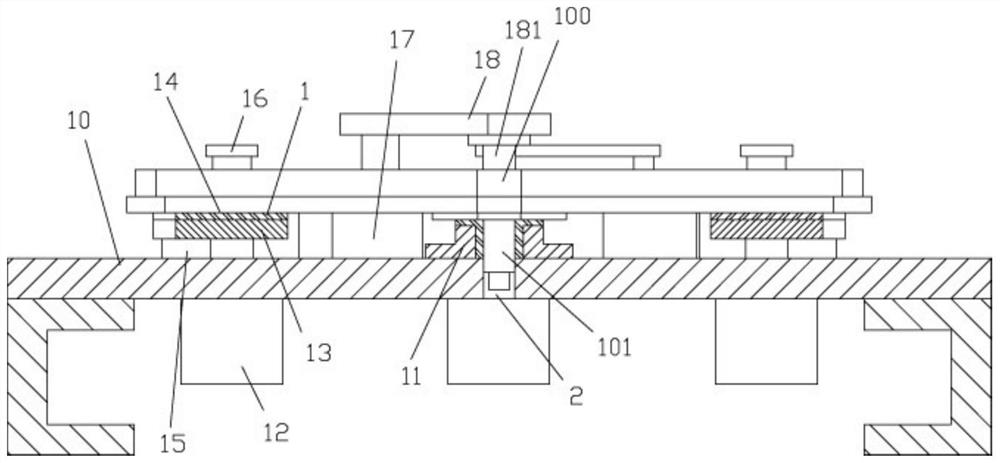

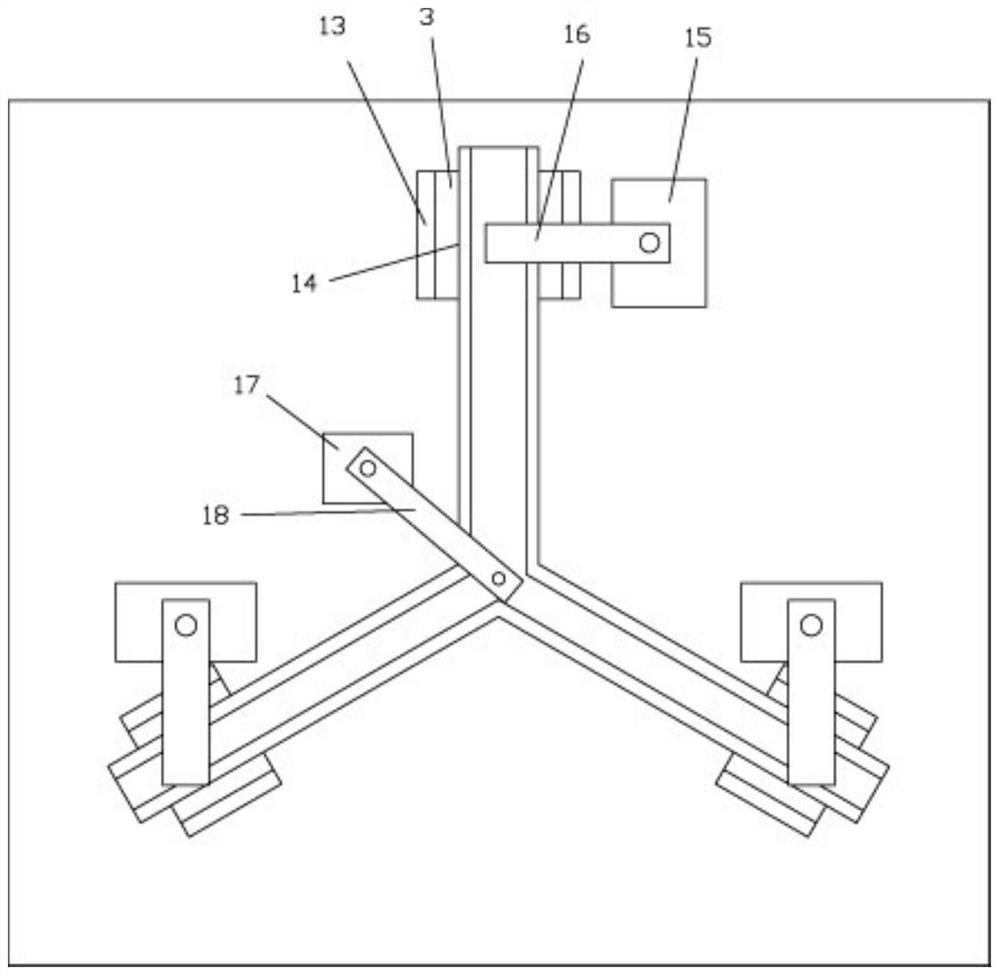

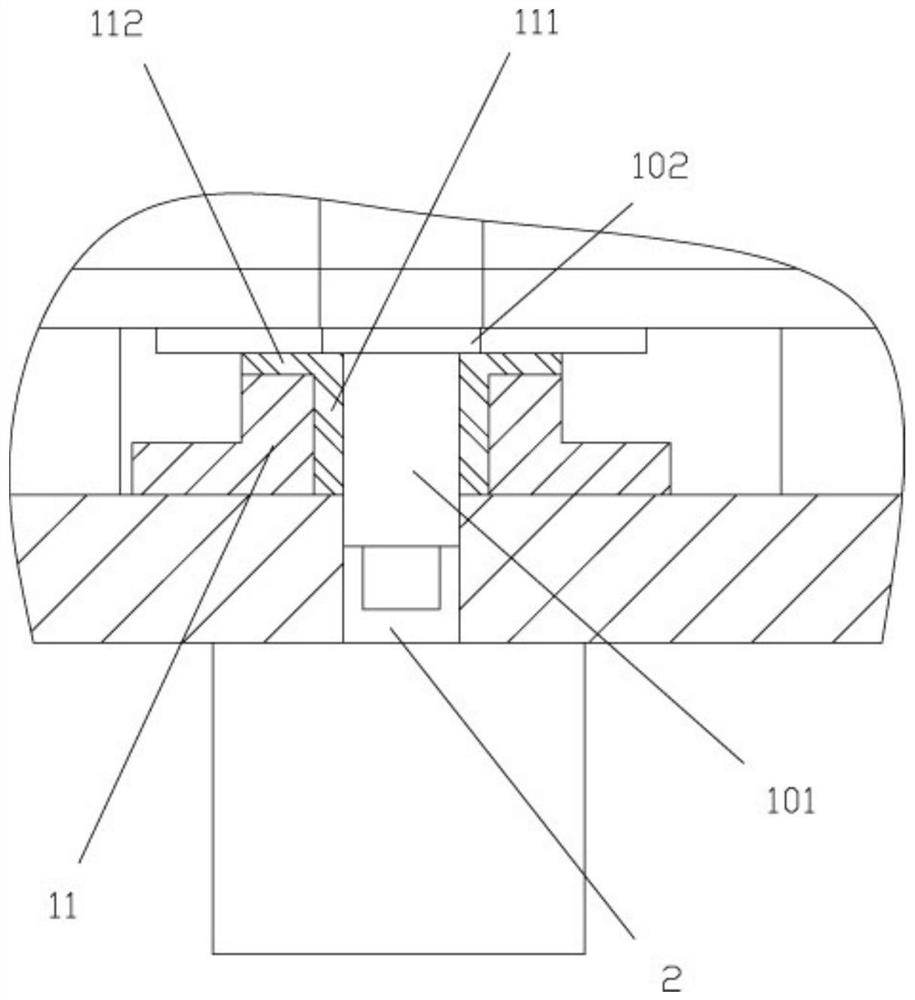

[0018] Examples, see e.g. Figure 1 to Figure 3 As shown, a new type of clamping mechanism for washing machine tripod processing includes a fixed platen 10, the middle top surface of the fixed platen 10 is fixed with a middle shaft placement sleeve 11, and the middle bottom surface of the tripod 100 to be processed is formed. The connecting shaft 101 is inserted into the middle shaft placement sleeve 11;

[0019] The fixed platen 10 is fixed with a bottom pressing cylinder 12 on the bottom surface below the ends of the three connecting support rods of the tripod 100 to be processed, and the push rod of the bottom pressing cylinder 12 passes through the top surface of the fixed platen 10 and is fixed with a The lower pressing block 13 has a slot 14 formed in the middle of the top surface of the lower pressing block 13, and the connecting support rod of the tripod 100 to be processed is inserted in the corresponding slot 14 and pressed against the bottom surface of the slot 14; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com